When connecting the Power Supply Module do

NOT

make any connection to the

AUX (RED)

terminal from the Main

Panel. It is used for the outgoing BUS to supply voltage to other modules. The module supplies power to all modules

and/or keypads located AFTER the point that it is connected to the BUS.

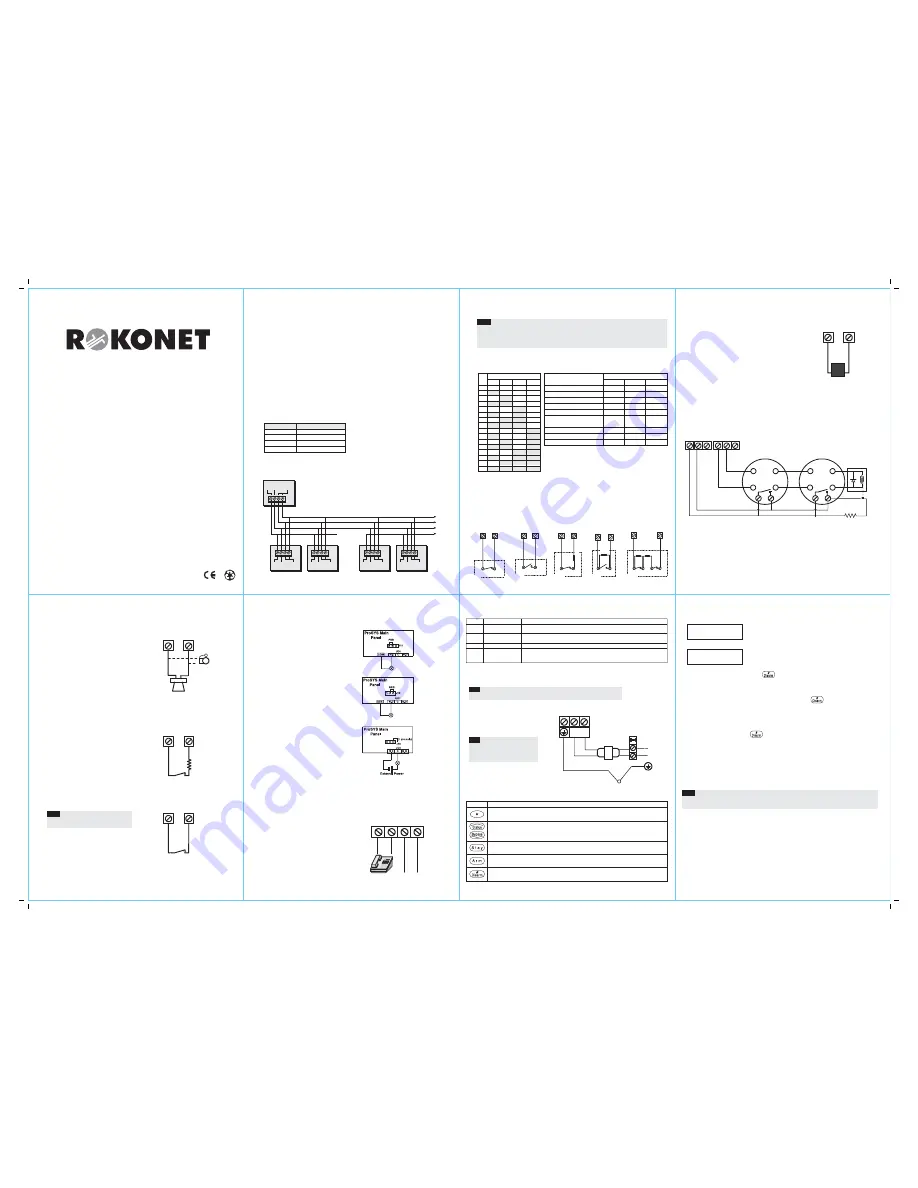

B: Defining Modules ID number

Each accessory has its ID category number, which is defined by dipswitches. ID numbers are defined per category

and the first module in each category is defined as ID=1. Before setting power on, define each module’s ID number

by setting the dipswitches as follows:

2. Zone Inputs Connection

To connect a hardwired zone use a 4-conductor cable

wiring.

