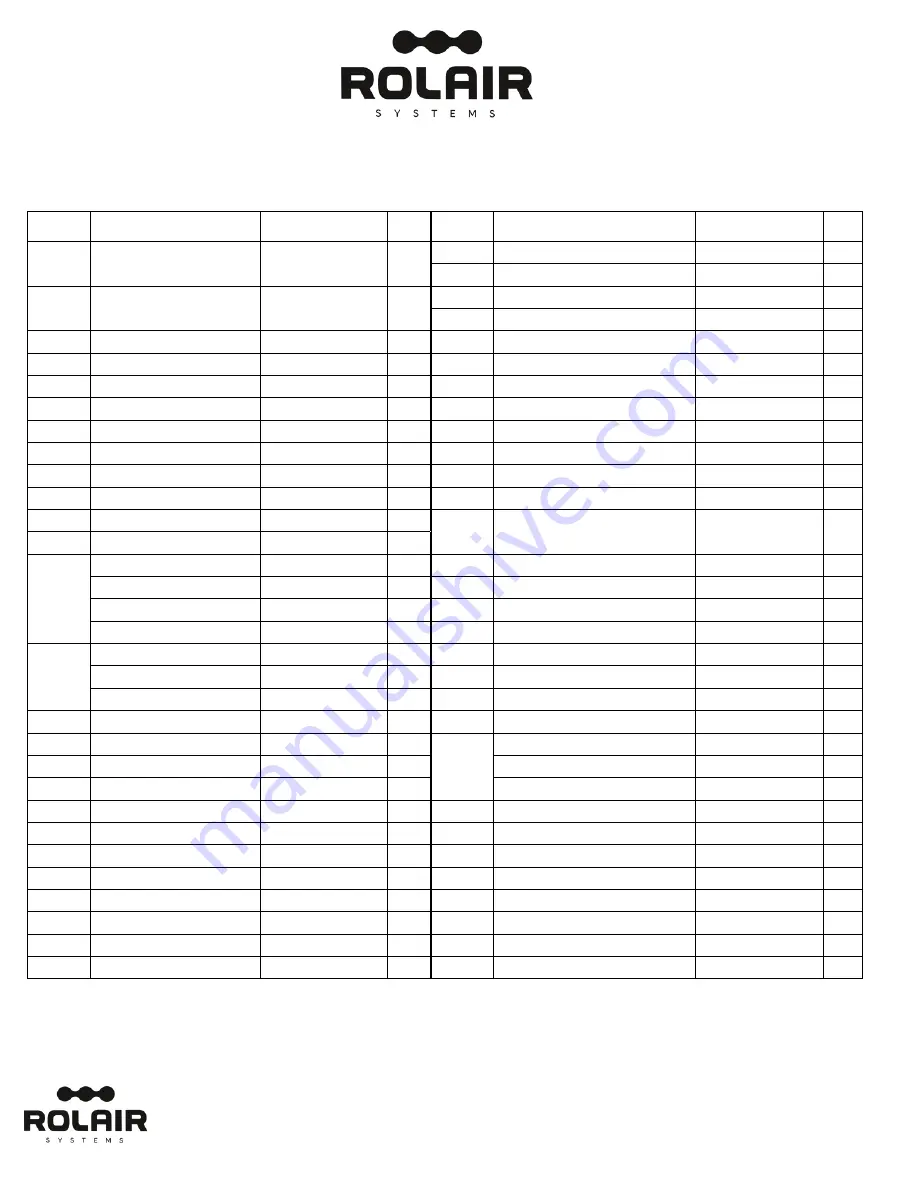

8/11

Schem

#

Description Part

#

Qty.

Schem

#

Description Part

#

Qty.

1

Twin Cylinder Pump with

Flywheel

PMP12K17CH 1

24 Drain

Valve

132BV

2

25

Twin Tank Assembly

TNKASY4090K17

1

Twin Cylinder Pump less

Flywheel

PMP12K17CHLF 1

26 Rubber

Foot

219

4

27 Cotter

Pin

181A

2

2A Gasket

30501490CH

1 28 Axle

181

1

2B O-Ring

30502510CH

1 29 Fully-Pneumatic Tire with Sealant

WLS30SEAL

1

3A Aftercooler

32901460CH

1 30 Pulley

PUAK44X0750

1

3B

Aftercooler - O-Ring Style

Use 3290146ACH

1

31

Belt Guard Cover

BG9145

1

4

Brass Elbow

145D

1

32

Belt Guard Base

BG9140B

1

5

Braided Discharge Tube

145F

1

33

Belt

BT4L510

1

6 Drain

Valve

132

1 34 Flywheel

31007280CH

1

7

Check Valve

CV4X4TA

1

35

Silencer/Filter Assembly

FS14050

1

8 Brass

Elbow

BREL0250X0125H16

2

Filter Element – Replacement for

Above

431 1

9 Hose

Clamp

177

2

10

1/4” Nylon Tube – 14.4”

178D

1.2’

36

Honda Engine

ENG05HO1

1

Brass Nut

BRNT0250

2

37

Brass Elbow

BREL0250X012539

1

Brass Sleeve

BRSL0250

2

38

Throttle Control Kit

192EGX160K1QX

1

Brass

Ring

BRRG0250

2 39

Gauge

GA0250200GC

1

11 Pilot

Unloader

Valve

131B

1 42 Belt

Tightener/Mounting Kit

SBT5HP-ANGLE*

1

Felt

Muffler

131BM

1 43

Screw

MIS10008

4

Retainer

Ring

131BR

1 44

Bolt

37302530CH

2

12 Nipple

BLNP0250X1500

1 45 Bolt

MIS10094

5

13 Aluminum

Block

Manifold 154

1 46 Bolt

MIS10022

2

14

Safety Relief Valve

SRV0250N165

1

Lock Washer

MIS10099

2

15 Nipple

BLNP0500X1500

1

Washer

MIS10108

2

16 Quick

Disconnect

309A

1

(Accessories)

17 Accessory

Bracket

210

1 47 Lubricator

LUB0375

1

18 Brass

Coupler

BRCP0375X0375H12

2 48 Regulator

REG0375

1

19

Hose Clamp

177A

2

49

Filter (Water Trap)

FIL0375

1

20

3/8” Rubber Hose – 16”

178A

1.34’ 50 Accessory

Bracket

210

1

21 Cap

BLCA0250

1 51 Nipple

BLNP0375X1500

3

22

1/4” Rubber Hose – 36”

178

3’

52 Brass

Coupler

BRCP0375X0375H12

1

23 Handle

Grip

328

2 53 Gauge

GA0250200GC

1

*For units built prior to February 2005, order SBT5HP-SQUARE.

PARTS LIST FOR MODEL 4090HK17

606 South Lake Street > P.O. Box 346 > Hustisford, WI 53034-0346 > 920.349.3281 > fax 920.349.3691 > www.rolair.com