28

The sheet slips away from the pinch rollers during the cutting process

Make sure the sheet is parallel

with the grit roller.

If the front edge of the sheet you are working with is at an angle, cut off the odd-shaped

part to make it straight, then align it so that it is parallel with the grit roller.

If the sheet is fed for a long distance, the sheet will be less likely to slip out of

alignment if the pinch rollers are moved inward slightly (5 to 25 mm).

When a roll sheet is loaded, use the display menu “AREA” function to feed a sheet by

the length to be used (ensure a small margin by setting a length that is about 0.1 m

longer than the cutting data), make sure the pinch rollers are still in contact with the

sheet (not off the left or right edges, or on the edges), and then cut.

If the sheet is pulled while cutting it is more likely that sheet misalignment and motor

errors will occur.

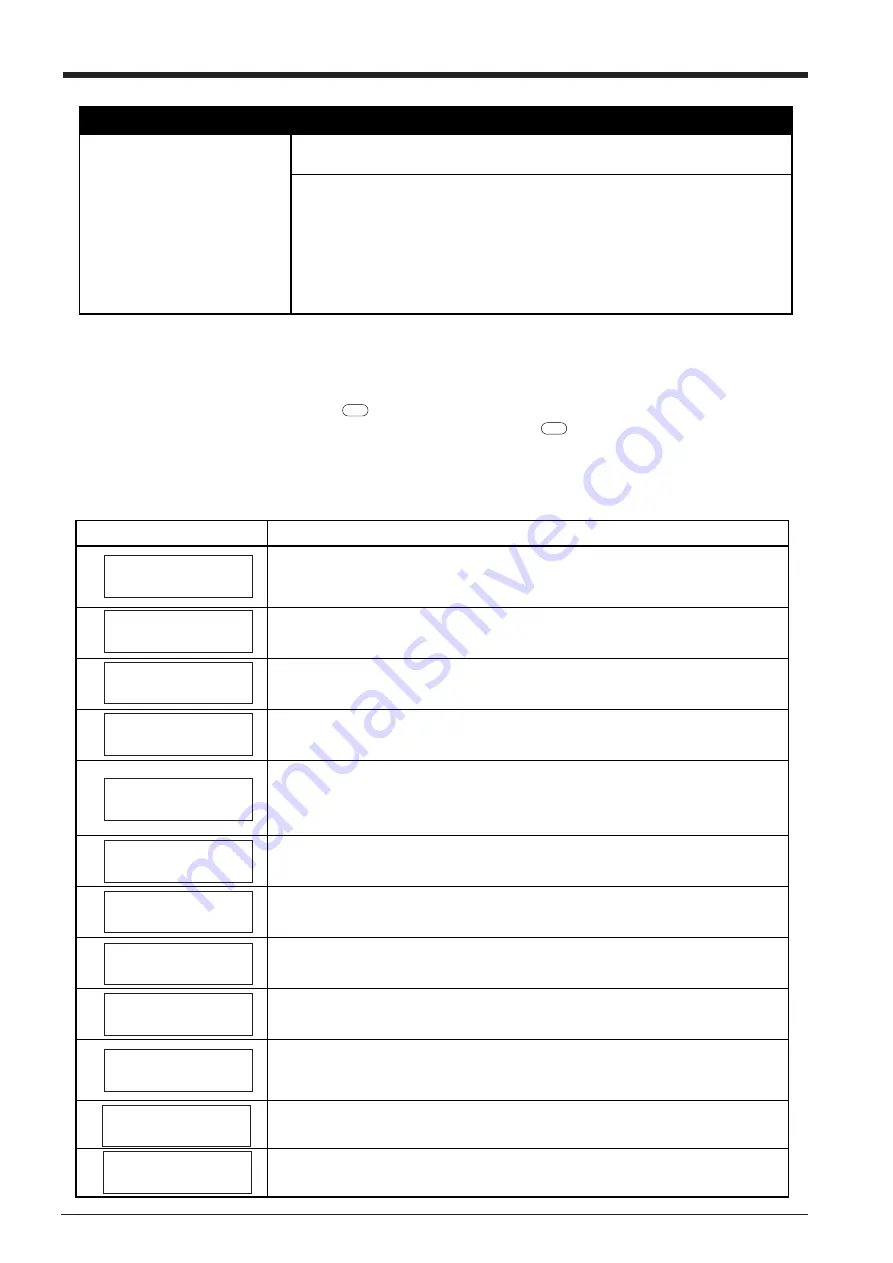

11-2 Error messages

An error message will appear if incoming data has any of the errors listed in table. Since the error is shown in the display for

informational purposes, the data transfer continues and you are allowed to perform the next operation.

To get the error message to go away, press the

ENTER

key.

Note that even though the error message is no longer displayed after you press thee

ENTER

key, the PNC-1860/1410/1210 will retain

in memory the fact that the error occurred. To clear the error internally, you can give the default instruction, IN; or the error code

output instruction, OE. (The error can be cleared by turning the power off.)

The error messages and their meanings are as follows:

Error message

Meaning

Appears if an instruction that the PNC-1860/1410/1210 cannot interpret is sent. This

error is generated if an instruction from the “mode2” set is sent when the unit has been set

to recognize “mode1,” or viceversa. Change the setting for the recognized instruction set,

using the control panel, and this error should no longer occur.

Appears if the number of parameters differs from the permissible number.

Appears if the value specified for a parameter is out of the permissible range.

Appears if an unusable character is specified.

Appears if an output instruction is sent from the computer during execution of a previous

output instruction. More precisely, there is a certain amount of delay between the moment

an output instruction is given and the instant actual output begins. This error message

appears if the new output request arrives during this delay time. (The delay time can be set

using the [ESC].M instruction.)

Appears if a device control instruction that the PNC-1860/1410/1210 cannot interpret is

sent.

Appears if an invalid parameter has been specified for a device control instruction.

Appears if the value for a device control instruction parameter exceeds the permissible

limit.

Appears if the number of parameters for a device control instruction is more than that

permissible.

Appears if a framing error, parity error, or overrun error occurs at the time of data

reception.(There is a problem with one of these settings: Baud Rate, Parity, Stop Bits, or

Data Bits. The protocol settings for the PNC-1860/1410/1210 must be made correctly in

order to match the settings your computer is set to use.)

Appears if the I/O buffer has overflowed.(There is a problem with the connecting cable, or

the settings for Handshaking. Make sure you are using a cable appropriate for the

computer being used. Also, check that the setting for Handshaking is correct.)

Appears if a communication error other than “Er10” through “Er16”, one uninterpretable

by the PNC-1860/1410/1210, occurs during data communications.

Er1:Command

Not Recognized

Er2:Wrong Number

of Parameters

Er3:Out of

Parameter range

Er5:Unknown

Character Set

Er10:Output

Request Overlap

Er11:Command

Not Recognized

Er12:Wrong

Parameter

Er13:Out of

Parameter range

Er14:Termination

Error

Er15:Framing/

Parity Error

Er18:

Indeterminate

Er16:Buffer

Overflow

Summary of Contents for Camm-1 Pro GX-640

Page 8: ...v MEMO...

Page 38: ...30 Automatic backspace 13 CHARACTER SET...

Page 41: ...R9 980506...