- 11 -

TROUBLESHOOTING

WARNING

-

Make sure you completely understand all of the safety warnings and operation of each system

control component before attempting any maintenance or repair. Always drain the tank pressure completely, make

sure the power cord is unplugged, and unit has time to cool before performing any maintenance or service

operations.

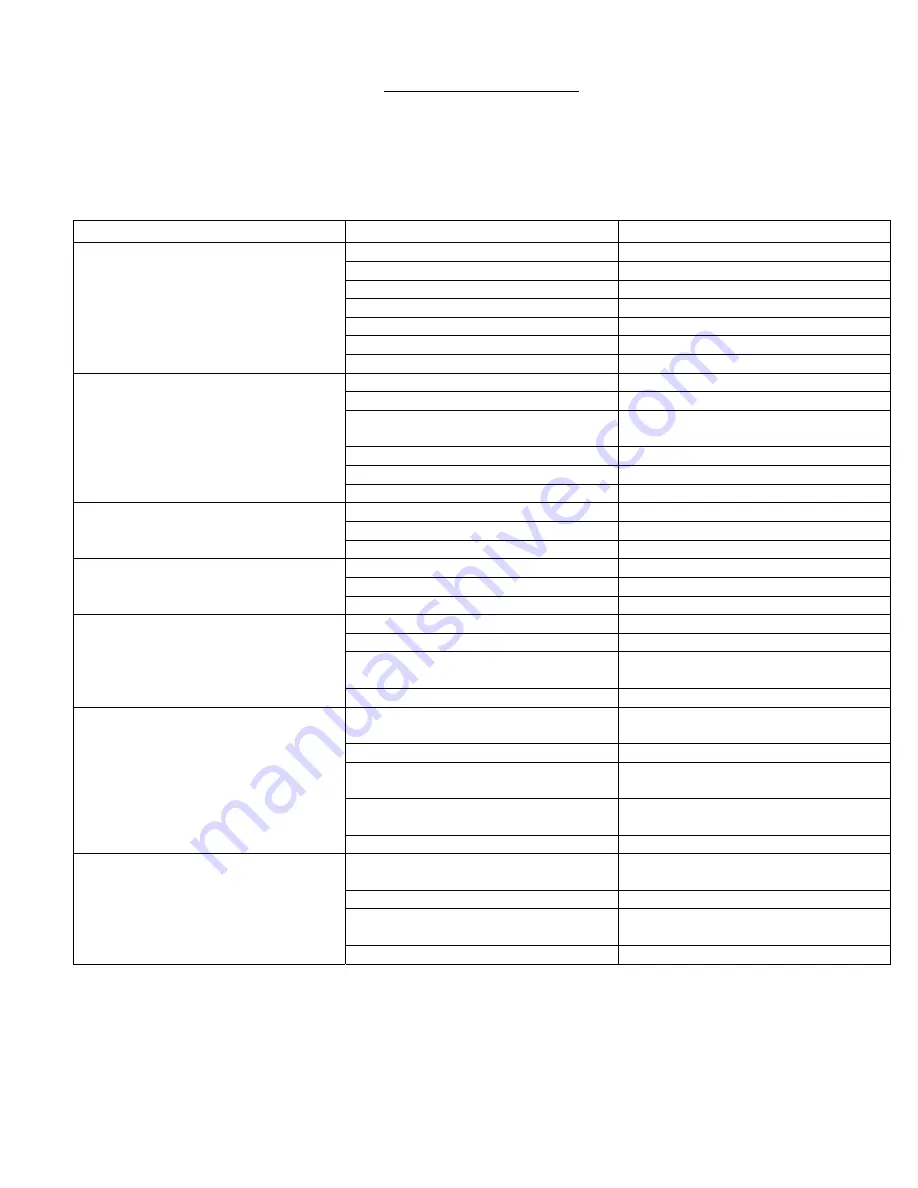

PROBLEM

CAUSE

SOLUTION

Pump is slow to build tank pressure

Loose/slipping belt

Adjust belt tension

Excessive leaks in system

Correct air leaks

Blown gasket

Replace head gaskets

Broken reed valve

Replace reed valves

Obstructed intake filter

Clean or replace intake element

Leaking regulator

Replace regulator

Defective pilot valve

Replace pilot valve

Excessive oil consumption

Too much oil in crankcase

Drain to proper level

Improper weight of oil

Replace with proper oil

Obstructed crankcase vent

Replace dipstick or oil fill

plug/crankcase vent

Dirty/plugged intake filter

Clean/replace intake filter

Worn piston rings

Take unit in for service

Scored cylinder

Take unit in for service

Knocking noise

Loose pulley or flywheel

Tighten appropriate parts

Loose belts

Adjust belt tension

Internal pump problem

Take unit in for service

Overheating compressor

Poor ventilation

Relocate compressor

Improper pump rotation

Contact an electrician

Internal pump problem

Take unit in for service

Electric motor dead,

will not even hum

Thermal overload tripped

Locate and push reset button

Reset physically broken

Replace overload/reset

Loose motor leads or electrical

connection

Locate and correct loose electrical

connection(s)

Short in power cord

Replace power cord

Motor trips overload/reset button

Motor is starting/stopping

excessively

Install constant speed or dual control

kit

Overload is defective/weak

Replace overload

Improper gauge of extension cord

Use longer lengths of air hose or

heavier cord

Stripped or poorly tightened motor

thru bolts

Retighten or replace stripped thru

bolts

Cracks in end bell or housing

Take unit in for service

Gasoline engine is hard to start

Fouled, incorrect, or improperly

gapped spark plug

Install proper spark plug after

gapping to factory specs

Improper engine oil level

Fill to top of threads for oil plug

Improper weight of pump or engine

oil

Change to proper weight of oil for

operating temperature

Improper or old gas

Take unit in for service