4-3 Making Simple Changes to the Printer Settings to Match the Media

71

Chapter 4 Feature Reference

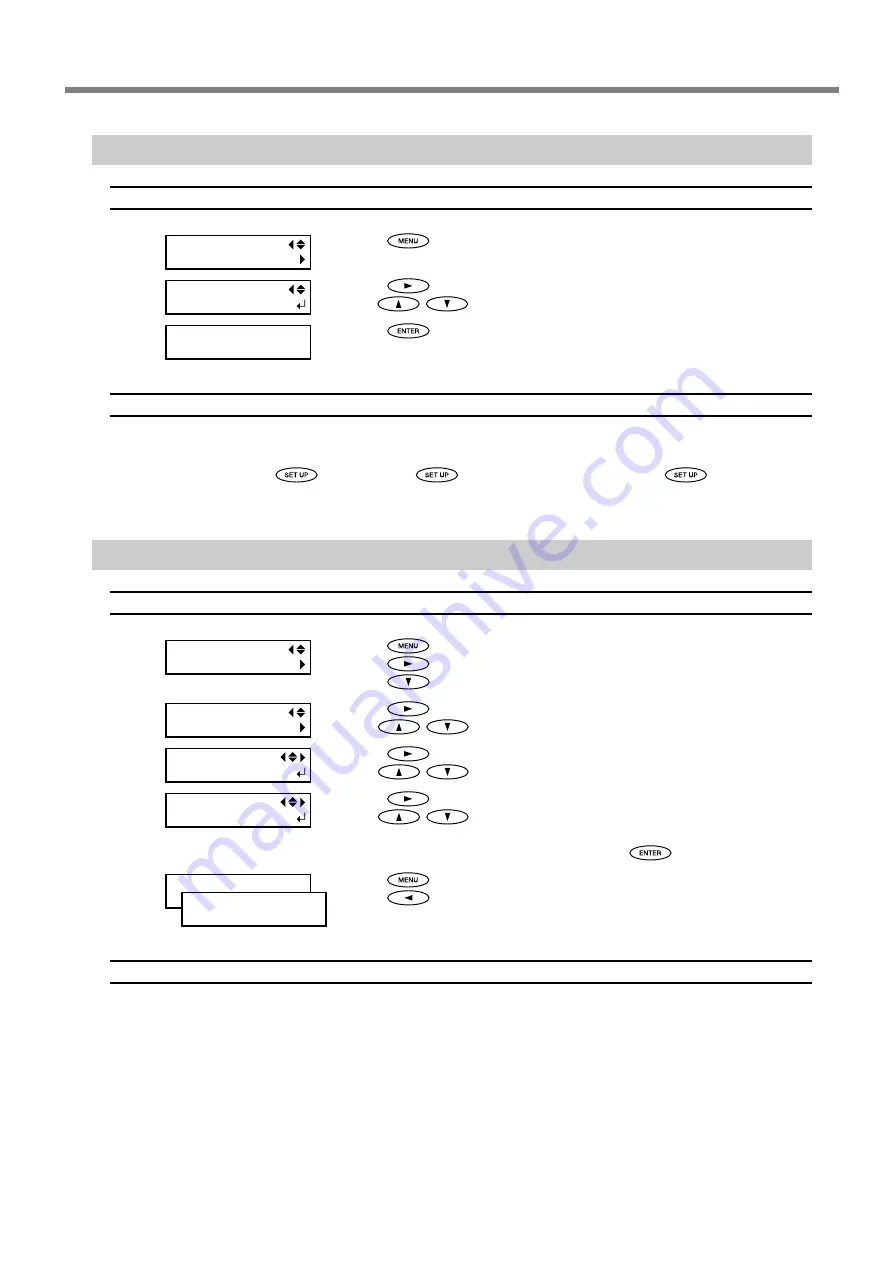

Loading a Saved Preset

Procedure

➊

Press

.

➋

Press

twice.

Use

to select the name of a present you want to load.

➌

Press

to load.

The settings are changed and the screen shown in the figure appears.

Description

This loads a saved preset. You can select any one of eight types of presets. (When no names have been assigned, you

select from among NAME1 through NAME8.)

If you load a preset while

is illuminated,

goes dark. To start printing, press

once more and

redo the preparations for printing.

Assigning a Name to a Preset

Procedure

➊

Press

.

Press

.

Press

twice.

➋

Press

.

Use

to select any one from NAME1 to NAME8.

➌

Press

.

Use

to enter a character.

➍

Press

.

Use

to enter the next character.

Enter the following characters in the same way.

When you're finished entering text, press

.

➎

Press

.

Press

to go back to the original screen.

Description

This assigns a name to a saved preset. Using media names may aid recognition and clarity.

The characters you can enter are "A" through "Z," "0" through "9," and the "-" character. You can enter up to 15

characters, including spaces.

MENU

PRESET

LOAD

NAME1

SETUP SHEET

PRESET

NAME

NAME

S_

NAME

NAME1

NAME

SAMPLE_

W 1839 mm

SETUP SHEET

Summary of Contents for Hi-Fi Express FP-740

Page 22: ...20 ...

Page 23: ...21 Chapter 1 Introduction ...

Page 28: ...26 ...

Page 29: ...27 Chapter 2 Operation ...

Page 50: ...48 ...

Page 51: ...49 Chapter 3 Maintenance and Adjustment ...

Page 68: ...66 ...

Page 69: ...67 Chapter 4 Feature Reference ...

Page 100: ...98 ...

Page 101: ...99 Chapter 5 What to Do If ...

Page 112: ...110 ...

Page 113: ...111 Chapter 6 Specifications ...

Page 118: ...116 ...

Page 119: ......

Page 120: ...R2 070228 ...