Connect each zone to the appropriate Zone (Z) terminal and its related COM terminal. Each pair of zones shares a

COM terminal. It is recommended that you use an End-of-Line Resistor at the far end of each hardwired zone to prevent

short-circuits (16 resistors are supplied). For a zone with a tamper switch, you can use a Double End-of-Line Resistor

to save additional Main Panel connections

Zone Terminations

ProSYS / WaveSYS*

QUICK START

INSTRUCTIONS GUIDE

(For full comprehensive instructions refer

to the ProSYS Installer Manual 5IN128IM)

PROSYS MAIN PANEL

AUX

COM

Auxiliary device as: PIR,Glass

break detector , Audio switch ...

BELL/LS

+

-

PROSYS MAIN PANEL

BELL

LOUDSPEAKER

(13.8 v, 900 mA MAX)

BOX

TMP

COM

BOX TAMPER

(N.C)

TYPICAL FIRE ZONE WIRING

(Two 4 wire smoke detectors)

+IN

-IN

+OUT

-OUT

+IN

-IN

+OUT

-OUT

AUX

UO

COM

Z

2.2 K EOL RESISTOR

ALRM

CONTACT

ALRM

CONTACT

PROSYS MAIN PANEL

END OF LINE ZONE

(N.O CONTACT)

zone

com

ALARM

2.2

K

DETECTOR

NORMALLY OPEN ZONE

CONFIGURATION

ALARM

zone

com

DETECTOR

NORMALLY CLOSED

ZONE CONFIGURATION

ALARM

zone

com

DETECTOR

END OF LINE ZONE

(N.C CONTACT)

2.2

K

zone

com

ALARM

DETECTOR

DOUBLE END OF LINE

ZONE CONFIGURATION

com

2.2

K

ALARM

TAMPER

zone

2.2

K

DETECTOR

RING

TIP

LINE

SET

T

R

TO TELEPHONE

LINE

PROSYS MAIN PANEL

BELL TAMPER

BELL

TMP

COM

2.2 K EOL

RESISTOR

R O K O N E T

P l e a s e W a i t . . .

T o I n s t a l l

P r e s s

*

Introduction

ProSYS is a modular integrated system that combines access control, security protection, and home automation, with the

advantage of controlling the whole system through one interface.

ProSYS is available in three models that use the same accessories, but have different maximum capabilities (ProSYS 128,

ProSYS 40, ProSYS 16) . Through its 4-wire BUS, it can support a variety of optional modules, including multiple Keypads,

Zone Expanders, a Wireless Interface, supplemental Power Supplies, a Voice module, capabilities for Access Control, an

X-10 Interface, Event Log, and Utility Outputs. All these devices communicate with the system by sending commands and

data over the BUS, which originates at the Main Panel.

We recommend reading and fully understanding the ProSYS Installation manual and User’s manual before any installation

of the system is carried out. The Quick Start Instructions guide is intended for those who have experience in installing Rokonet

security panels. For additional information refer to the ProSYS Installer Manual (p/n 5IN128IM).

STEP 1: Mounting the Main Panel

Consideration in locating the fixing of the main panel should be given to:

●

Dry place near an AC power supply (switched off).

●

With a good earth connection.

●

With access to the customer's phone lines.

●

Access for the routing of cables for the system from detection devices.

STEP 2: Wiring the Main Panel

1. BUS Connection

A: Wiring External Modules

The set of four terminals on the left of the Main Panel represents the Expansion BUS. These support the connection

of keypads and expansion modules. The connections are terminal-to-terminal with color-coded wires, as follows:

BUS Terminal

Description

AUX RED

+12V power

COM BLK

Black 0V common

BUS YEL

Yellow DATA

BUS GRN

Green DATA

The parallel wiring system supports parallel connections from any point along the wiring. The maximum wire run

permitted is 300 meters (1000 feet) for all legs of the BUS. To prevent a possible drop in voltage due to multiple

keypads and long wire runs, use a quality 4-conductor cable with an appropriate gauge size.

3. Wiring Auxiliary Devices

The main panel has 2 aux terminals. Use the

Auxiliary Power

AUX (+) COM (-)

terminals to power PIRs, glass-break detectors

(4-wire types), smoke detectors, audio switches, photoelectric

systems and/or any device that requires a 12V DC power supply.

The total power from the

AUX

terminals should not exceed

600mA.

If the auxiliary outputs are overloaded (exceed 600mA) and

are shut down, you must disconnect all loads from the outputs

for a period of at least 10 seconds before you reconnect any

load to the auxiliary outputs.

4.

Bell Sounder Wiring

The

Bell/LS

terminal determines the output for the bell

or external sounder. When connecting the internal

sounding device pay attention to the polarity.

