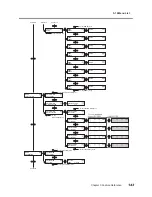

6-2 Attractive Printing Is Impossible

152

Chapter 6 What to Do If

Chapter 6 What to Do If

P. 132, "Saving Optimized Media Settings As Preset

Values"

P. 133, "Loading a Saved Preset"

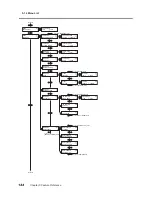

Colors Are Unstable or Uneven

Did you shake the ink cartridges gently

before installing them?

Before you install a new ink cartridge, gently shake

the cartridge.

Is the media wrinkled?

If the media is wrinkled and comes loose from the

platen, colors may be uneven or printing quality

may suffer.

P. 156, "Media Wrinkles or Shrinks, or Feed Is Unstable"

Is the media sagging?

Performing printing using sagging roll media makes

uneven colors more likely.

Was printing paused partway through?

When printing is paused, the coloring at the seam

may be altered when printing resumes. Avoid paus-

ing printing. With the factory-default settings, print-

ing pauses when an ink cartridge runs empty. Before

you perform lengthy printing, check the amount of

ink remaining in the ink cartridges. Printing may

also pause when data is not sent from the computer

quickly enough.

Are the operating parameters set to appro-

priate values?

Depending on the settings for such menu items as

[FULL WIDTH S] and [PERIODIC CL.], uneven colors

may occur. If the settings have been changed, try

restoring them to their default values.

P. 94, "Speeding Up Printing for Narrow Media"

P. 95, "Preventing Soiling of the Media and Dot Drop-out

During Printing"

Is the printer installed in a level and stable

location?

Never install the machine in a location where it is

tilted or where it may wobble or experience vibration.

Also, ensure that the print heads are not exposed to

wind or blown air. These factors may lead to missing

dots or reduced printing quality.

Is the printer being used in a location sub-

ject to severe changes in the operating

environment?

Large fluctuations in temperature or humidity while

printing is in progress may cause the colors to change

partway through. When you're performing printing,

use the machine in a location where temperature and

humidity are stable.

Are the settings for the [PRESET] menu item

appropriate?

If the settings selected with the [PRESET] menu item

are not suitable for the type of media, printing may

be adversely affected. Choose settings optimized to

the media you're using.

P. 132, "Saving Optimized Media Settings As Preset

Values"

P. 133, "Loading a Saved Preset"

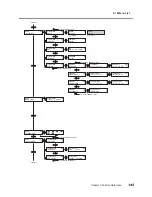

The Media Becomes Soiled When Printed

Do the print heads contact the media?

The height of the print heads may be too low. Also, if

the media is not loaded and set up correctly, it may

wrinkle or come loose and strike the heads.

P. 106, "Adjusting Head Height to Match Media Thick-

ness"

P. 156, "Media Wrinkles or Shrinks, or Feed Is Unstable"

Are the print heads dirty?

The following may cause ink to drip on the media

during printing.

• Buildup of fibrous dust (lint) around the

heads.

• Ink transferred to the heads due to rubbing

against the media.

If this happens, clean the heads using the clean-

ing kit. We recommend carrying out periodic head

cleaning.

P. 70, "Cleaning Using the Cleaning Kit"

Are the pinch rollers or media clamps

dirty?

Summary of Contents for LEC-300A

Page 24: ...22 ...

Page 25: ...Chapter 1 Introduction 23 ...

Page 32: ...30 ...

Page 33: ...Chapter 2 Basic Operation 31 ...

Page 56: ...54 ...

Page 57: ...Chapter 3 Operation of the Me dia Take up System 55 ...

Page 65: ...Chapter 4 Maintenance and Adjustment 63 ...

Page 91: ...Chapter 5 Feature Reference 89 ...

Page 151: ...Chapter 6 What to Do If 149 ...

Page 164: ...162 ...

Page 165: ...Chapter 7 Specifications 163 ...

Page 173: ...171 ...

Page 174: ...172 ...

Page 175: ...173 ...

Page 176: ...174 ...

Page 177: ...175 ...

Page 178: ...176 ...

Page 179: ......

Page 180: ...R1 091026 ...