24

2.4. Location

The unit should be installed in a well-ventilated location, free from excessive dust. Do not

install in an area where chlorine gas, hydrogen sulfide gas, sulfur dioxide gas, highly

concentrated ozone, or any other toxic, corrosive or flammable gasses are present. It is

important to provide a source of clean intake air.

Any contaminates in the atmosphere

will be compressed with the air.

The compressor must be protected against freezing and excessive ambient

temperatures. It is equipped with freeze protection, but it must be attached to an

energized source of 120VAC power to function (located on side of compressor near

external Diesel tank connections, see

Figure 6B/6C

). The unit should be in a position

that prevents the HMI, on the end of the compressor, from being exposed to direct

sunlight.

The doors open fully and can be latched open. For ease of maintenance provide ample

clearance around the compressor. If possible, overhead clearance for lifting apparatus

should be available, per the drawing in

Chapter 2.2

. The minimum recommended

service clearances are generally the width of the doors themselves. Keep items such as

external fuel vessels and receiver tanks far enough away that the doors can open fully

and be latched in their fully open position.

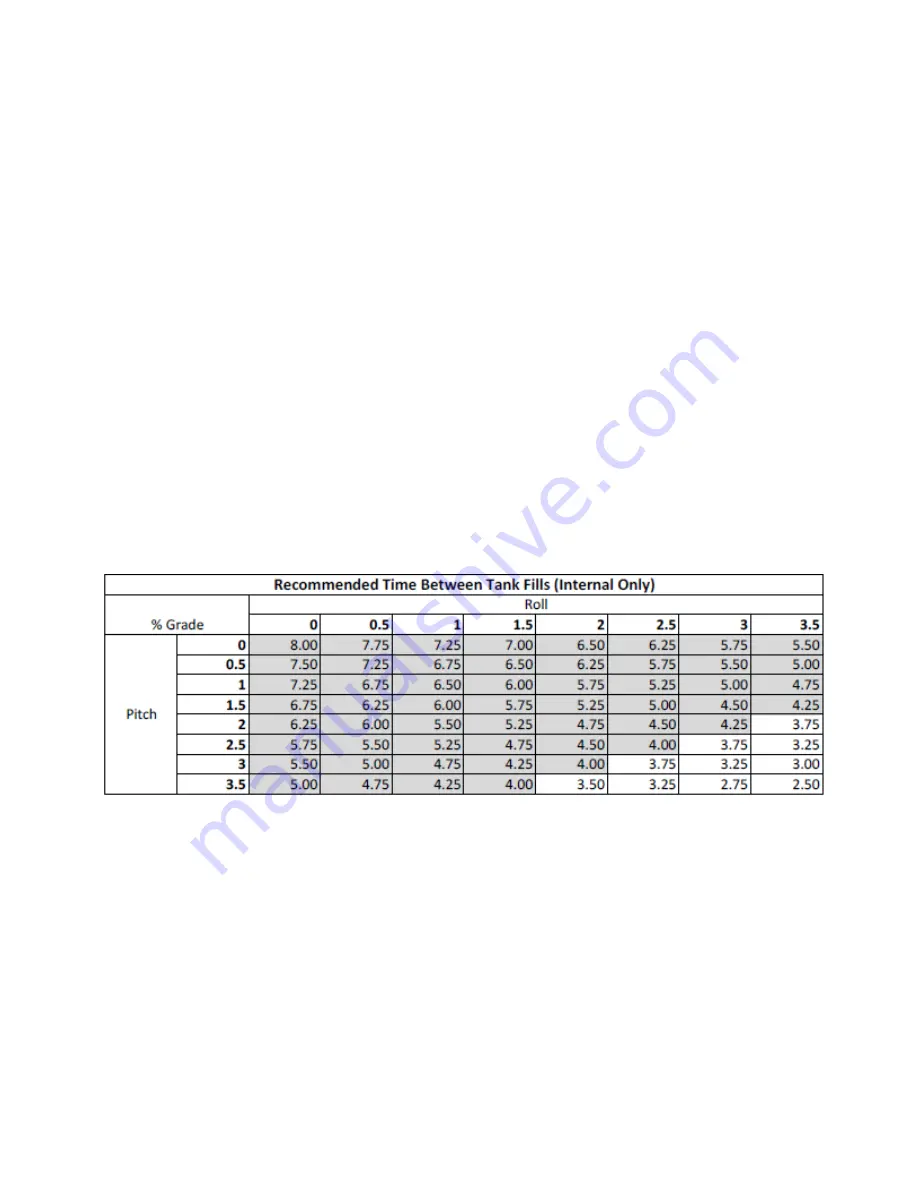

The compressor assembly should be installed in a level location as much as possible.

Note that if the assembly is not level, the run time is reduced due to fuel being stuck in

lower parts of the tank, away from the fuel pick up. Even if an external tank is connected,

the compressor should be placed on a grade of less than 3.5% regardless.

TABLE 1 – FUEL TANK ANGLE DERATE (% grade / hours)

2.5. Cooling Air

The compressor should be located where sufficient ventilation is available to cool the

compressor. The cooling air inlet and discharge must not be blocked. The warm air

exiting the cooling air outlet must be prevented from being drawn into the cooling air inlet

or compressor air inlet. Ventilation may need to be provided if the ambient temperature

exceeds 104°F (40°C) during compressor operation.

2.6. Compressor Air Outlet Piping

The compressor is equipped with an internal check valve. Compressor outlet air

pressure is controlled by the PLC monitoring an internal pressure transmitter.