9

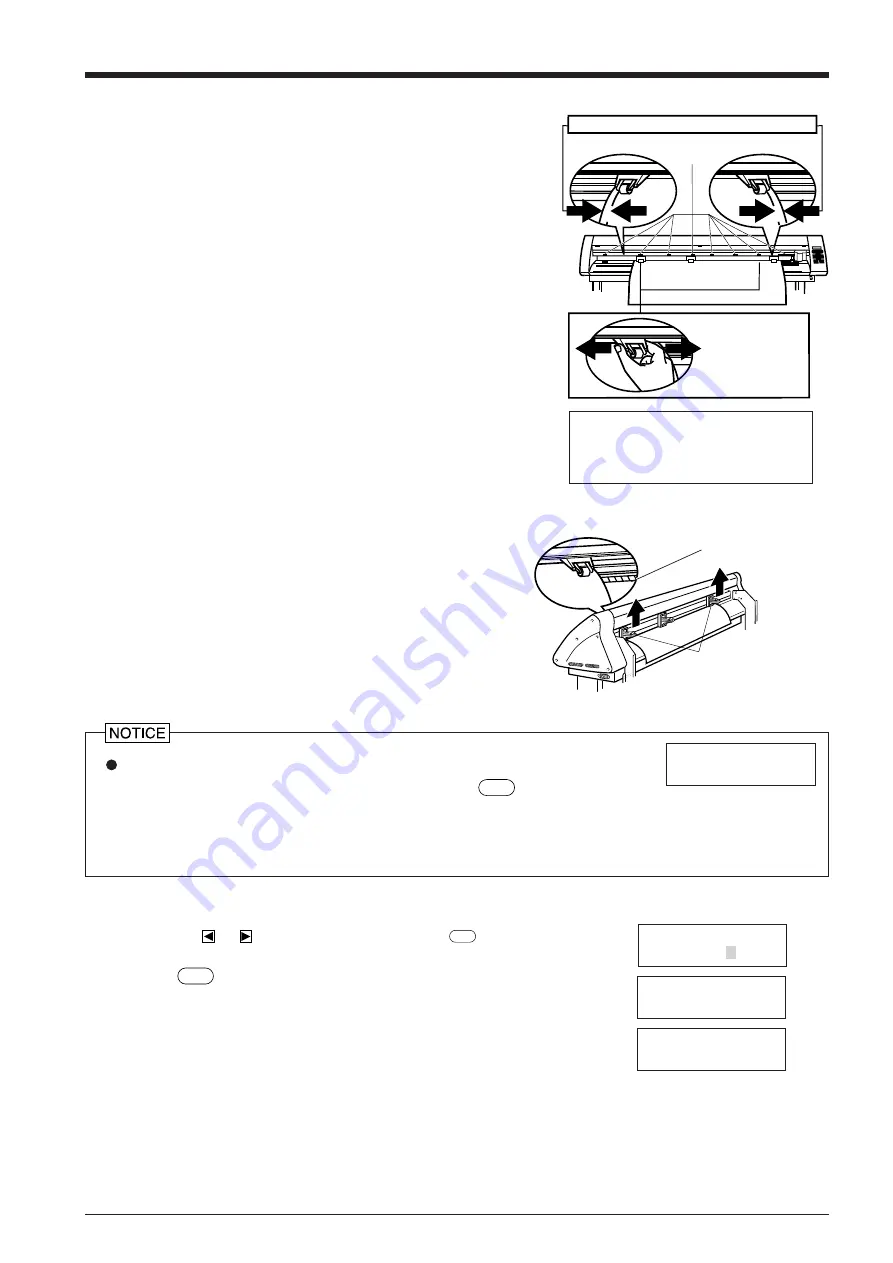

(2) Move the left and right pinch rollers so that they are close to the

respective left and right edges of the material. When using a material

that is wider than 762 mm (30") , move the middle pinch roller to a

position near the center of the left and right pinch rollers. (The PNC-

1210 has no middle pinch roller.) When doing this, make sure that

the grit rollers are under the pinch rollers.

Seals showing the positions of the grit rollers are affixed to the areas

where the carriage moves. You can use these stickers to confirm the

locations of the grit rollers when the grit rollers are hidden by the

material.

If the pinch rollers are difficult to move, try moving the sheet loading

lever on the back of the unit at the same time.

Move the pinch

rollers to inside

the edges of the

sheet

Stickers showing the locations of the

grit rollers

Make sure the left and right margins are the same size

(3) Align the right edge of the material with the two guide lines located in

front of and behind the grit roller on the control panel side, and load

the material so that it is completely straight.

Lift the sheet loading lever on the back of the unit to lower the pinch

roller and clamp the material.

Be sure to move the pinch rollers above the grit rollers when securing a material in the unit.

Moving the pinch roller to the area of the grit roller and pressing the

SETUP

key causes the message

at right to appear.. If this occurs, raise the sheet loading levers and move the pinch rollers to the

proper positions above the grit rollers.

Reposition the material to match this new alignment, then lower the sheet loading levers to hold the material in place.

Change Pinch

Roller Position

(4) When you close the front cover, the message shown at right appears on the control

panel. Press

or

to display “PIECE,” then press the

ENTER

key.

(5) Press the

SETUP

key. The tool carriage will move from side to side and the material will

move forward and backward to detect the size of the material. After this sensing is

finished, the front edge of the material is aligned with the cutting starting position.

(6) If material offset or alignment problems become apparent while the 1860/1410/1210 is

scanning the piece in step (5) above, the material has not been loaded straight. Be sure to

load the material straight. Set the movable left and right pinch rollers inside the material

edges.

Close the front cover

SELECT SHEET

ROLL EDGE PIECE

WIDTH LENGTH

28920 150

PRESS SETUP KEY

When using a material which is narrower than 762 mm (30") , do not

lower the pinch rollers.

Guide line

Before attempting to move the pinch

roller, be sure to lower the sheet

loading lever to raise the pinch roller.

Lift the sheet

loading levers

Material

Summary of Contents for Camm-1 Pro GX-640

Page 8: ...v MEMO...

Page 38: ...30 Automatic backspace 13 CHARACTER SET...

Page 41: ...R9 980506...