20

EN

20

2

3

11

INSTALLATION

11.1

Preliminary checks

• Check that the material received is in good condition and suitable for

the application.

• Check that the operating limits of the product are not exceeded.

• Check that the site chosen for installation meets the overall space

requirements of the product and that there are no obstacles hindering

open or close manoeuvres.

• Check the concrete base for the barrier installation. The base must be

cast in accordance with proper working practices, perfectly level and

clean.

11.2

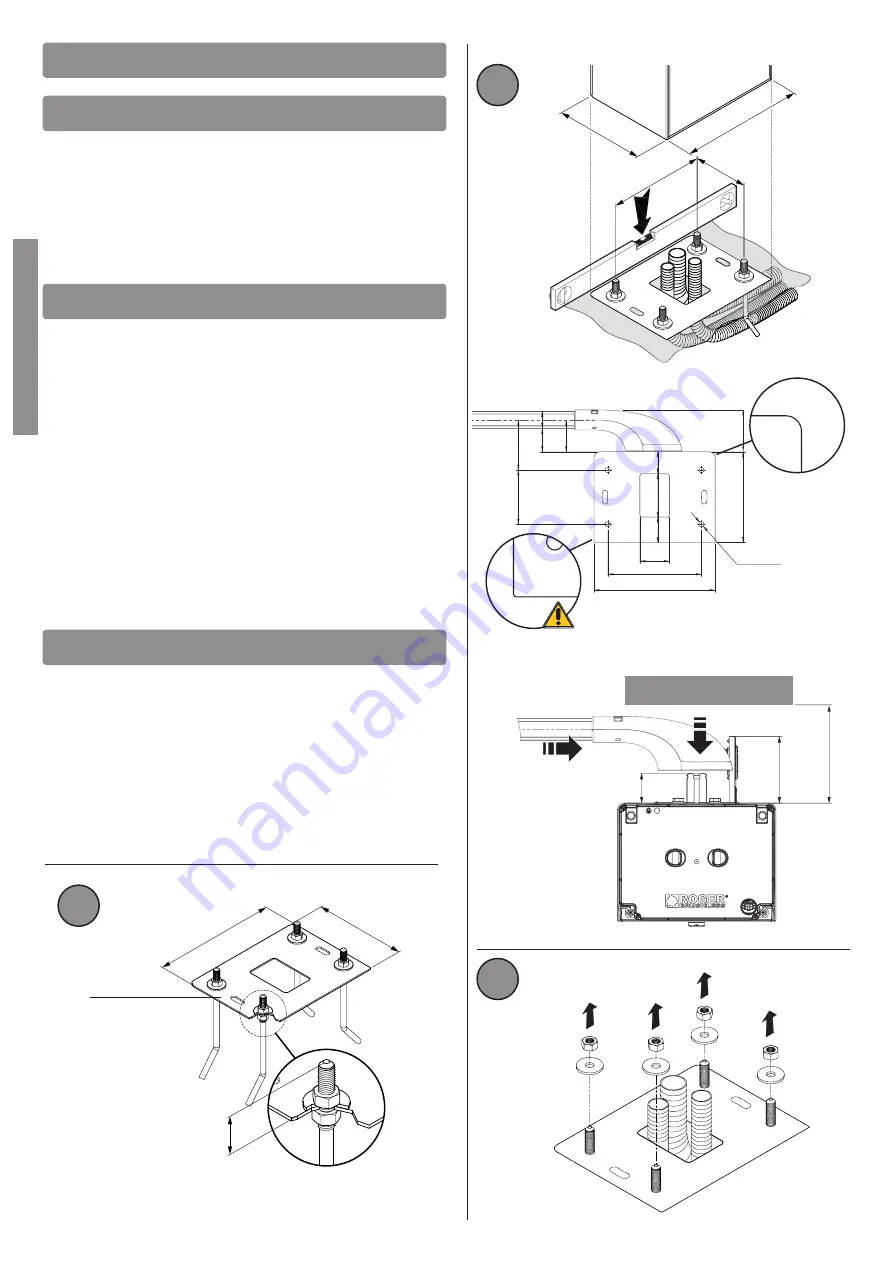

Installing base plate

The illustrations herein are indicative only. The space necessary for

fastening the automation system and the accessories may vary depending

on the overall dimensions of the installation. The installer is responsible for

determining the most suitable solution.

• Excavate a foundation pit measuring 1m x 1m x 0.4 m and fill with

concrete reinforced with steel mesh.

• Fasten the 4 anchor ties to the plate (fig. 1). N.B.: the bottom nut must

be tightened to the end of the thread on the screw so that the length Z

is at least 40 mm.

• Sink the base plate with the anchors in the centre of the foundation pit,

so that the surface is flush with the concrete and perfectly level. The

corrugated cable conduits must protrude by a few centimetres from the

centre of the plate.

PAY ATTENTION to the installation direction of the plate. See the

detailed view in fig. 2. The inspection side must be accessible from

inside the home / shop / business.

• Installation on existing surfaces. Place the base plate on the surface

and trace the positions of the fastener points. Drill the surface and fit 4

expansion anchor bolts (purchased separately).

11.3

Installing the barrier

N.B.:

the barrier is configured by default for installation on the right hand

side (viewed from the inspection hatch).

• Undo and remove the washers and nuts from the anchors on the base

plate (fig. 3).

• Open the inspection hatch, turning the key clockwise 90° (fig. 4) and

remove it.

• Place the cabinet on the plate. The anchors on the base plate must fit

through the four slots.

• Fit the washers and nuts removed previously. Move the cabinet as

necessary in the slots to adjust the position of the barrier correctly.

• Tighten the nuts securely (fig. 6).

280

210

216

125

1

280

210

Z=>40 mm

KT240

97

21

0

280

59

10

0

51

11

6

12

5

4xØ12,5

216

73

68

54

40

Lato sportello di ispezione

Inspection hatch side

53

11

8

≥

160

Summary of Contents for BI/004

Page 1: ......