39

Important Notes

39

Important Notes

The product may be operated only under the operating

conditions and in the positions specified by the manufac-

turer, without the product’s ventilation being obstructed.

If the manufacturer’s specifications are not observed, this

can result in electric shock, fire and/or serious personal in-

jury, and in some cases, death. Applicable local or national

safety regulations and rules for the prevention of accidents

must be observed in all work performed.

The measuring instrument is designed for use in the fol-

lowing sectors: Industry, residential, business and com-

mercial areas and small businesses.

The measuring instrument is designed for indoor use only.

Before each measurement, you need to verify at a known

source if the measuring instrument functions properly.

1.6 Ambient Conditions

The allowed operating temperature ranges from +0 °C

to +40 °C (pollution category 2). The maximum relative

humidity (without condensation) is at 80%. During storage

and transport, the temperature must be between -40 °C

and +70 °C. In case of condensation during transportation

or storage, the instrument will require approximately two

hours to dry and reach the appropriate temperature prior

to operation. The measuring instrument is designed for

use in a clean and dry indoor environment. Do not operate

with high dust and humidity levels, if danger of explosion

exists or with aggressive chemical agents. Any operating

position may be used; however adequate air circulation

must be maintained. For continuous operation, a horizontal

or inclined position (integrated stand) is preferable.

To disconnect from the mains, the low-heat device socket on the

back panel has to be unplugged.

The maximum operating altitude for the instrument is

2000 m. Specifications with tolerance data apply after a

warm up period of at least 30 minutes at a temperature of

23 °C (tolerance ±2 °C). Specifications without tolerance

data are average values.

The heat produced inside the R&S®HMC804x is guided to

the exterior via temperature-controlled fan. Each channel

has its own temperature sensor which checks the heat

generation in the instrument and controls the fan speed.

However, it is necessary to ensure that there is sufficient

space on both instrument sides for the heat exchange.

If the temperature inside the instrument still increases to

more than ~80 °C, a channel-specific overheat protec-

tion intervenes. Affected outputs will automatically be

switched off.

1.7 Maintenance

The display may only be cleaned with water or an appro-

priate glass cleaner (not with alcohol or other cleaning

agents). Follow this step by rubbing the display down with

a dry, clean and lint-free cloth. Do not allow cleaning fluid

to enter the instrument. The use of other cleaning agents

may damage the labeling or plastic and lacquered sur-

faces.

1.8 Warranty and Repair

ROHDE & SCHWARZ instruments are subject to strict

quality controls. Prior to leaving the manufacturing site,

each instrument undergoes a 10-hour burn-in test. This is

followed by extensive functional quality testing to examine

all operating modes and to guarantee compliance with the

specified technical data. The testing is performed with test-

ing equipment that is calibrated to national standards. The

statutory warranty provisions shall be governed by the laws

of the country in which the ¸ product was purchased.

In case of any complaints, please contact your supplier.

Do not obstruct the ventilation holes!

Clean the outer case of the measuring instrument at regular

intervals, using a soft, lint-free dust cloth.

Before cleaning the measuring instrument, please make sure that

it has been switched off and disconnected from all power sup-

plies (e.g. AC supply network or battery).

No parts of the instruments may be cleaned with chemical clean-

ing agents (such as alcohol, acetone or cellulose thinner)!

The product may only be opened by authorized and

qualified personnel. Prior to working on the product or

before the product is opened, it must be disconnected

from the AC supply network. Otherwise, personnel will

be exposed to the risk of an electric shock.

