22

Mar. 2008

GT-10

14. RETURN

Testing of the RETURN Circuitry and the RETURN

Jack Switch

fig.14return2.eps

1.

Using the two cables with 1/4-inch phone plugs, connect the

OUTPUT L

and

R

jacks to channel 1 and channel 2 of the oscilloscope and to the left-

channel and right-channel monitor speakers.

2.

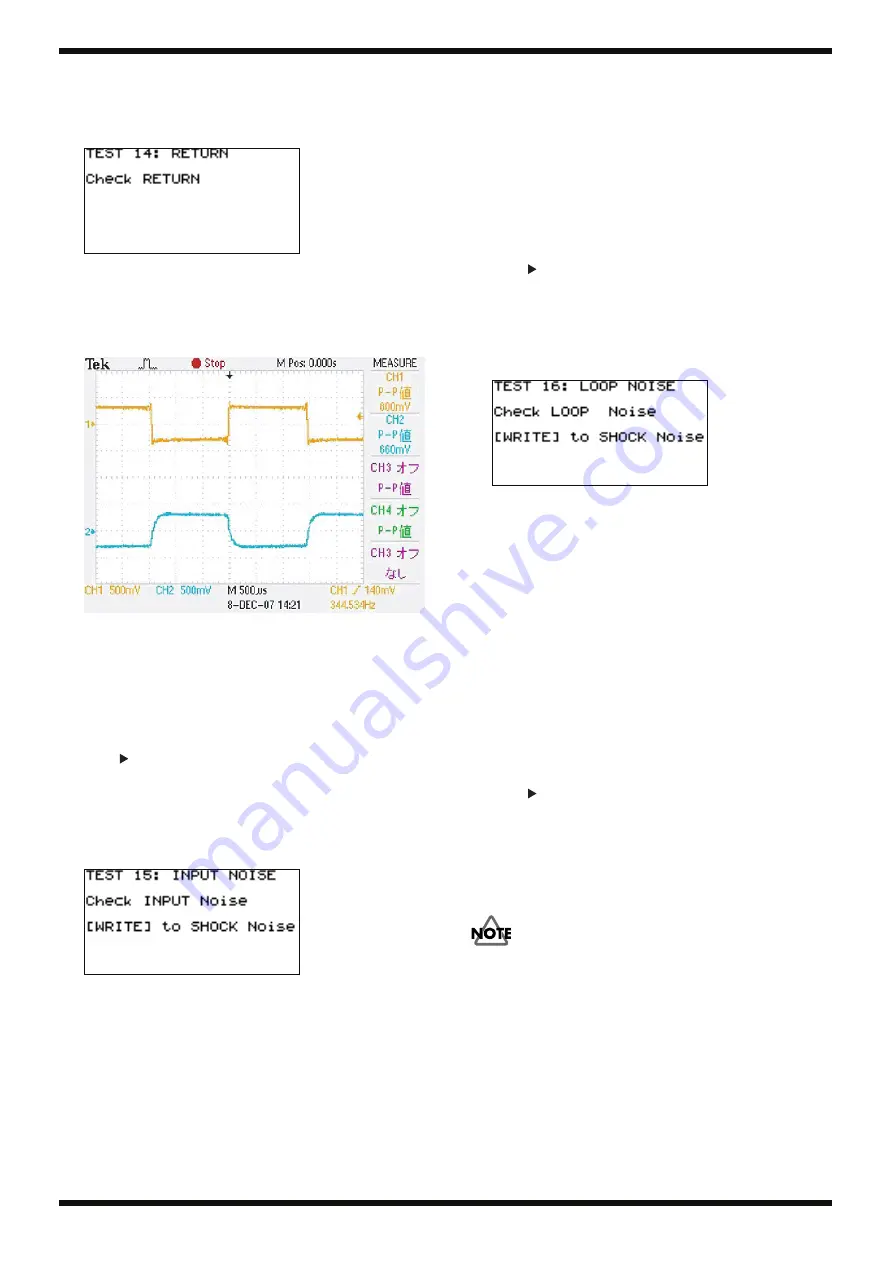

Verify that the output waveform display on the oscilloscope is what is

shown in the figure below.

fig.14return.eps

Upper: left channel, lower: right channel

3.

Verify that the peak value is from

0.75

to

0.90 V for the left channel and

from 0.60

to

0.70 V

for the right channel.

4.

Verify that signals are output from the monitor speakers and no noise or

other abnormal sound is heard.

5.

Insert a dummy jack (open plug) into the

RETURN

jack and verify that

the sound and waveform disappear.

6.

Press [

] to advance to the next test.

15. INPUT NOISE

Testing of Residual Noise and Shock at the

Respective Outputs

fig.15inputnoise2.eps

1.

Insert a 47-k ohm plug into the INPUT jack.

2.

Connect the left channel of the

PHONES

jack and the noise meter using a

cable with a 1/4-inch stereo phone plug (with 33-ohm load resistor), and

verify that the noise level is

-96 dBu

or less (

DIN audio

).

3.

Connect the right channel of the

PHONES

jack and the noise meter using

a cable with a 1/4-inch stereo phone plug (with 33-ohm load resistor),

and verify that the noise level is

-96 dBu

or less (

DIN audio

).

4.

