Maintenance | 7

KZS-P_KZS-PG

39 / 43

7.3.4

Checking the Clamping Force

Check clamping force with clamping force measurement system.

Recommended clamping force

measurement system

ID no.:

F-Senso Chuck

179800

7.3.5

Complete Cleaning

CAUTION

Skin irritations due to contact with lubricants.

Lubricants may cause irritations in the event of contact with the skin.

Ø

When handling the

centric clamp

, wear safety goggles, long

work clothes and gloves.

Ø

Avoid skin contact with lubricants.

For complete cleaning, the centric clamp must be removed from the machine

table, completely dismantled, cleaned and re-assembled.

Disassembly and dismantling of the centric clamp

Before dismantling, plan the required time for a leak test.

§

The machine is switched off and protected against being switched on

again.

1.

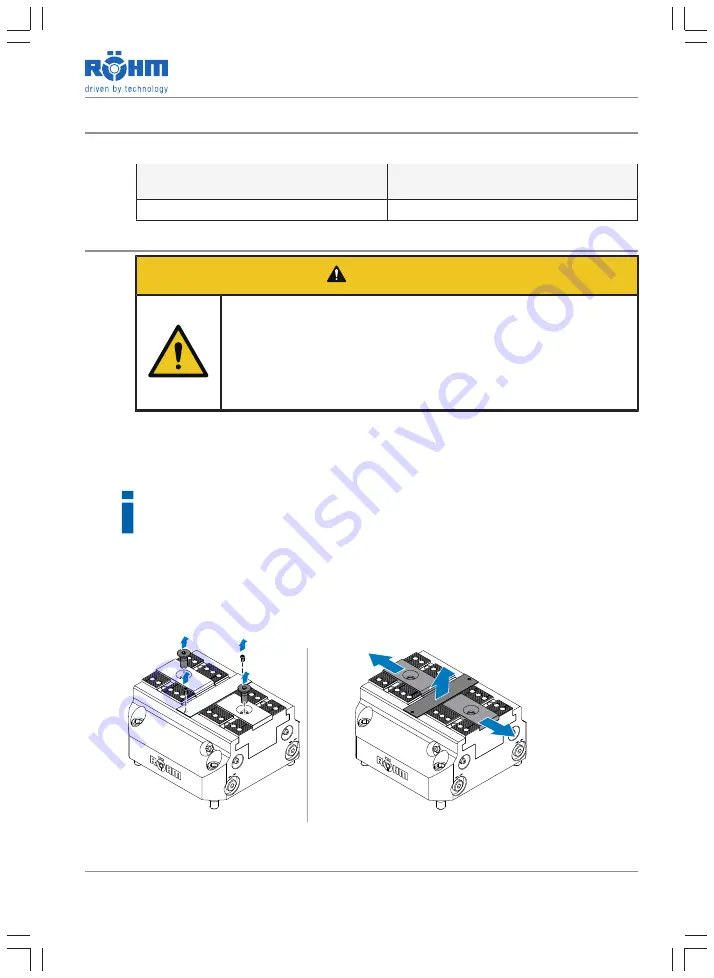

To make all screws accessible, disassemble the top jaws.

2.

Undo the screws of the cover (7) and of the guide strips (6) (A).

A

B

Summary of Contents for KZS-P

Page 2: ......