10

The PLC monitors oil temperature which is displayed on the HMI. A warning is provided

as the temperature approaches maximum operating temperature and a shutdown if it

reaches the limit.

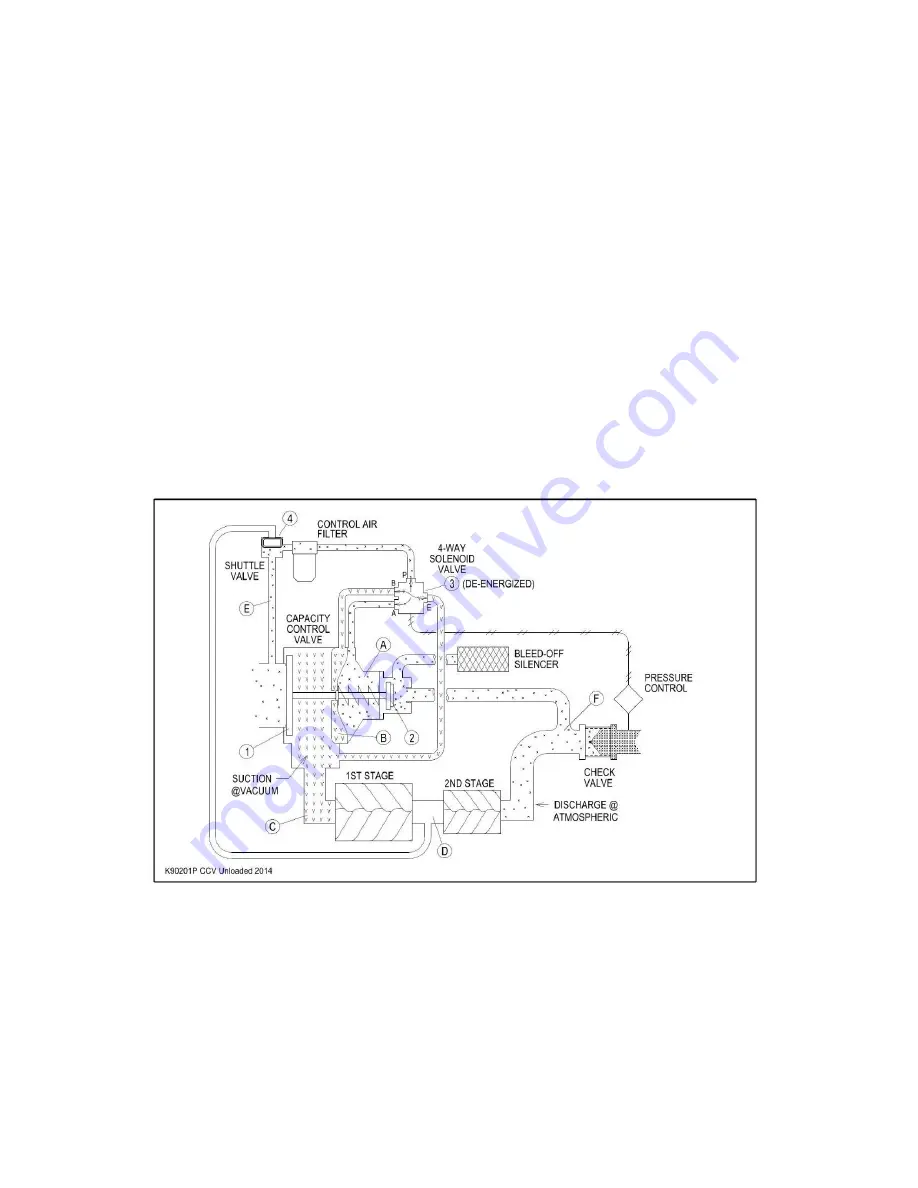

1.5. Capacity Control System

The capacity control system consists of an inlet capacity control valve (CCV) with an

integral bleed-off valve, a 4-way solenoid valve, and a shuttle valve. Opening (loaded)

and closing (unloaded) of the CCV is directly controlled by the pressure difference in two

chambers separated by a diaphragm. Pressure to the spring chamber (A) and operating

chamber (B) is regulated by the 4-way solenoid valve, which is controlled by the PLC.

The PLC monitors compressor operating conditions and compressor outlet air pressure

to determine when loaded or unloaded operation is required.

When the compressor is off, the spring in the CCV holds the inlet valve (1) closed and

the bleed-off valve (2) open. The 4-way solenoid valve (3) is de-energized. When the

compressor is started, vacuum at the operating chamber (B) helps hold the CCV in the

unloaded position.

The compressor remains unloaded after the compressor drive motor starts. After the

engine warms up and reaches full speed, load control is enabled.

FIGURE 4 - COMPRESSOR UNLOADED

To load, the 4-way solenoid valve (3) energizes, the CCV spring chamber (A) is

disconnected from atmosphere and is connected to 1st stage inlet vacuum. The vacuum

in spring chamber (A), and on the inside of the inlet valve disc, help to pull the inlet valve

(1) open while closing the bleed-off valve (2).

Air is now drawn into the compressor stages through the inlet air filter, compressed, and

discharged through the check valve to the air piping system. As air is compressed,