Connect the

OUTPUT L

jack and the noise meter using a cable with a 1/4-

inch stereo phone plug, and verify that the noise level is

-89 dBu

or less

(

DIN audio

).

5.

Connect the

OUTPUT R

jack and the noise meter using a cable with a 1/

4-inch stereo phone plug, and verify that the noise level is

-89 dBu

or less

(

DIN audio

).

6.

Using the two cables with 1/4-inch phone plugs, connect the

OUTPUT L

and

R

jacks to the left- and right-channel monitor speakers.

7.

Press the [WRITE] button and verify that the

Check INPUT Noise

message displayed changes to

Check SHOCK Noise

.

8.

Verify that the noise sound played by the monitor speakers is free of any

problem.

9.

Subject the unit to vibration and verify that no abnormal sound is heard

from the speaker.

10.

Press [

] to advance to the next test.

16. LOOP NOISE

Testing of the SEND/RETURN Connection and

RETURN Shock

fig.16loopnoise2.eps

1.

Insert a 47-k ohm plug into the

INPUT

jack.

2.

Make sure that nothing is inserted into the

RETURN

jack.

3.

Connect the

OUTPUT L

jack and the noise meter using a cable with a 1/4-

inch phone plug, and verify that the noise level is

-88 dBu

or less (

DIN

audio

).

4.

Connect the

OUTPUT R

jack and the noise meter using a cable with a 1/

4-inch phone plug, and verify that the noise level is

-88 dBu

or less (

DIN

audio

).

5.

Using the two cables with 1/4-inch phone plugs, connect the

OUTPUT L

and

R

jacks to the left- and right-channel monitor speakers.

6.

Press the [WRITE] button and verify that the

Check LOOP Noise

message displayed changes to

Check SHOCK Noise

.

7.

Verify that the noise sound played by the monitor speakers is free of any

problem.

8.

Subject the unit to vibration and verify that no abnormal sound is heard

from the speakers.

9.

Press [

] to advance to the next test.

17. FACT RESET

Factory Reset

* Unless instructed otherwise, do not execute a Test Mode Factory Reset. Pressing

[EXIT] performs no Factory Reset.

Executing the Factory Reset in the Test Mode (

17. FACT RESET

) initializes the

threshold value for pedal calibration (to a value of

6

). When you have executed

17. FACT RESET

, go to

7. INT EXP PEDAL

and make the setting for pedal

calibration.

Short Check

Testing of AMP CTRL Insulation

1.

Switch off the power.

2.

Touch the tester to the ground for the

AMP CTRL

jack and to the chassis

ground (a screw section on the chassis) and verify that no conduction

occurs.

Summary of Contents for Boss GT-10

Page 4: ...4 Mar 2008 GT 10 Location of Controls fig panel GT 10 eps...

Page 6: ...6 Mar 2008 GT 10 Exploded View fig bunkai eps L...

Page 7: ...7 Mar 2008 GT 10 fig bunkai eps R...

Page 11: ...11 Mar 2008 GT 10 fig block wiring eps R...

Page 24: ...24 Mar 2008 GT 10 Circuit Board Main Board fig b main 1 eps...

Page 25: ...25 Mar 2008 GT 10 fig b main 2 eps...

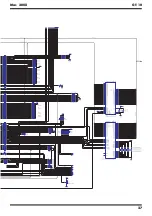

Page 26: ...26 Mar 2008 GT 10 Circuit Diagram Main Board 1 5 fig d main 1 eps L...

Page 27: ...27 Mar 2008 GT 10 fig d main 1 eps R...

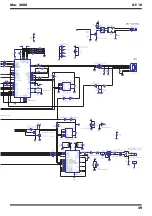

Page 28: ...28 Mar 2008 GT 10 Circuit Diagram Main Board 2 5 fig d main 2 eps L...

Page 29: ...29 Mar 2008 GT 10 fig d main 2 eps R...

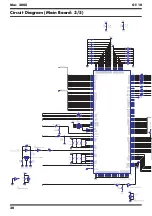

Page 30: ...30 Mar 2008 GT 10 Circuit Diagram Main Board 3 5 fig d main 3 e eps L...

Page 32: ...32 Mar 2008 GT 10 Circuit Diagram Main Board 4 5 fig d main 4 eps L...

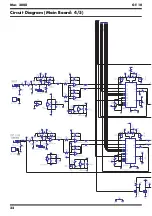

Page 33: ...33 Mar 2008 GT 10 fig d main 4 eps R...

Page 34: ...34 Mar 2008 GT 10 Circuit Diagram Main Board 5 5 fig d main 5 eps L...

Page 35: ...35 Mar 2008 GT 10 fig d main 5 eps R...

Page 36: ...36 Mar 2008 GT 10 Circuit Board SW VR Pedal Bank ENC EXP Board fig b sw 1 eps...

Page 37: ...37 Mar 2008 GT 10 fig b sw 2 eps...

Page 38: ...38 Mar 2008 GT 10 Circuit Diagram SW VR Board fig d sw vr eps L...

Page 39: ...39 Mar 2008 GT 10 fig d sw vr eps R...

Page 40: ...40 Mar 2008 GT 10 Circuit Diagram Pedal Board fig d pedal eps L...

Page 41: ...41 Mar 2008 GT 10 fig d pedal eps R...

Page 44: ...MEMO Mar 2008 GT 10...