To avoid Bell Loop Trouble, if

NO

connection is made

to an internal sounder, use a 2.2K

Ω

resistor in its place.

It is important to position the

BELL/LS Jumper (J3)

correctly. The position varies depending on the type

of internal sounder.

A maximum of 900 mA may be

drawn from this terminal.

5. Bell Tamper Wiring

Connect the bell tamper to the

BELL TMP

and

COM

terminals on the Main Panel, as illustrated.

6. Box Tamper Wiring

Connect the box tamper to the

BOX TMP

and

COM

terminals on the Main Panel, as illustrated.

Note:

The Box Tamper input provides double protection,

wall and box.

7. Utility Output Wiring

UO1: Relay output

(3 Amps). Usually used for an external

siren connection. Use the J10 jumper located on the main

board to determine the UO1 (behaviour) as follows:

Positive (POS)

: When the J10 connector is placed on POS,

the C terminal on UO1 supplies 13.8V.

Negative (NEG)

: When the J10 connector is placed on

NEG

,

the C terminal on UO1 supplies COM.

Single pin

: If the J10 connector is placed

only on 1 pin

, the

UO1 acts as a dry contact.

UO2-UO6:

Transistor outputs (UO2 — 500 mA, UO3-UO6 70 mA). Connect the positive connection of the device to

AUX

(+)

and the negative

(-)

connection to the UO's terminals.

8. Telephone Line Connection

Connect the incoming telephone line to the Main

Panel's

LINE

terminals.

Connect any telephone on the premises to the

SET

terminals.

9. Setting Jumpers

Use the following table to position the jumpers located on the ProSYS main board

Jumper Jumper Description Jumper Operation

J2

Default jumper

For regular operation position the default jumper over one of the J2

connector pins for safekeeping. To default the system position the jumper over the 2 pins

J3

Bell/Loudspeaker

Set this jumper according to the type of siren connected to the system

(bell or loudspeaker)

J4

SIG IN

Connect to the voice module p/n RP200VC

J6 Voice

Connector

This connector transmits signals from the Advanced Digital Voice module to the telephone

line during remote communication, and is essential for normal operation of the Digital

Voice module.

10. Ground Connection

Connect the metal box and the door of the metal box to main earth (ground).

Note:

Connecting to ground must be performed according to the local National Electrical Code.

11.Main Power Connection

Connect the 230V AC to the mains fuse

input terminal block (N,L). Fasten the AC

cord to the metal box using adjustable

clamps.

Note:

Be sure to connect the live wire of the AC

power through the AC fuse. The size of

the conductors must not be less than

0.75mm

2

(18AWG).

STEP 3: Installer Programming

The ProSYS can be programmed from local or remote Upload/Download software or from the LCD Keypad used as an

interface tool. The following keys are used in the programming procedure. For additional information refer to the Installer

manual.

Key

Programming Mode Function

Use this key to exit the current programming selection and move up to the next higher level in the programming

hierarchy catalog.

Press either one of these keys to move back and forth through the programming level functions.

These keys also change the position of the flashing cursor. When editing a selection, the cursor moves to

the left or right respectively.

Use this key to toggle forward through the programming

choices within a selection.

Use this key to toggle backward through the programming

choices within a selection.

Use this key to enter selected information into the system or to accept the current selection and access the

lower level of options in the programming hierarchy.

◆

Initial Setting

1. When defaulting the panel (position J2 on both pins and then power on the system) you enter the installer Programming

menu and the Auto Install feature (Automatic Module recognition). The first display will be:

2. After a short delay the following display appears:

3. Press [*]. The keypad prompts you for the Installer code.

4. Enter the default Installer Code followed by

depending on the ProSYS Model:

●

ProSYS 128:

[0][1][2][8]

●

ProSYS 40:

[0][1][4][0]

●

ProSYS 16:

[0][1][1][6]

5. The system enters the automatic accessories recognition process. Press

to acknowledge each module.

6. To exit Installer programming press “0” from the Installer’s main menu.

7.

Position the J2 default jumper on one pin to save data.

◆

To access the Installer Programming Menu from the regular operation mode: (J2 is on one pin)

1. From the regular (user) operation mode press: [*][7][1]

2. The keypad prompts you for the Installer code.

3. Enter the Installer Code followed by

for accessing the Installer menu.

