31

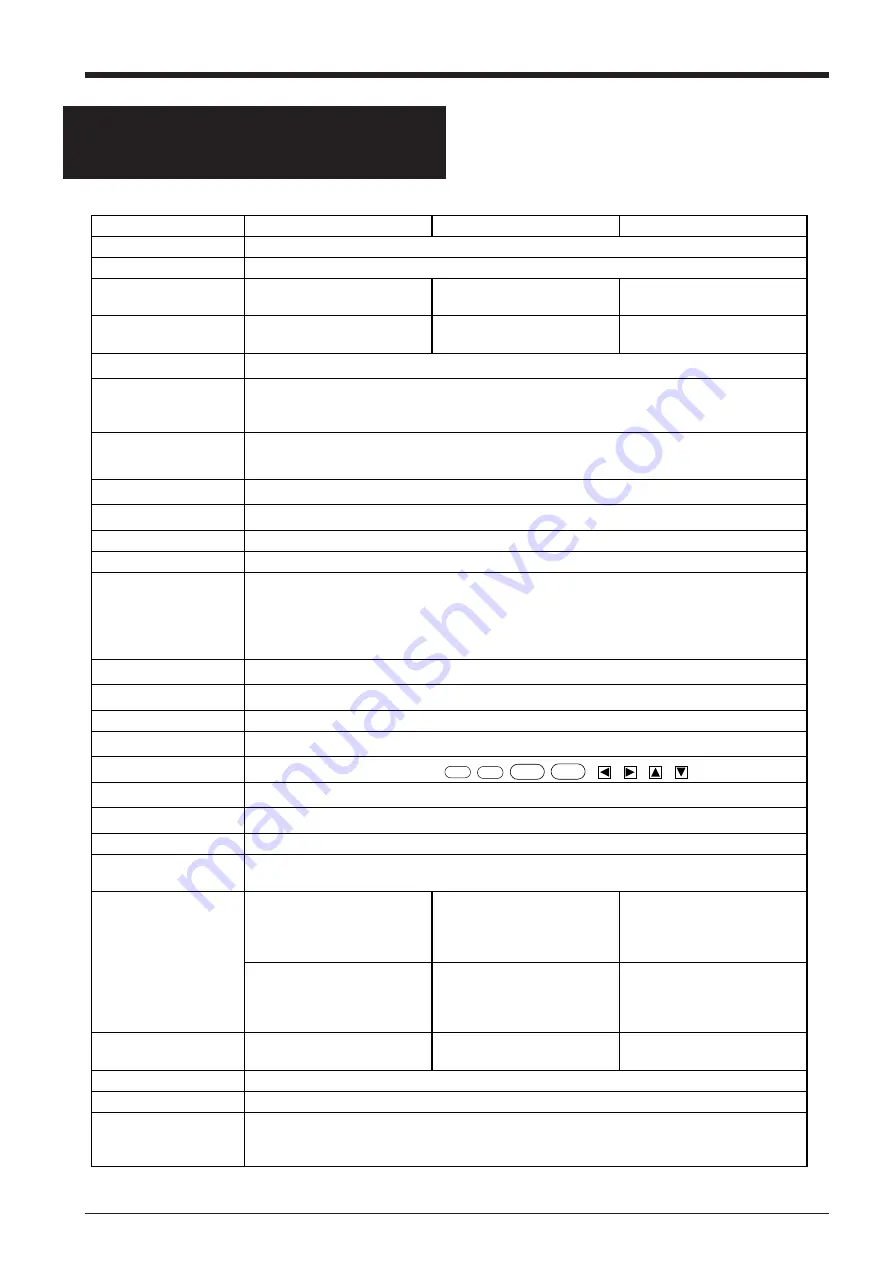

PNC-1860

PNC-1410

PNC-1210

Mechanism

Media-movement method

Driving method

Digital control servo motor

Maximum cutting area

1195 mm (W) x 24998 mm (L)

(47"x 984-1/2")

