12

3-5 Cutting Test - Setting Cutting Speed, Blade Force, and Blade Compensation

For optimum performance, it is necessary to set cutting conditions that match the material, giving consideration to the material's

thickness and type of material. The PNC-1860/1410/1210 has an internal "cutting test" to check the cutting conditions. This

“cutting test” allows you to determine settings for the cutting speed, blade force and the amount of offset.

Experiment with different settings for different types of material and adjust the configuration accordingly.

Procedure

(1) Install a blade and load a material, then close the front cover (see "3-2 Installing the

Cutter" to "3-3 Loading the Material).

Press the

MENU

key until the screen shown at right appears. Use the

,

,

and

keys to move the tool carriage to the place where the cutting test is to be performed. The

tool carriage cannot be moved by pressing the

,

,

and

keys unless the

display shows the screen right.

ORIGIN SET->ENTER

O 0

Then, peel this off

Peel off first

Origin

(Position of the tool installed

in step 1)

Adjusting cutting speed • blade force • blade compensation

With a blade installed, a Material loaded, and the front cover closed, check to make sure that the screen shown below appears on

the display. If a different menu is displayed, press the

MENU

key until the screen shown below appears.

1 CUT 50cm/s

0.250mm 30gf

• Use the

and

keys to move the blinking cursor to the item to be set.

• Then use the

and

keys to change the numerical value, and press the

ENTER

key to enable the setting.

Setting range:

0.00 mm (in increments

of 0.025 mm)

Setting range:

1—85 cm/s.

(In increments of 1 cm/s)

Setting range:

20—350 gf

(in increments of 10 gf)

Blade force

Cutting speed

Blade compensation

• Note that an area of approximately 2 square centimeters (a little less than a square inch) is

required to make a test cutout (given that the tip of the cutter after it has moved is at the

origin at lower-left).

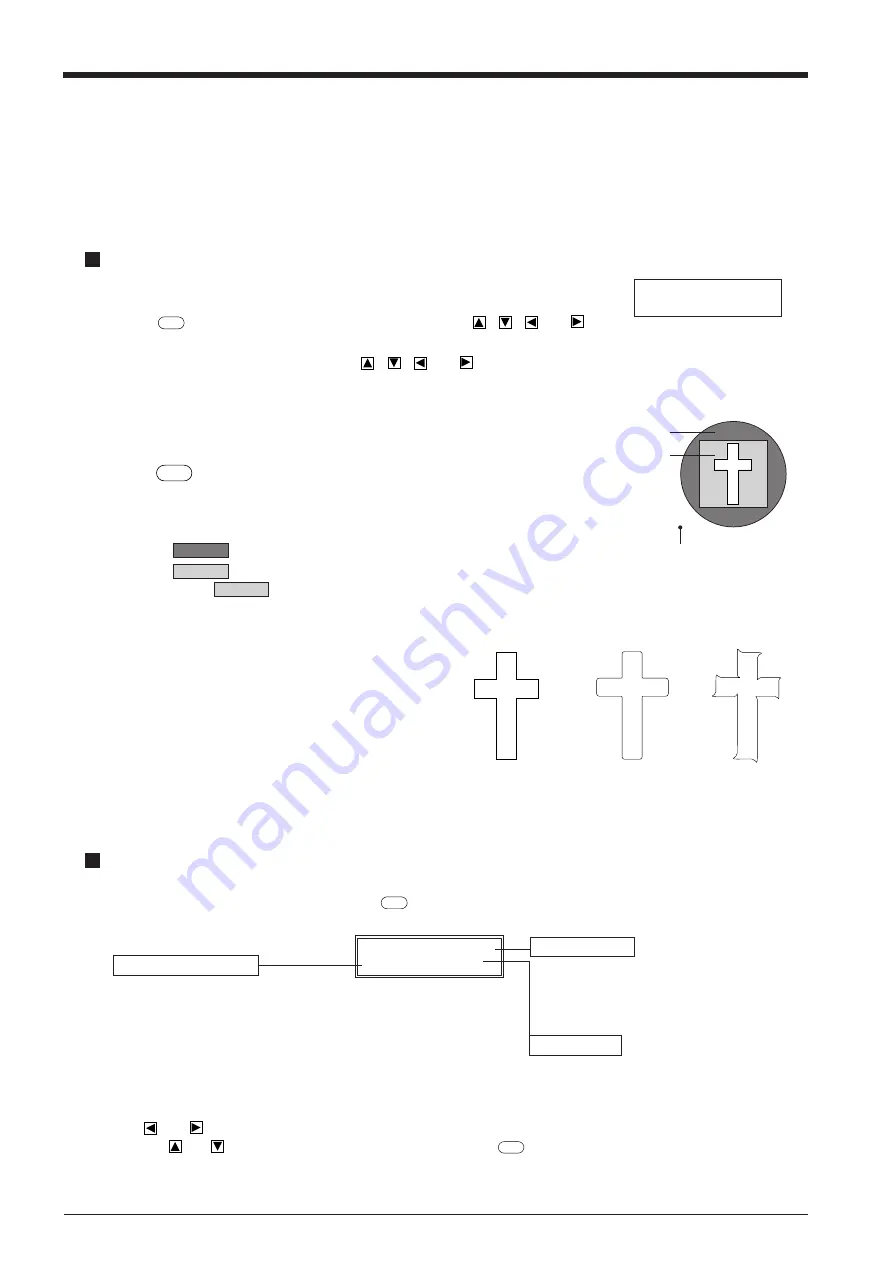

(4) The remaining cross-shaped area is used to check whether

the offset value is set correctly. When the offset value has

been correctly set, the corners of the figure should appear

cleanly cut as shown in

A

of the figure below. If the offset

value is too small, the corners will appear slightly rounded

as illustrated by

B

; an offset value which is too large will

result in a cut figure similar to

C

.

If the material was not cut correctly in steps (1) through (4) of the cutting test, change the cutting conditions.

Repeat the cutting test and adjustment until the optimal cutting speed, blade force, and blade compensation are found.

A

B

C

(2) Press the

TEST

key for 0.5 seconds or more. Cutting test starts.

The resulting cutouts will then appear as illustrated.

(3) Confirm the cutting speed and the blade force. Peel off the round section

(marked by ). Confirm that you can peel off the square section

(marked by ), but do not remove it. Also remove the square

section (marked by ). If the blade leaves a slight trail on the

carrier paper, you have achieved optimum cutting speed and blade force.

Summary of Contents for Camm-1 Pro GX-640

Page 8: ...v MEMO...

Page 38: ...30 Automatic backspace 13 CHARACTER SET...

Page 41: ...R9 980506...