- 8 -

PRE-START CHECKLIST (continued)

3.

INSPECT/CLEAN/CHANGE INTAKE ELEMENTS ON A REGULAR BASIS

The ingestion of dirt into the pump and engine is the primary cause of premature wear. Pay special

attention to the intake filters. Check intake filters daily.

4.

USE LONGER PROPERLY SIZED AIR HOSE RATHER THAN EXTENSION CORDS

If an extension cord must be used, please refer to the chart on the following page for the proper gauge

and maximum length that can be used. The use of inadequately sized air hose will also lead to frictional

pressure drops that could affect the proper performance of your air tools.

5.

DO NOT USE A GENERATOR AS THE POWER SOURCE

Air compressors use inductive motors that require 3-5 times the full-load amp draw to properly start.

Most generators will not provide the wattage needed to properly start this type of electric motor.

6.

CHECK TENSION OF BOLTS, BELTS, AND HARDWARE ON A REGULAR BASIS

Operation of any equipment with loose bolts and/or fittings will lead to excessive vibration

and the premature failure of the compressor system control components.

7.

MAINTAIN RUBBER VIBRATION PADS

Excessive vibration is a major cause of premature compressor failure. Always maintain the rubber

vibration pads located beneath tank assembly. Operation without them will void your warranty.

8.

DRAIN MOISTURE FROM AIR TANK DAILY

Water is a natural byproduct of compressed air. Drain air tank(s) after each use to combat internal tank

corrosion. Keep drain valve(s) closed if storing compressor for any length of time.

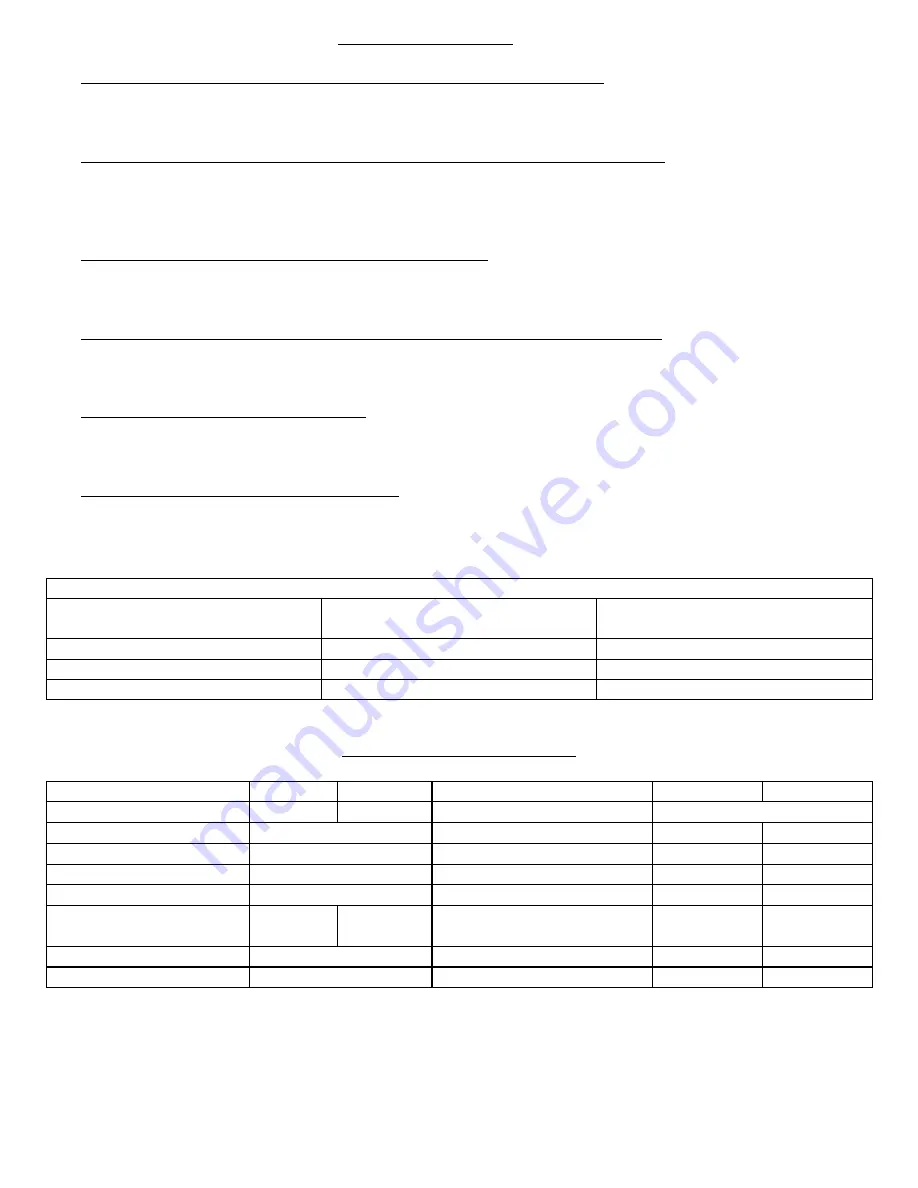

ELECTRIC EXTENSION CORD TABLE

Minimum Wire Size

Extension

Cord Length

Motor

1/2 and 3/4 HP

Motor

1, 1-1/2, and 2 HP

Up to 25 ft.

14 Ga.

12 Ga.

25 – 50 ft.

12 Ga.

10 Ga.

50 – 100 ft.

10 Ga.

8 Ga.

SPECIFICATIONS

JC13

JC10

JC13

JC10

Horsepower

.75

1.0

Tank Capacity

2.3 Gallon

Voltage

115 V

Pump-Up Time (0-125 PSI)

1:32

:56

Hertz

60 hZ

Recovery Time (95-125 PSI)

:47

:15

Motor RPM

1725

CFM Displacement

2.5

5.3

Stage(s)

Single

CFM Free Air @ 90 PSI

1.1

2.35

Amperage

(on 115 V @ 125 PSI

4.6A

8.0A

Dimensions (LxWxH – in.)

17x16x15

17x14x14

Thermal Protection

Automatic Weight

(lb.)

27

39

Factory Settings

95 – 125 PSI

Noise Level (dBA)

56

60

Summary of Contents for JC10

Page 12: ... 12 ...

Page 14: ... 14 ...