2

1 cut 50Cm/s

0.250mm 30gf

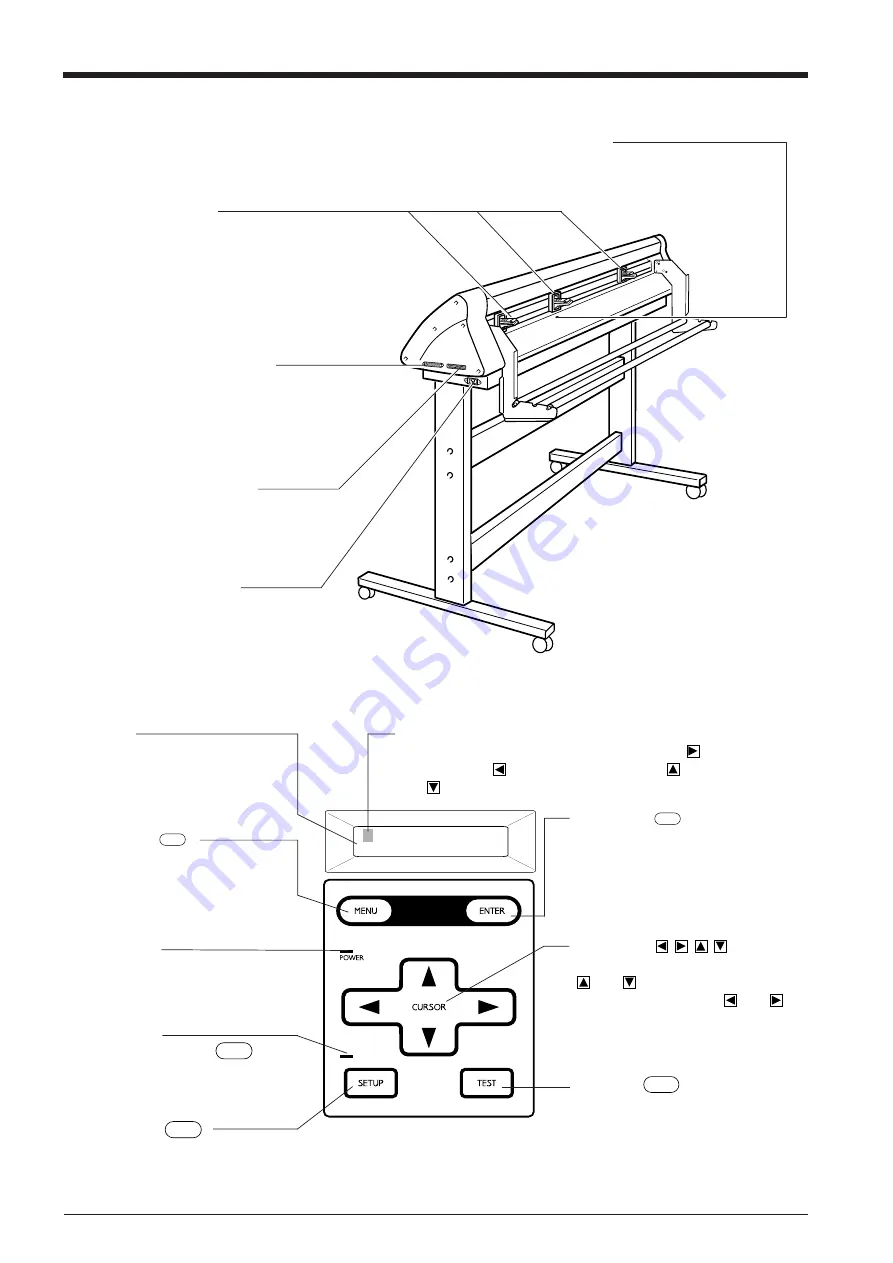

Display

Provides menu display, configuration

preferences, coordinates, as well as

error messages for troubleshooting.

2-3 Operation Panel

MENU Key

MENU

Employed to select among the

available menus, or to cancel the

making of a setting at a particular

menu.

Cursor Keys

Used to move the blinking cursor. The

and

keys are also used to

move the material, and the

and

keys are used to move the tool

carriage.

ENTER Key

ENTER

Press to enter into a subroutine of the

item selected using the cursor keys or

to confirm (save) the value set in

configuration.

TEST Key

TEST

Pressed to execute a cutting test (Use

to confirm material specifications as

well as cutting speed, blade force, and

blade compensation).

SETUP Key

SETUP

Pressing this key after loading a material causes the

material's cutting range to be determined automatically.

Blinking Cursor

Used to select the desired item from the menu. The

key moves it

to the right, the

key moves it to the left, the

key moves it up,

the

key moves it down.

Power LED

This lights up when the power is

switched on.

SETUP LED

This lights up when the

SETUP

key is

pressed to pause the PNC-1860/1410/

1210.

2-2 Rear View

Sheet Loading Lever

When loading media, lift this lever to lower to

pinch rollers. To removing media, lower this

lever to raise the pinch roller.

Parallel (Centronics) Connector

In a parallel configuration, this connector is where you

need to connect the parallel cable in order to commu-

nicate with your computer.

Serial (RS-232C) Connector

In a serial configuration, this connector is

where you need to connect the serial cable that

is used to communicate with your computer.

Power Connector [AC IN]

This jack accepts a standard AC power cord.

Sheet Sensor

When a material is passed through this

portion, this sensor detects the material's

cutting range.

Summary of Contents for Camm-1 Pro GX-640

Page 8: ...v MEMO...

Page 38: ...30 Automatic backspace 13 CHARACTER SET...

Page 41: ...R9 980506...