37

b. Inspect starter motor.

6.11. Every 5000 Service Hours

a. Clean ARD spark plug (part of aftertreatment system).

b. Replace DEF filter.

c. Replace DEF injector.

d. Clean Diesel particulate filter.

6.12. Every 6000 Service Hours or 3 Years

a. Add engine coolant extender (ELC).

6.13. Every 10,000 Service Hours

a. Replace DEF manifold filters.

6.14. Every 12,000 Service Hours or 6 Years

b. Change coolant.

6.15. Lubrication Oil

6.15.1 Compressor Oil

The correct oil for compressor lubrication is a quality turbine oil, containing rust and

oxidation inhibitors and corresponding to ISO VG 68. DO NOT mix different brands or

grades of oil. The compressor was initially filled with

fully-synthetic

76 Products

Company turbine oil ISO VG 68 having a viscosity of 336 SUS @ 100

°

F (38

°

C). If the

need arises to add oil and this brand is not available, drain completely and refill with a

suitable replacement.

DO NOT MIX OILS.

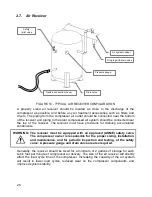

WARNING: Do not add or drain oil while the compressor is operating. The

compressor must be off, and power disconnected, before servicing can

be performed. For the safety of the maintenance personnel, lock-out and

tag out procedures must be strictly followed.

The capacity of the lube oil system is approximately 24 gallons (91 liters) for this model.

The oil level viewed on the sight gauge will vary when the compressor is operating. Fill

the sump to the upper limit of the gauge then run the compressor. Stop the unit and add

oil as necessary to maintain the oil level near the center of the sight gauge while the

compressor is running.

6.15.2 Cat DEO (Diesel Engine Oil)

Due to significant variations in the quality and in the performance of commercially

available oils, Caterpillar makes the following recommendations:

•

Cat DEO-ULS (Diesel Engine Oil Ultra Low Sulfur) (SAE 5W-40)

•

Cat DEO-ULS (Diesel Engine Oil Ultra Low Sulfur) (SAE 10W-30)

•

Cat DEO-ULS (Diesel Engine Oil Ultra Low Sulfur) (SAE 15W-40)