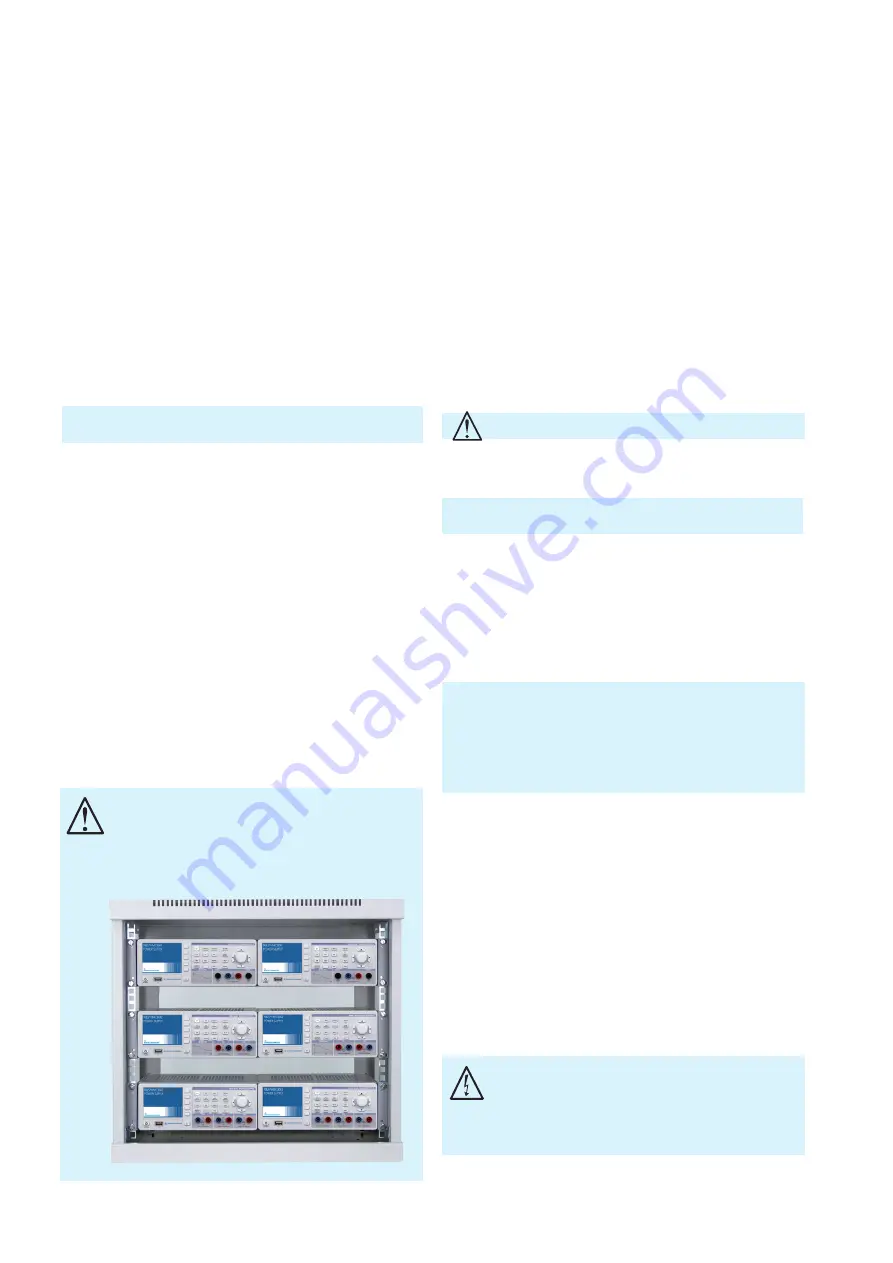

When one or more R&S®HMC804x instruments are instal-

led in a 19“ rack, it is important to ensure that sufficient

space is available for adequate cooling (see figure below).

Required minimum distance: 1 RU

www.allice.de

Allice Messtechnik GmbH

Summary of Contents for 3593.1006.02

Page 2: ...www allice de Allice Messtechnik GmbH ...

Page 3: ...71 Appendix 71 Appendix www allice de Allice Messtechnik GmbH ...

Page 37: ...35 Anhang 35 Anhang www allice de Allice Messtechnik GmbH ...

Page 39: ...www allice de Allice Messtechnik GmbH ...

Page 40: ...71 Appendix 71 Appendix www allice de Allice Messtechnik GmbH ...

Page 73: ...68 Appendix 68 Appendix www allice de Allice Messtechnik GmbH ...

Page 74: ...69 Appendix 69 Appendix www allice de Allice Messtechnik GmbH ...

Page 75: ...70 Appendix 70 Appendix www allice de Allice Messtechnik GmbH ...