◆

Reset to default modes

To restore the Main Panel to the manufacturer's defaults

:

1. Disconnect all power from the Main Panel.

2. Position the J2 default jumper on both of the J2 pins.

3. Reconnect the power to the main and backup battery to the Main Panel. The keypad sounds a long beep and all

of the LEDs flash once. After 20 seconds the following message is displayed: “To Install Press *”

4. On the Main Panel, reposition the J2 default jumper on one of the J2 pins (where it resides for safekeeping).

5. Remember that the Installer Code has been restored to the manufacturer's default setting.

Note

:

To enable the restore of the manufacturer's default, the system bit "Default Enable/Disable" (defined in quick key

[1][7] in the main Installer menu) must be defined as Enable.

5IN128IMQ

ISRAEL

Rokonet Electronics, Ltd.

14 Hachoma st. 75655

Rishon Letzion

Tel: +972-3-961-6555

Fax: +972-3-961-6584

e-mail: info@rokonet.co.il

www.rokonet.com

USA

Rokonet Industries, Inc.

Tel: +1-305-592-3820

Fax: +1-305-592-3825

Toll Free: 1-800-344-2025

e-mail: sales@rokonetusa.com

UK

Rokonet U.K. Ltd.

Tel: +44-1527-576-765

Fax: +44-1527-576-816

Free Phone: 0800-269881

e-mail: info@rokonet.co.uk

ITALY

Rokonet Electronics SRL

Tel: +39-02-392-5354

Fax:: +39-02-392-5131

e-mail: info@rokonet.it

BRAZIL

Rokonet Brasil Ltda.

Tel: +55-21-2496.3544

Fax:: +55-21-2496.3547

e-mail:rokonet-brasil@uol.com.br

www.rokonet.com

page 2

page 3

page 4

page 5

page 6

page 7

page 8

R I S C O G R O U P

PROSYS MAIN PANEL

L

N

16.5 VAC

40 VA

FUSE

315 mA

A C

Notes:

In the ProSYS 16 and the ProSYS 40, there is only one BUS, which can be connected to the BUS 1 terminal block

or to one of the two BUS 1 plugs (J1 and J5).

In the ProSYS 128, there is also a BUS 2, which is separate from BUS 1. You can connect to the BUS 2 terminal

block or to the BUS 2 plug (J8). In addition, if one of the BUSes is shorted or there is any kind of problem that

interrupts the BUS data, the other one will continue to operate normally.

J1, J5, J8 are used as quick BUS connectors. Use the 4 pin BUS plugs for easy connection of the BUS Adapter Cable

(RP296EBA) or the Memory Transfer Card.

1

2

3

4

01 OFF

OFF

OFF

OFF

02

ON

OFF

OFF

OFF

03 OFF

ON

OFF

OFF

04

ON

ON

OFF

OFF

05 OFF

OFF

ON

OFF

06

ON

OFF

ON

OFF

07 OFF

ON

ON

OFF

08

ON

ON

ON

OFF

09 OFF

OFF

OFF

ON

10

ON

OFF

OFF

ON

11

OFF

ON

OFF

ON

12

ON

ON

OFF

ON

13 OFF

OFF

ON

ON

14

ON

OFF

ON

ON

15 OFF

ON

ON

ON

16

ON

ON

ON

ON

Dipswitches

ID

ProSYS 16 ProSYS 40 ProSYS 128

Zone Expanders (include wireless)

1

1-4

1-8

Keypads

1-8

1-12

1-16

Output Modules

1-2

1-4

1-8

Supervised Power Supply

1-8

1-8

1-8

Access Control Modules

1-2

1-4

1-8

Memory Expansion

-

ID=1

ID=1

(512 events) (512 or 999)

Digital Key Readers

1-16

1-16

1-16

Voice Module

1

1

1

Wireless Key Buttons

1

1-4

1-4

Category

Modules ID Range

* WaveSYS Installation & Programming Instructions in this document

are equivalent to ProSYS 40.

AUX

RED

COM

BLK

BUS

YEL GRN

AUX

RED

COM

BLK

BUS

YEL GRN

AUX

RED

COM

BLK

BUS

YEL GRN

AUX

RED

COM

BLK

BUS

YEL GRN

Control Panel

Bus Connectors

Expansion Module

Bus Connectors

Expansion Module

Bus Connectors

Power Supply

Bus Connectors

Expansion Module

Bus Connectors

BREAK +12V AT

INPUT TO EACH

POWER SUPPLY

(KEEP 0V COMMON)

DATA

DATA

0V

+12V

DATA

DATA

0V

+12V

AUX

RED

COM

BLK

BUS

YEL GRN

X