www.rohlhome.com

INSTALLATION INSTRUCTIONS

Consult your local ROHL showroom for additional information and specifications. For complete warranty details and a list of showrooms, go to www.rohlhome.com.

Congratulations on the purchase of your Perrin & Rowe Bathroom Product. Correctly installed and with sensible

care, this product will give you many years of trouble free service.

The Georgian Bathroom Collection

Installation & User Guide

IMPORTANT INFORMATION

Before you proceed... We recommend you engage the services of a registered plumber to install

this product.

For ease of possible future servicing, we also recommend the fitting of conveniently placed

isolating valves.

In addition to the guide below it is essential that the written information overleaf is carefully read

and understood.

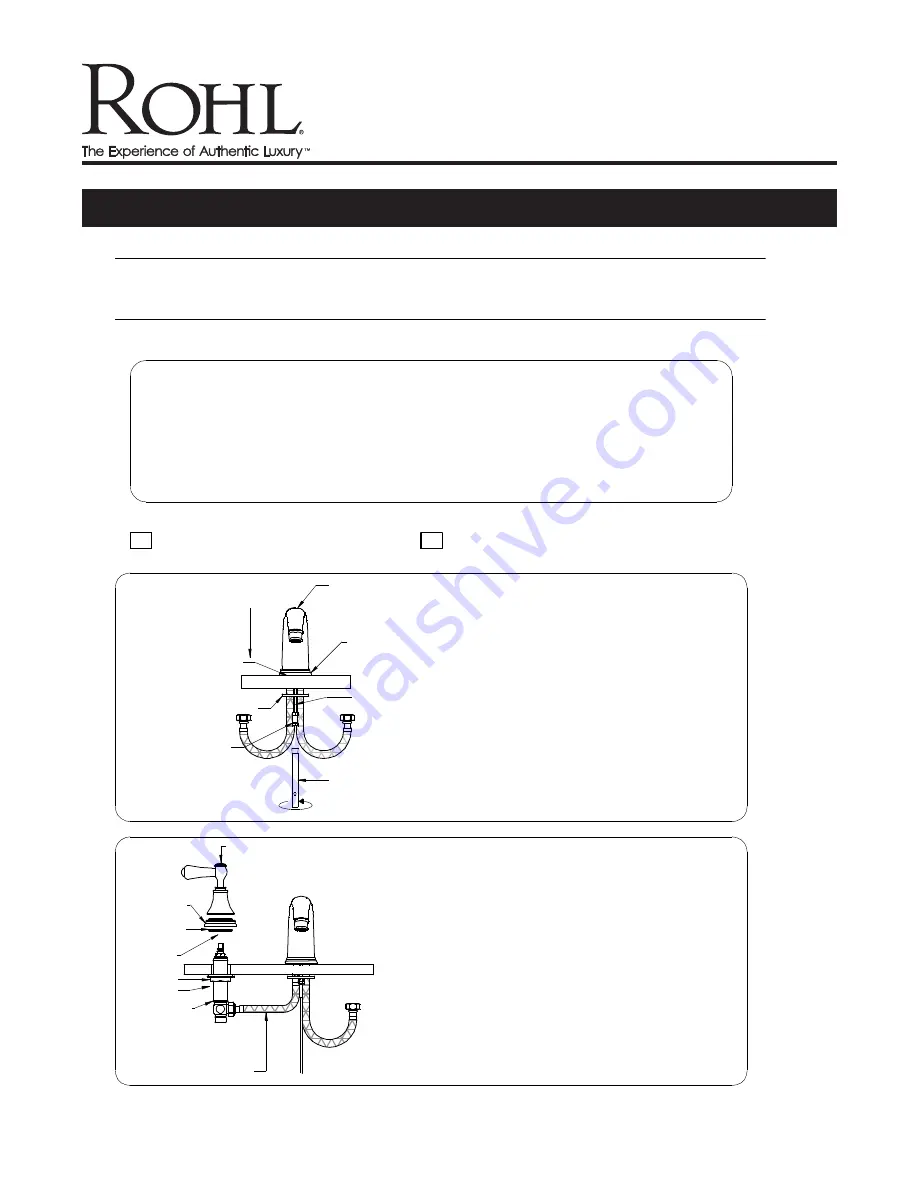

Preparation Check Box for Installer

Flush the plumbing system before

installing the bathroom product.

Once unpacked remove large & small base seals,

rosette, hood & lever, securing nut, clamp plate,

pop-up and top waste ready for installation.

1

Secure spout with supplied Box Spanner.

Ensure all connections are firmly tightened

3

Please Note: Ceramic disc valves are fitted

as standard to this mixer. Flow from FULLY

OFF to FULLY ON is achieved by rotating the

handles a quarter turn.

2

CARE & MAINTENANCE

Wipe down after use to avoid water spotting and mineral build up.

Occasional cleaning with warm soapy water, followed by a polish with a soft cloth is all that is required to keep the

plated finish in good condition.

Do not use proprietary abrasive liquids, powders, or pads to clean the shower. Do not use any products

with ammonia bleach or limescale remover. You will damage the plated finish and void your guarantee.

BEFORE USE

• Carefully check the installation for leaks.

• If further building work is to be carried out in the vicinity, cover the tap with a plastic bag to avoid damaging

the finish.

• Please ensure that the installation complies with local plumbing codes.

4

WORK SURFACE

Base Ring

Large Base

Seal

Spout

Clamp Plate

Clamp Bolt

Securing Nuts

Box Spanner

WORK SURFACE

Rosette

Small Base

Seal

Washer

Backnut

Valve Body

Flexible Hose

Hood & Lever

WORK SURFACE

Hood & Lever

Rosette

Small Base

Seal

Washer

Backnut

Valve Body

Flexible Hose

Sidevalve to be installed from underside of work surface as

shown.

Ensure connection for flexible hose is facing towards spout.

Leave backnut at the bottom of valve body and place the valve

body up through the work surface hole.

Before screwing down the hood & lever please make sure

orientation of levers is correct. Slide the hood & lever over the

top of valve body just enough to see if it is correctly

orientated.

Correct orientation can be achieved by removing and turning

the vernier insert.

Screw backnut up to the underneath of the work surface.

Connect flexible hose as shown.

WORK SURFACE

BASIN/BIDET

Connect flexible hose as shown.

Connect HOT & COLD water supplies to the side

valve inlets.

Ensure all connections are firmly tightened.

Adjusting Sink Waste

• Ensure that pop-up shaft is in position alongside pop-up

rod.

• Shaft and rod can be cut if space is restricted.

• Secure pop-up using clamp bracket.

• Adjust position of clamp bracket to achieve maximum

movement of pop-up shaft.

• Place pop-up into waste and adjust movement of

pop-up shaft.

O Ring

Pop-Up

Foam

Seal

Rubber Seal

Bottom

Waste

Pop-Up

Rod.

Clamp

Bracket

Pop-Up

Shaft

Top Waste

Vernier

Insert