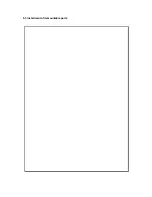

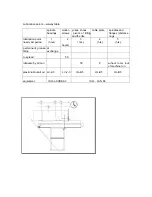

9.4 Setting of scoring saw blade

The scoring blade must be aligned with

the main blade precisely. After

releasing of arresting handle the side

adjusting of scoring saw blade is done

by turning with the screw with a hand

star. By turning to the right the scorer

moves to the right and vice versa.

Draw up the arresting handle when

ready with the scorer side adjustment.

The height of scoring saw blade can

be adjusted according to need by the

screw with a hand star and an

arresting nut. After releasing of

arresting nut by turning the screw to

the right - the scoring blade protrudes,

and vice versa.

Draw up the arresting nut after setting

up the required scoring blade position.

Max. height of blade jags over-

reaching must not exceed 3mm !

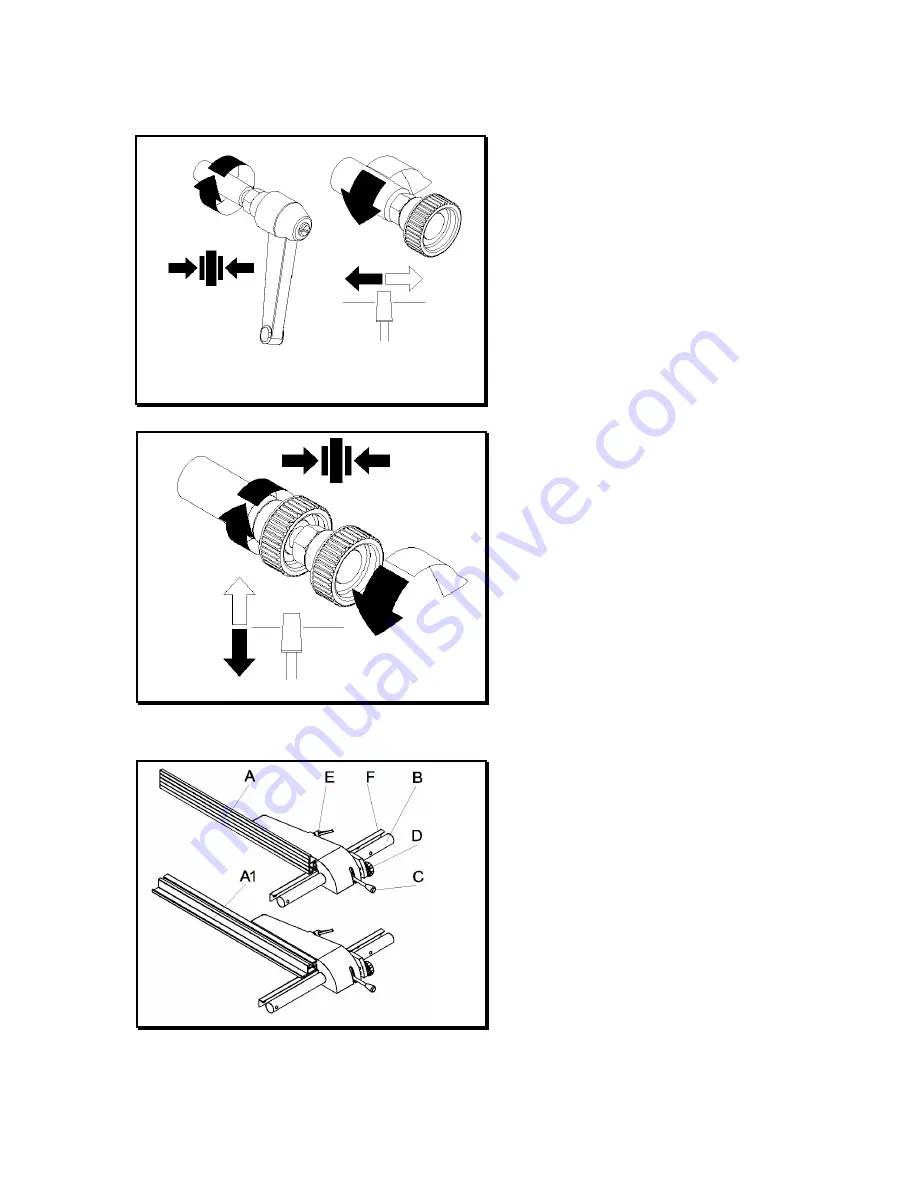

9.5 Adjusting of lengthwise ruler

Required sawing width gets adjusted

by shifting of lengthwise ruler (A) along

the leading bar (B). The position is

locked with the safety lever (C). For a

more accurate setting it is possible to

use fine sliding by help of a screw with

a star. The ruler (A) – after releasing of

arresting screws (E) – can be

protruded and the “L“ profile can be

turned into position (A1) when sawing

narrow pieces. Sawing width is

showed at the measure. The carrying

profile can be moved to sides after

releasing of fixing screws.

The measure can be so adjusted onto

the correct value considering to the set

of saw jags of used saw blade.