889 mm (W) x 24998 mm (L)

(35" x 984-1/2")

585 mm (W) x 24998 mm (L)

(23" x 984-1/8")

Acceptable sheet

(paper) widths

90 mm—1372 mm

(3-1/2"—54")

90 mm—1067 mm

(3-1/2"—42")

50 mm—762 mm

(1-15/16"—30")

Number of tools

1

Tools

Cutters: special cutter for CAMM-1 series

Pens: Water-based fiber-tipped pens, Thick water-based fiber-tipped pens (options) and

32 color plotter pens (options)

Max. cutting speed

During cutting: 850 mm/sec. (in all directions)

During tool-up: 1202 mm/sec. (in 45° direction)

Cutting speed

10 mm/sec.—850 mm/sec. (in increments of 10 mm/sec.)

Blade force

20 gf—350 gf (in increments of 10 gf)

Software resolution

0.025 mm/step

Distance accuracy

Error of less than +/- 0.2% of distance travelled, or 0.1mm, whichever is grater

Repetition accuracy

0.1 mm or less (excluding stretching/contraction of the sheet)

• Range for assured repetition accuracy (*)

For sheets with a width exceeding 610 mm (24"): Length 4,000 mm (157-7/16") (PNC-1860/

1410 only) For sheets with a width of 610 mm (24") or less : Length 8,000 mm (315-15/16")

Interface

Parallel (Centronics compatible), Serial (RS-232C)

Buffer size

1 Mbyte (Expandable up to 3 Mbyte)

Instruction system

CAMM-GL III (mode1 and mode2)

Switches

Power switch

Control switches

LED

POWER LED, SETUP LED

Display

Liquid crystal display unit; 16-character by 2 lines

Power consumption

1.0 A/117V, 0.5A/220-230V, 0.5A/230-240V

Acoustic noise level

Cutting mode: under 62dB (A) Standby mode: under 40dB (A)

(According to ISO 7779)

Dimensions

(with stand)

1575 mm (W) x 300 mm (D)

x286 mm (H)

(62-1/16" (W) x 11-13/16" (D)

x 11-5/16" (H))

1270 mm (W) x 300 mm (D)

x286 mm (H)

(50-1/16" (W) x 11-13/16" (D)

x 11-5/16" (H))

965 mm (W) x 300 mm (D)

x296 mm (H)

(38" (W) x 11-13/16" (D) x

11-11/16" (H))

1575 mm (W) x 732 mm (D)

x1145 mm (H)

(62-1/16" (W) x 28-7/8" (D) x

45-1/8" (H))

1270 mm (W) x 732 mm (D)

x1145 mm (H)

(50-1/16" (W) x 28-7/8" (D) x

45-1/8" (H))

965 mm (W) x732 mm (D)

x1145 mm (H)

(38" (W) x 28-7/8" (D) x

45-1/8" (H))

Weight

(with stand)

38 kg (83.8 lb.)

(66.5 kg (146.6 lb.)

28.5 kg (62.8 lb.)

(55 kg (121.2 lb.)

22.5 kg (49.6 lb.)

(42 kg (92.6 lb.)

Temperature

5—40°C (41—104°F)

Humidity

35%—80% (non-condensing)

Accessories

Power cord, Blade holder, Blade for sheet, Alignment tool, Test-use sheet, Test-use application

tape Separate cutter, Tweezers, Test-use water based fiber tipped pen, Test-use high-quality paper,

User's manual, CAMM-1 DRIVER for windows 3.1: 1, CAMM-1 DRIVER for windows: 95: 1,

SPECIFICATIONS

For items indicates by an asterisk "*", please see the following page.

ENTER

,

MENU

,

TEST

,

SETUP

,

,

,

,

SPECIFICATIONS

Summary of Contents for Camm-1 Pro GX-640

Page 8: ...v MEMO...

Page 38: ...30 Automatic backspace 13 CHARACTER SET...

Page 41: ...R9 980506...