- 9 -

MAINTENANCE

Your new air compressor represents the finest engineering and construction available. Even the best

machinery requires periodic maintenance. Please stick to the maintenance schedule and consider the suggestions

that follow to keep your compressor in peak condition.

NOTE: Always unplug or shut down your compressor and drain the air tanks completely before attempting any

type of maintenance. Wait for compressor to cool before servicing.

IMPORTANT: Replace the oil after the first 50 hours of operation.

MAINTENANCE HINTS:

1) Use a soap/water solution to check for air leaks.

2) Never clean filters with a flammable solvent.

3) Retorque head bolts only after pump has cooled.

4) Move motor 1/4" and roll belts back on to increase

belt tension on electric units.

5) Never weld on air tank(s).

6) Use heat to loosen Loctite seal on drain valves, engine

pulleys, and flywheels before attempting to remove.

OIL TYPE TABLE

Temperature

0-40°

40° & Above

NON-DETERGENT – Straight Weight

10WT*

30WT*

*For maximum performance and service life, we recommend using ROLAIR Premium Quality compressor oil.

MAINTENANCE SCHEDULE

Recommendation Daily

Weekly

Monthly

Quarterly

Check Oil Level

X

Drain Moisture from Tank(s)

X

Inspect Air Filter(s)

X

Check for Unusual Noise or Vibration

X

Inspect Belt Guard

X

Check for Air or Oil Leaks

X

Clean Exterior of Air Compressor

X

Check Condition of Vibration Pads

X

Tighten/Retorque Bolts

X

Check Belt Tension

X

Check Operation of Safety Valve

X

Change Compressor Oil

X

Clean/Change Air Filter

X

Perform Pump Up Time Test

X

Check Operation of System Controls

X

Check Air Tanks for Dents/Leaks

X

LUBRICATION

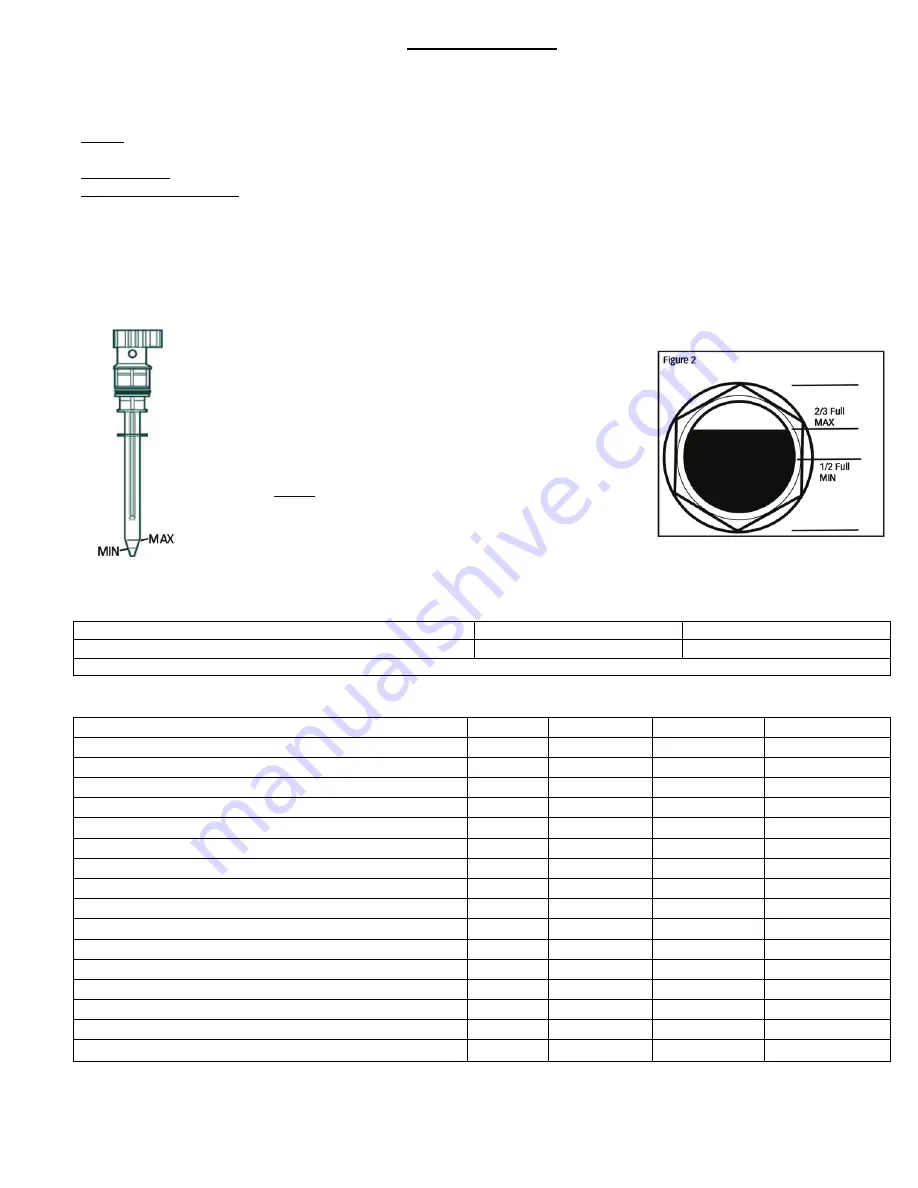

Prior to each use, make a habit of checking the pump oil

level. Most direct-drive air compressors have a dipstick with

casting marks that indicate the minimum and maximum

acceptable levels of oil. Our belt-driven pumps have a sight gauge,

located on the outside of the crankcase, to make the task even

easier. Always maintain the oil level at the maximum mark on the

dipstick or to 2/3 full in the sight gauge

Do not operate the pump with an inadequate or excessive

amount of oil. The cost of failures which occur due to incorrect oil

levels will not be covered under warranty.

DO NOT USE A DETERGENT OIL!

NOTE: Unit must be level when in operation