*For maximum performance and service life, we recommend using ROLAIR Premium

Quality Air Compressor Oil

3.

The warranty on the motor will be NULL and VOID if a failure occurs and

inspection proves a current deficiency.

4. The PRESSURE SWITCH and/or pilot unloader valve are set at factory for

maximum efficiency. DO NOT alter setting. Adjusting either will VOID

the warranty.

5.

Engine RMP’s (High – Low Settings) are factory set for maximum

efficiency. Adjusting RPM’s above factory specifications voids warranty.

6. ALWAYS shut off the engine’s fuel line before transporting a gas

powered air compressor. If left open, gas will seep past the needle/seat

in carburetor, mix with the oil in the engine’s crankcase, and foul out

the spark plug. Replacement of spark plug and oil change will not be

covered under warranty.

PLEASE NOTE: Refer to the enclosed engine owner’s manual for

additional operating information

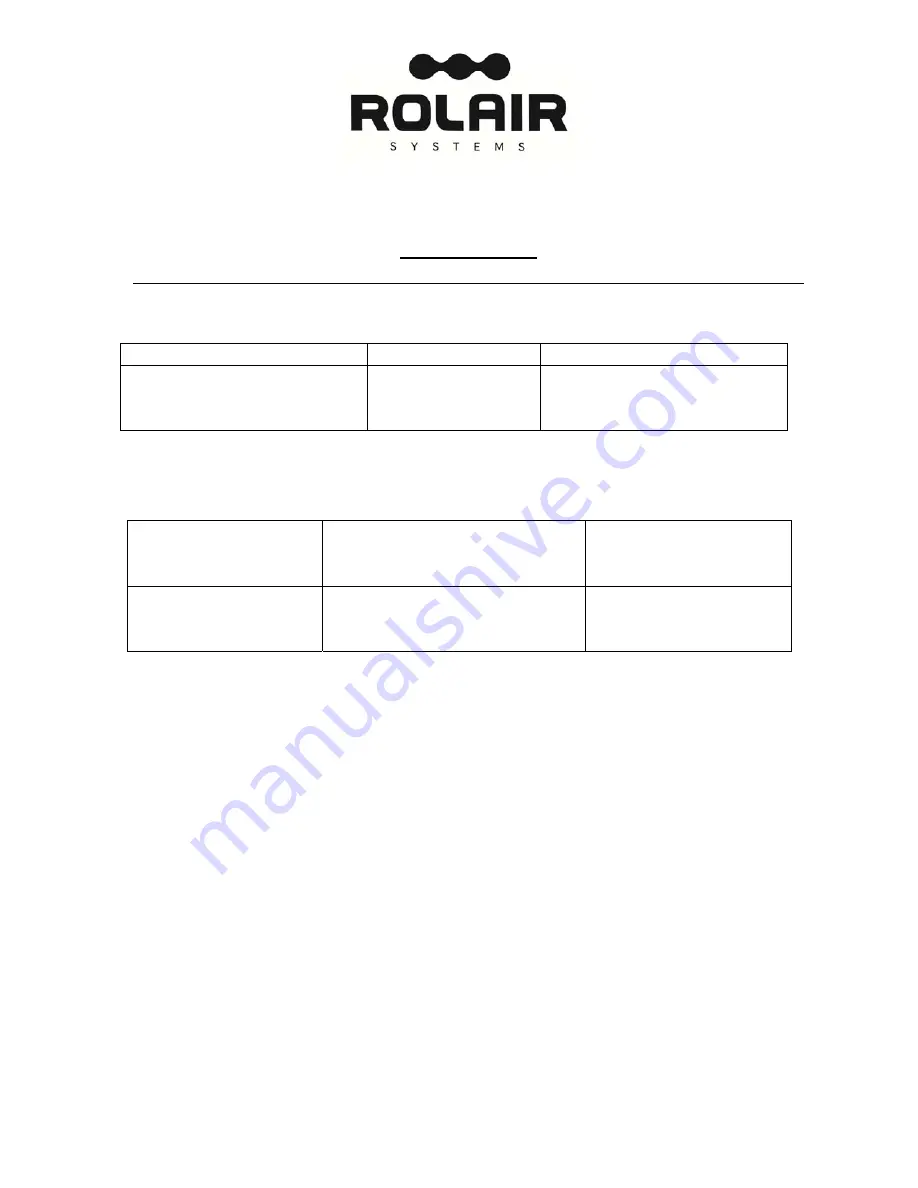

Temp.

0 - 40°

40° & above

NON-DETERGENT

Straight Weight

Recommended

10 WT

30 WT

Extension Cord

Length

Motor

1/2 and 3/4 HP

Minimum Wire Size

Motor

1, 1-1/2 and 2 HP

Minimum Wire Size

Up to 25 Ft.

14 Ga.

12 Ga.

25-50 Ft.

12 Ga.

10 Ga.

50-100 Ft.

10 Ga.

8 Ga.

SPECIFICATIONS & GUIDELINES

*IMPORTANT:

READ ENCLOSED MANUALS BEFORE OPERATING YOUR COMPRESSOR

1. OIL TYPE TABLE

2. EXTENSION CORD TABLE