49

The desk stops

and reverse during

operation.

Make sure that

nothing is blocking

the table movement.

Remove the obstacle.

If the problem

remains replace the

whole underframe.

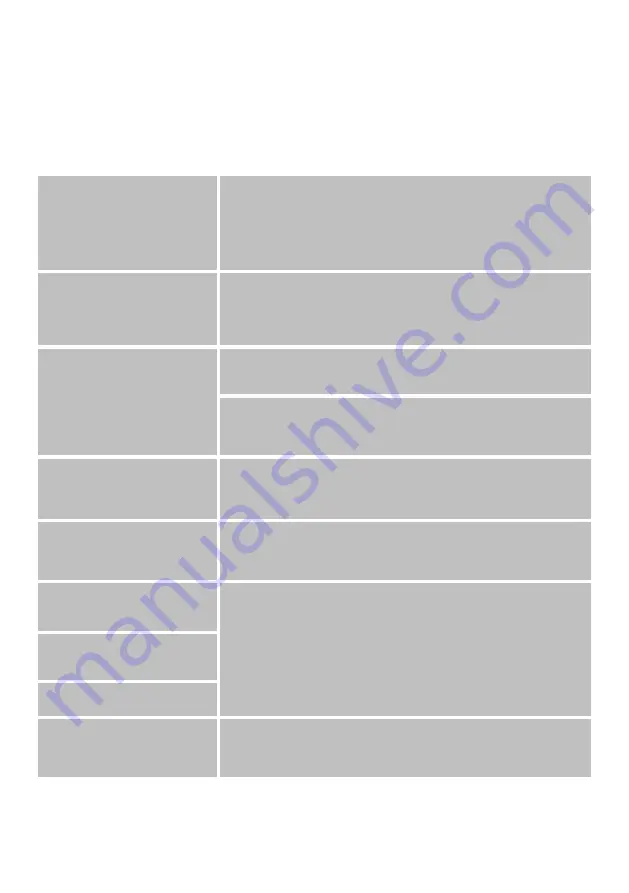

Problem

Suggested correction

Only one column is

moving.

Perform a reset. If

there’s still only one

column moving,

replace the column

that is moving.

The desk is not able

to move.

Unplug the desk from

the wall socket for

roughly one minute

and reconnect.

Make sure that all

cabels are connected.

Connect the cables.

Follow install

instructions and

perform a reset.

The desk only moves

short distances.

Make sure that

the desk is not

overloaded.

Unload the desk. If

the problem remains

replace the ECS box.

The desk is not able

to drive all the way up

or all the way down.

Peform a reset.

The desk can only

drive in one direction

(up or down).

The desk is not

horizontal.

680

1106

1-

A © ROL ERGO

Both columns are

moving but at

diff erent speeds.

It is possible to move

the slower column by

pulling/pushing.

It is not possible to

move the slower

column by pulling/

pushing.

Replace the column

that is moving faster

than the other.

Replace the column

that is moving slower

than the other.

During reset, only

one column is moving

downwards.

Motor or actuator

damaged. Change

the column that is not

moving.

6.3 Troubleshooting

Summary of Contents for ECS+ Series

Page 1: ...USER MANUAL Series EE ECS Work 1 Colab...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 12: ...12...

Page 22: ...22 2 Sliding table top 2 columns M8 25 8 Plastic plug 12 M8x16 x4 M8x16 x4 Cover for screw x4...

Page 36: ...36 M8 25 4...