7 | Maintenance

86 / 91

DURO-A RC

7.3.4

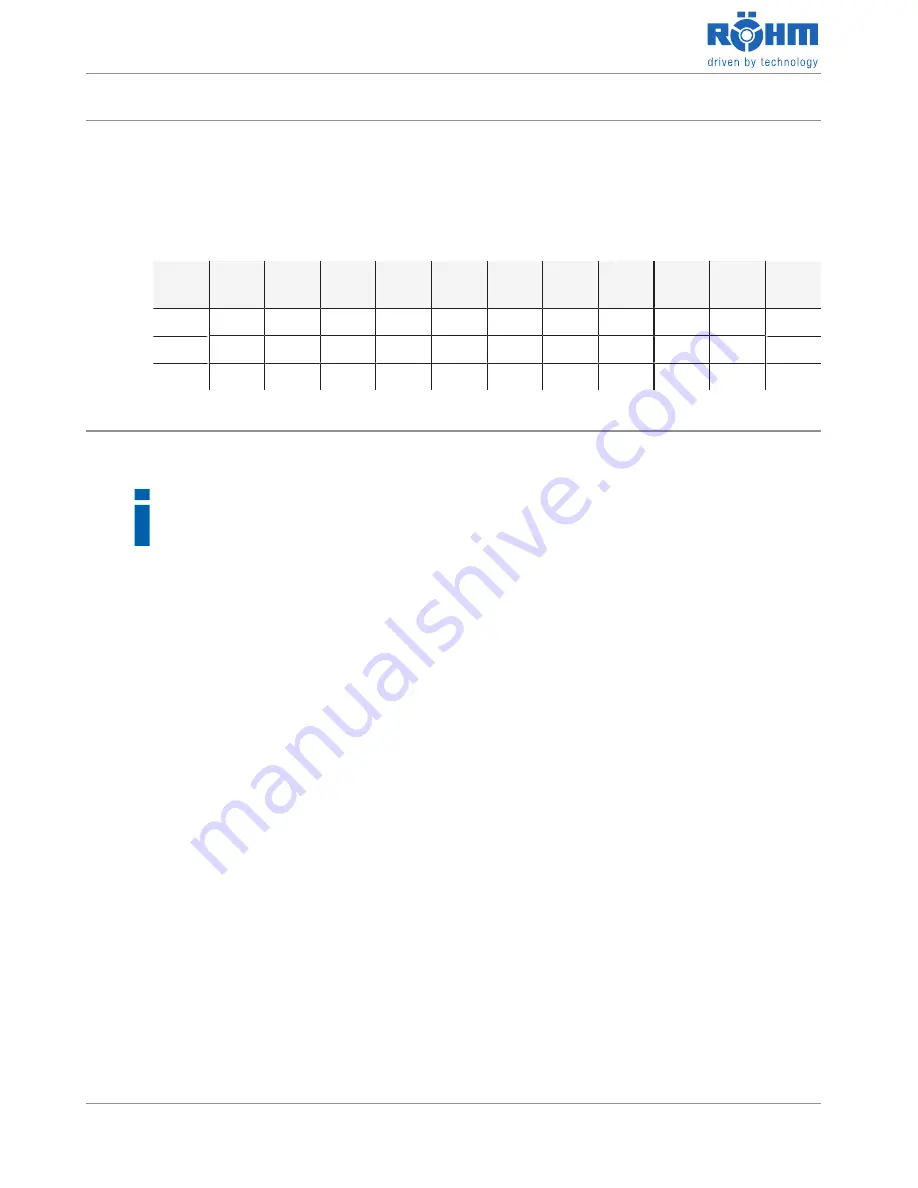

Checking the Tightness of Screw Connections

If screws are replaced or undone, incorrect replacement or attachment may

lead to dangers for persons and objects. For this reason, for all fixing screws,

the screw recommended by the manufacturer of the screw must be used and

the tightening torque applied in accordance with the screw quality.

Tightening torque in Nm

Qua-

lity

M5

M6

M8

M10

M12

M14

M16

M18

M20

M22

M24

8.8

5.9

10.1

24.6

48

84

133

206

295

415

567

714

10.9

8.6

14.9

36.1

71

123

195

302

421

592

807

1,017

12.9

10

17.4

42.2

83

144

229

354

492

692

945

1,190

7.3.5

Inspection of the Power Chuck

Warranty by Service department of RÖHM GmbH

If the annual inspection of the power chuck is carried out by the Service

department of RÖHM GmbH, the warranty is extended by up to 3 years.

If the inspection is not carried out by the Service department of RÖHM

GmbH, the extended warranty lapses.

For inspection, the power chuck must be completely dismantled, cleaned and

re-assembled. Worn or damaged components must be replaced during the in-

spection.

Disassembly and dismantling of the power chuck

1.

Move piston of the power chuck into front position.

2.

Remove jaws (1-3) from the guides (Replacing Jaws [

}

79]).

3.

Screw the crane lug into the power chuck.

4.

Correctly attach the load-bearing equipment to the crane lug.

5.

Unscrew the threaded ring of the power chuck from the draw tube with

the assembly tool provided.

6.

Undo the three chuck fixing screws.

7.

Turn the power chuck over with a crane and set down at the cleaning

area.

8.

Unscrew crane lug.

Summary of Contents for DURO-A RC

Page 2: ......