HRT82PB Installation Guide Rev.C.doc

2016-10-10

3/5

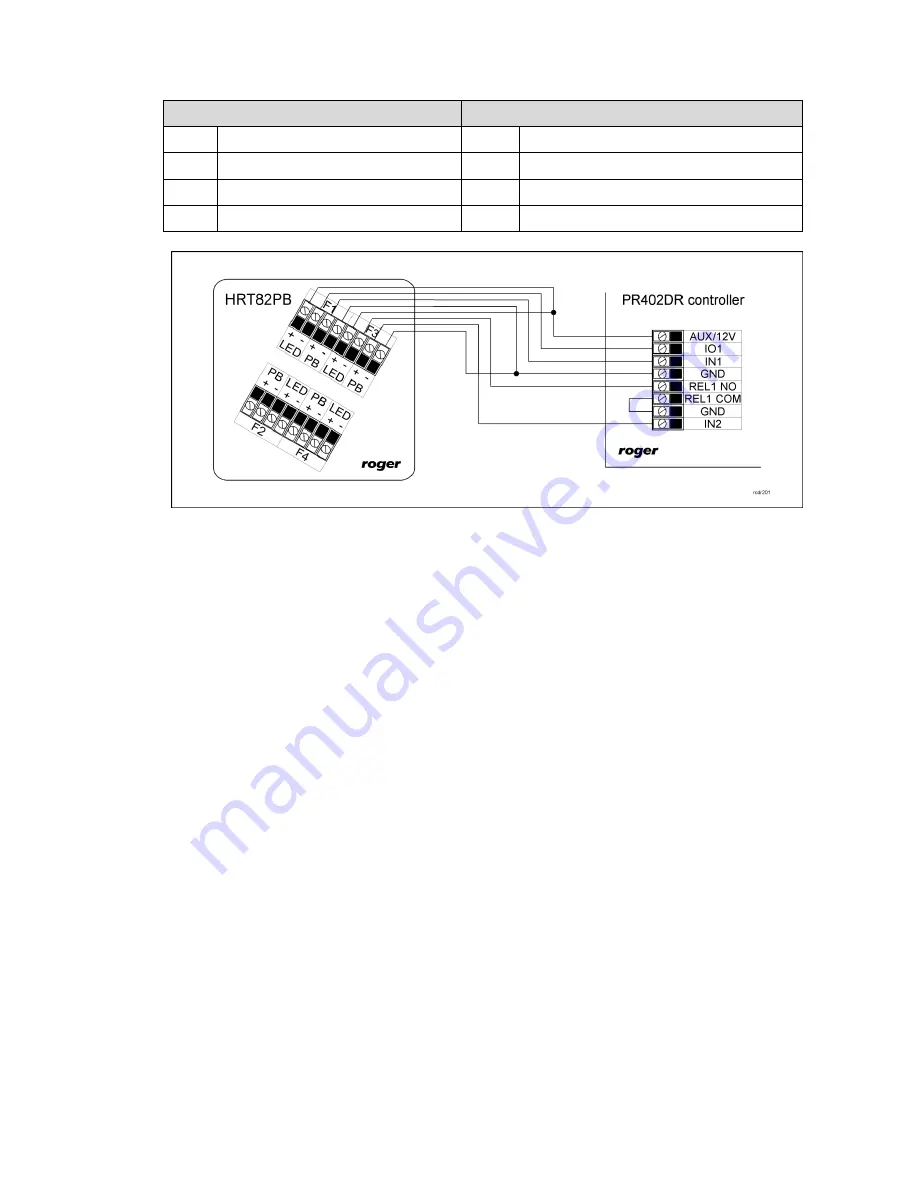

F3

F4

LED+ F3 LED + terminal, +12VDC

LED+

F4 LED + terminal, +12VDC

LED-

F3 LED – terminal, GND

LED-

F4 LED – terminal, GND

PB+

F3 button contact (SPST-NO)

PB+

F4 button contact (SPST-NO)

PB-

F3 button contact (SPST-NO)

PB-

F4 button contact (SPST-NO)

Fig. 2 Example of connection to PR402DR controller

3.2 Front panel

LED indicators

In the area of each button there is located red LED indicator. Each indicator can be switched on by

supplying 12VDC from external source. Indicator is controlled by means of transistor open collector

type output or by means of relay output (see fig. 2). Roger controller outputs can be programmed

by assigning available functions. In practical applications, indicator is logically associated with

button in order to signal that the button was used and adequate function or state was activated.

Push buttons

HRT82PB panel is equipped with four push buttons. Each SPST-NO type button offers isolated

NO/0,125A/48VDC contact which can be used to control the input of controller or low power load

point (up to 5VA). Roger controller inputs can be programmed by assigning available functions.

3.3 Wall mounting and installation guidelines

HRT82PB consists of front panel and base which are factory assembled and require manual

disassembly prior to installation according to fig. 3.

Installation guidelines

Install device on wall far from sources of heat and moisture

It is recommended to install device on Ø60mm flush mounting box

All electric connections must be made with power supply switched off

Run connection wires through hole in device base and then connect wires to screw terminals

Front panel can be regularly cleaned with wet cloth and mild detergent. Do not clean by means

of abrasive materials and strong cleaners like alcohols, solvents, etc.

Damages resulting from improper maintenance or use are not covered by warranty