46 / 191 - EN -

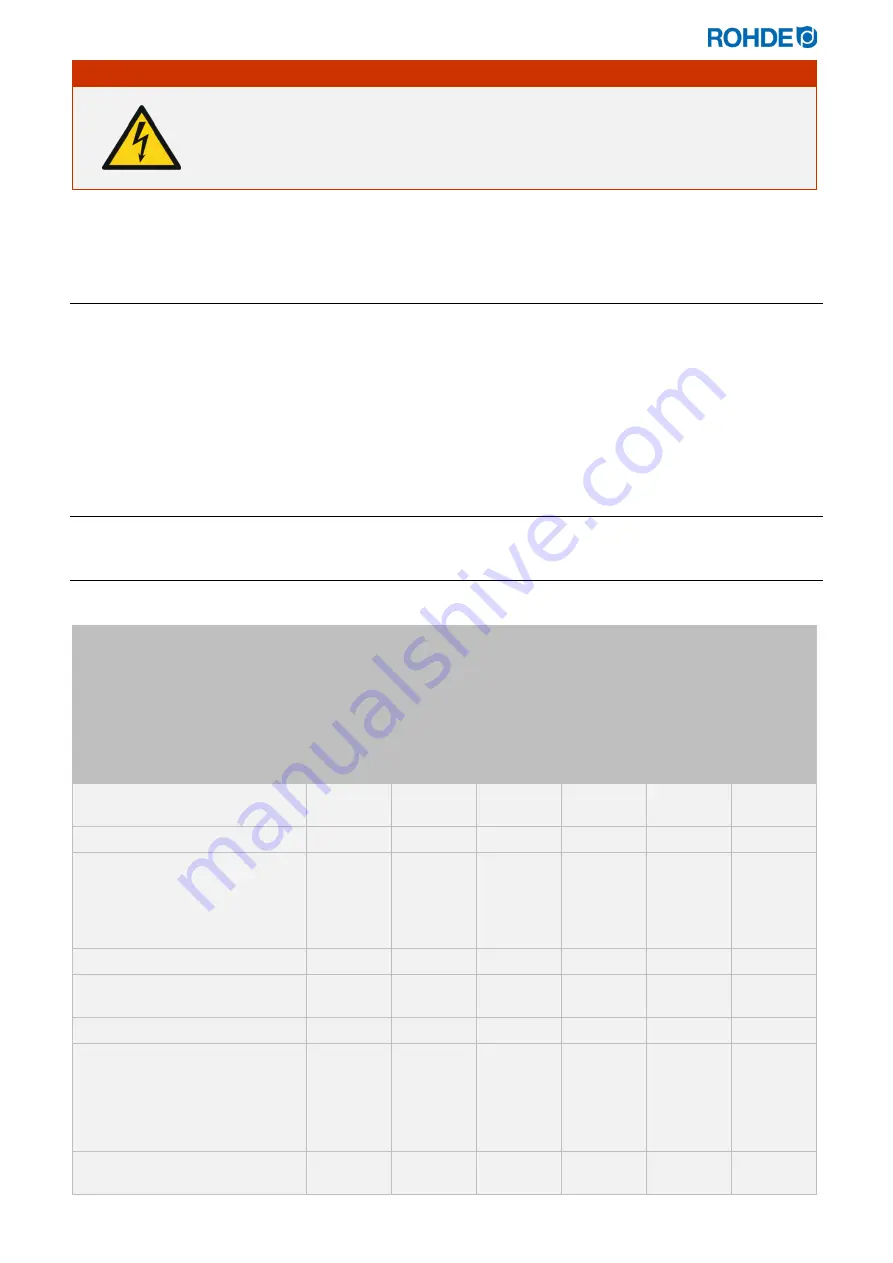

DANGER

Risk of death!

Risk of electric shock.

Maintenance work on electrical components may only be carried out by a qualified

electrician.

11.2.

General information

⇒

The pugmill is practically maintenance-free.

⇒

The drive motor is a closed system that has no lubrication points for maintenance of the machine.

⇒

In the case of the drive motor, however, the gear oil must be changed every 4,000 operating hours or 4

years, whichever comes first (see next section). During use, make a note of the operating hours or the

operating time of the machine in order to be able to comply with these intervals.

11.3.

Maintenance intervals

11.3.1.

Mechanical components

Carry out the maintenance and tests at the intervals listed below. Replace defective components immediately.

Action

B

efo

re each

us

e

A

ft

er

each

us

e

W

eekl

y

E

ve

ry

6

m

o

nths

E

ve

ry

1

2 m

o

nths

A

ft

er

4,

000

o

p

era

ting

ho

urs

o

r

ev

er

y

48

m

o

nths

Visual inspection of the safety

ring

X

Clean the pugmill

X

Visual inspection of the housing

X

Visual inspection of the mixing

shaft with wing blades

X

Visual inspection of the nozzle

X

Visual inspection of the worktable

X

Visual inspection of the cutting

device

X

Visual inspection of the controls

X

Visual inspection of the power

cord and power plug

X

Visual inspection of the screw

connections on the outside of the

housing

X

Changing the oil in the drive

motor

X

Summary of Contents for TS 20

Page 194: ...20220224 01 ...