START-S12

Technical manual

-15-

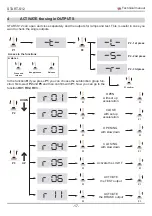

3.12 Connection of the photo-beam (activated when closing) with TEST

The TEST of the photo-beam works only if the

photo-beams are installed properly. The control

unit will check all connections before opening!

In case the photo-beam are not working pro-

perlym the control unit will lit on for 5 seconds

and the gate is not moving.

To activate the

TEST

set

1

in the

PHOTO-A:

If you go back to function without TEST, do the

connection as in Par.

3.08

and put in

0

the

S06

and

S09

(deactivate if are inputs are not in test)

S 09

TEST IN PHOTO OUTPUT

1 - Activated

0 - Deactivated

S 06

TEST IN THE INPUT

SAFETIES

1 - Activated

0 - Deactivated

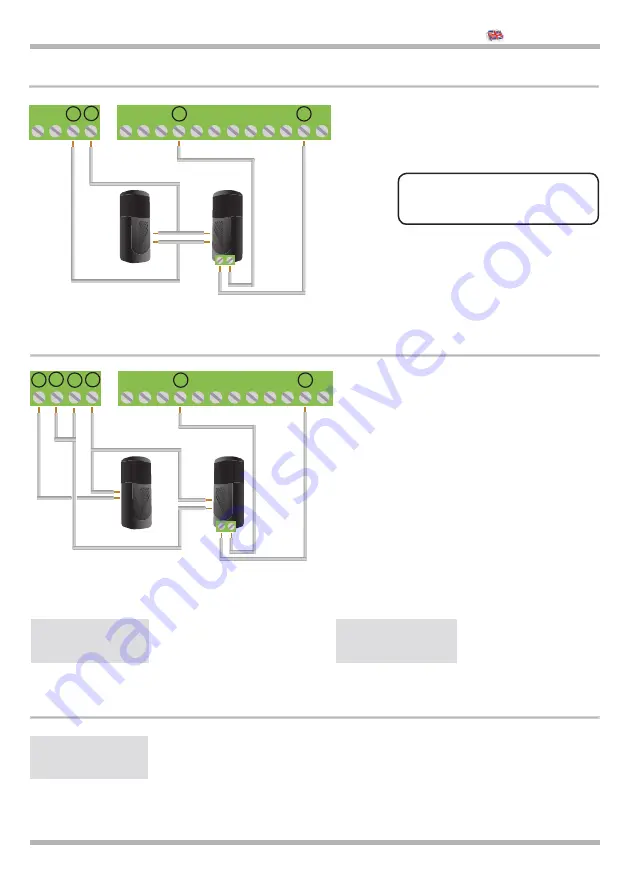

3.13 Deactivation of the PHOTOCELL A when the gate is closing

S 03

Photocell A deactivated

1 - Activated

0 - Deactivated

If you set S03 it deactivates the PHOTO A after in-

tervention of slow down LS. If

S03 is 1

the time of

function

T11

is not considered

12 13 14 15 16 17 18 19 20 21 22 23

8 9 10 11

RX

TX

NC Contact

12 Vac

The contact of the receiver should be:

- Isolated

(isolated from tensions)

- Normally closed

3.11

Connection of the PHOTO-BEAMS (only when closing)

If the input PHOTO

is not used, set S16 in 0

!

12 13 14 15 16 17 18 19 20 21 22 23

8 9 10 11

RX

TX

NC Contact

12 Vac

Summary of Contents for START-S12-M

Page 30: ...START S12 Manuale tecnico 30 10 Note ...

Page 63: ...START S12 M Technical manual 30 10 Note ...

Page 95: ...START S12 Technical manual 30 10 Note ...

Page 128: ...START S12 Instrución 31 10 Note ...

Page 129: ...START S12 Instrución 32 ...

Page 130: ...START S12 Instrución 33 ...

Page 164: ...START S12 Notice d emploi 31 10 Note ...

Page 165: ...START S12 Notice d emploi 32 ...

Page 166: ...START S12 Notice d emploi 33 ...