- 6 -

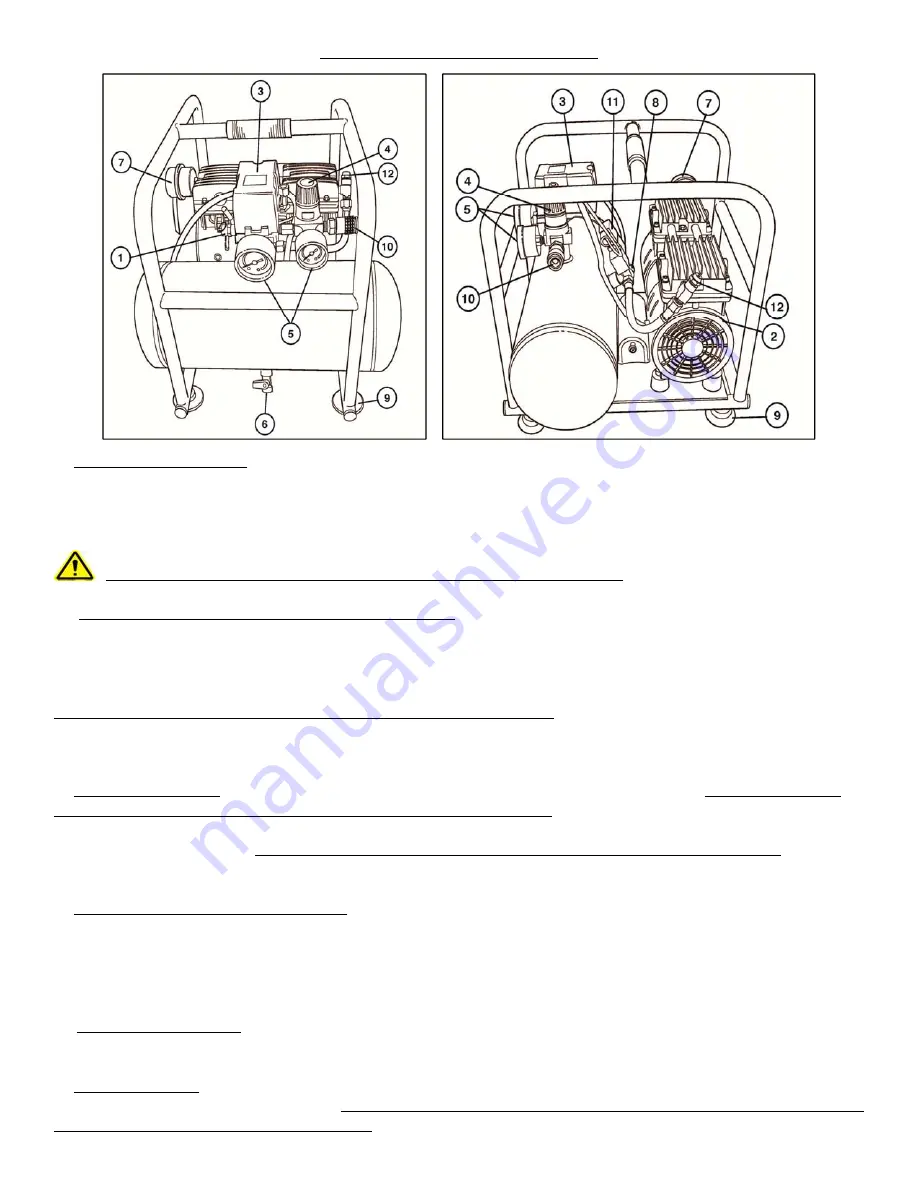

SYSTEM CONTROLS

1. SAFETY-RELIEF VALVE Every ROLAIR

®

air compressor is equipped with a safety-relief valve which is

designed to discharge tank pressure at a predetermined setting when a systems failure occurs. Check the

safety valve periodically by pulling on the ring only after the tank pressure has been completely drained. The

spring loaded valve should move freely within the safety valve body. An inoperable safety valve could allow

an excessive amount of tank pressure to build causing the air tank to catastrophically rupture or explode.

Do not tamper with or attempt to eliminate the safety relief valve.

2. AUTOMATIC INTERNAL OVERLOAD PROTECTION The JC series motor is built with automatic overload

protection. When an electrical deficiency occurs, the overload will interrupt the power supply and

automatically shut down the motor to protect it. When the overload sufficiently cools, the motor will

attempt to restart automatically. If the electrical deficiency that caused the overload to trip is not corrected,

the motor will continue to overheat and restart which may lead to a complete motor failure. Therefore,

NEVER LEAVE THE AIR COMPRESSOR PLUGGED IN UNATTENDED. Always re-evaluate the power source

and gauge/length of extension cord being used whenever the overload causes the motor to stop running.

(Refer to the chart on page 8.)

3. PRESSURE SWITCH Your air compressor operates by the use of a pressure switch. Always make sure

the lever is in the “Off” position before plugging in the power cord. By moving the lever to the “On/Auto”

position, the compressor will start and stop automatically within the settings of the pressure switch which

are typically 95 - 125 PSI. Do not attempt to stop the compressor by unplugging the power cord. To stop,

simply move the lever to the “Off” position.

4. REGULATOR – WORKING PRESSURE To adjust the output/line pressure, simply rotate the regulator

adjustment knob clockwise to increase working pressure or counterclockwise to decrease. Never exceed

the manufacturer’s maximum allowable pressure rating of the tool being used or item being inflated.

Always relieve pressure from coupler by rotating adjustment knob completely counter-clockwise before

removing air hose.

5. PRESSURE GAUGE(S) Typically, most compressors are designed with a gauge to measure tank or

storage pressure and another gauge that indicates output or working pressure.

6. DRAIN VALVE(S) One or more drain valves are installed to allow moisture to be drained on a daily basis

from the compressor storage tank(s). Open drains carefully and slowly to prevent scale, rust, or debris from

becoming expelled at a high rate of speed.

Summary of Contents for JC10

Page 12: ... 12 ...

Page 14: ... 14 ...