9

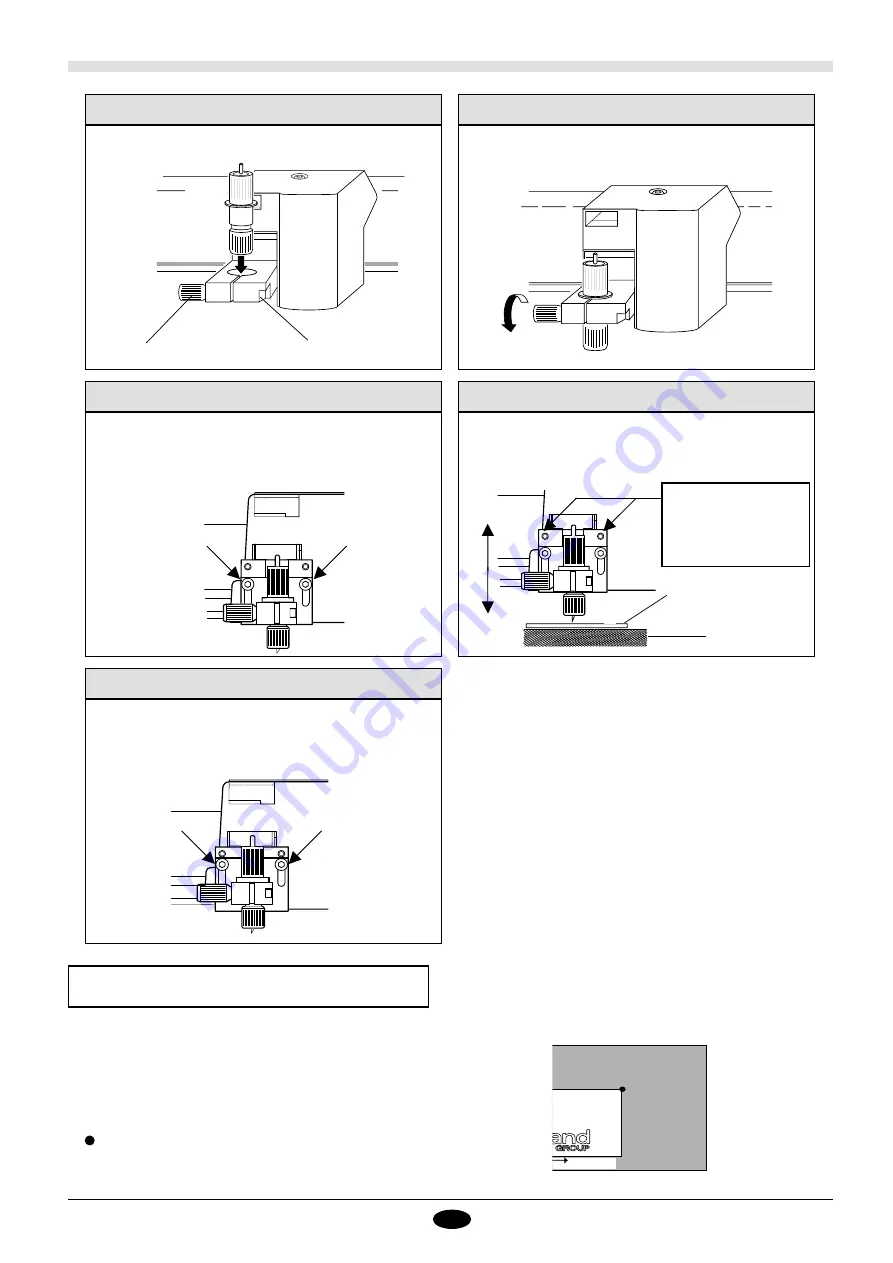

Firmly tighten down the tool mounting screw so that the

blade holder does not move.

Securing the Blade Holder in Place

Loosen the tool setscrew on the tool holder and insert the

blade holder.

Mounting a Blade Holder

Tool setscrew

Tool holder

Adjusting the Height of the Tool Holder 1

When loading a thick material, adjust the height so that the

material does not catch on the blade holder. Use the hex

wrench included with the machine to loosen the screws

shown in the figure.

Adjusting the Height of the Tool Holder 2

If the thickness of the

material is 8 mm

(5/16") or more, use

the upper hole.

The tool holder can be shifted up or down. Adjust it to a

height that allows the tool gap gauge to pass with no

resistance.

Blade gap gauge

Material

Adjusting the Height of the Tool Holder 3

After positioning the blade holder, tighten the screws with

the hex wrench.

7. Setting the Cutting Area

UR

X

The cutting area is determined by setting the LL and UR for the

material on the cutting table. Be sure to make this setting before

performing a cut. Also note that the first time you use this

product, the LL is set to the bottom left corner of the cutting

table, and the UR is set to the upper right corner of the cutting

table.

When LL and UR have been set respectively as the lower-left

and the upper-right, the X axis is horizontal (left-right), and

the Y axis is vertical.

LL is lower left and UR is upper right

Summary of Contents for CAMM-1 PNC-1610

Page 41: ...R12 980109 ...