- 2 -

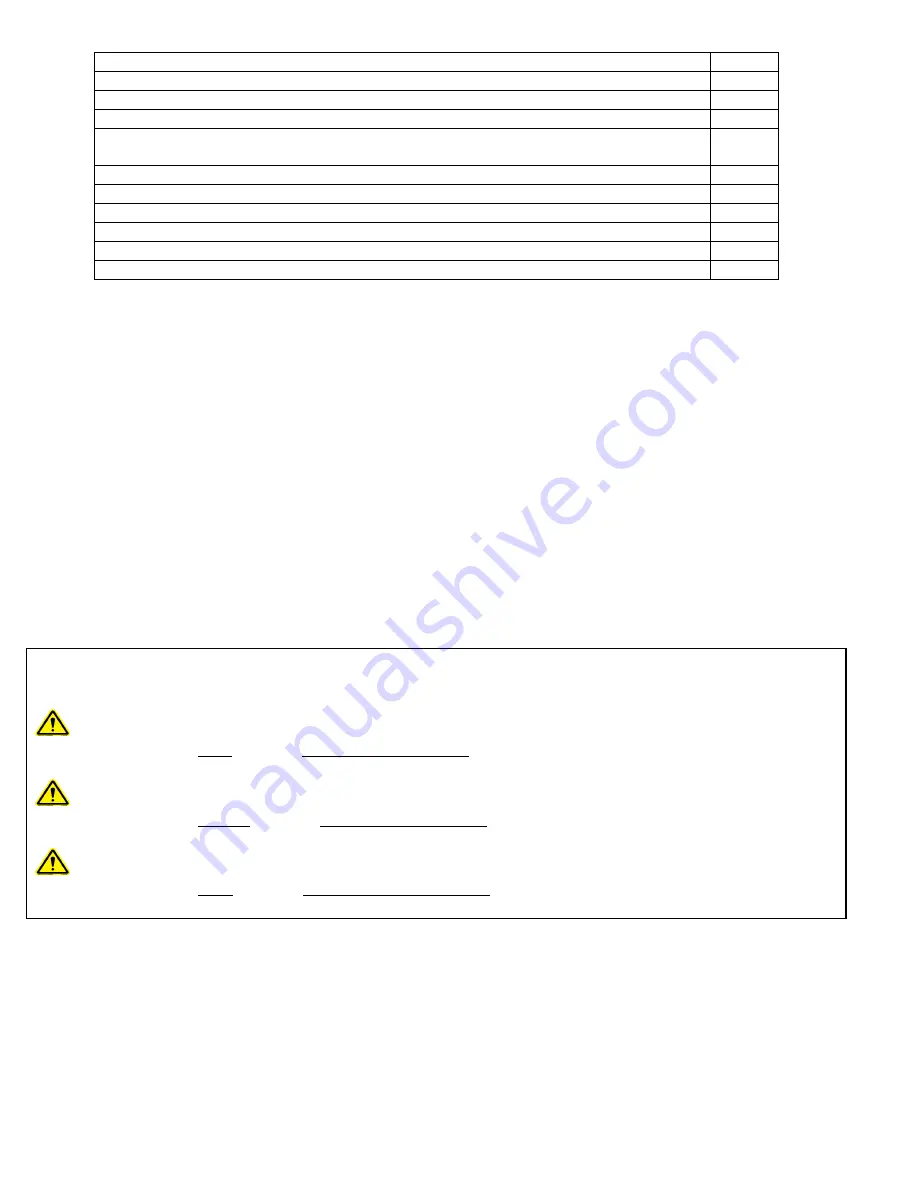

TABLE OF CONTENTS

Introduction and Definitions of Safety Warnings

2

Safety Warnings – Risk of Asphyxiation & Bursting

3

Safety Warnings – Risk of Electrocution, Shock, Explosion, & Fire

3

Safety Warnings – Risk of Moving Parts, Burns, & Lifting

4

Safety Warnings – Risk of Propelled Objects, Unsafe Operation, and Damage

To Compressor or Property

4

Identification of System Controls

5-6

Pre-Start Checklist

7

Operation

8-9

Maintenance

9-11

Troubleshooting

12

Guarantee

13

INTRODUCTION

Congratulations on the purchase of your new

ROLAIR

®

air compressor!

With over 50 years experience building

ROLAIR

®

air compressors specifically designed for the professional,

Associate Engineering Corporation has earned a reputation for providing a product unsurpassed in quality

and reliability. We are committed to continuing this tradition by analyzing and adapting to the changing

needs and rigorous demands of your industry. You can depend on

ROLAIR

®

because they are built to last.

This manual was compiled for the benefit of the operator. Do not use or allow anyone else to use your air

compressor until this manual is read and all safety/operating instructions are understood. By reading and

following the instructions contained in this manual, you can achieve years of trouble free service from your

new air compressor. If you have any additional safety or operating questions after reading this manual,

please contact your distributor or our customer service department. Do not remove or paint over any of

the warning decals attached to the compressor.

Definitions – Safety Warnings

Safety symbols are used throughout this manual to alert you to potentially hazardous situations. The

following definitions describe the level of severity for each signal word.

DANGER:

Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

WARNING:

Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

CAUTION:

Indicates a potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury or damage to the air

compressor.