Summary of Contents for LEC-300A

Page 24: ...22 ...

Page 25: ...Chapter 1 Introduction 23 ...

Page 32: ...30 ...

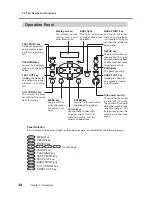

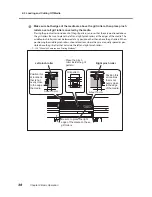

Page 33: ...Chapter 2 Basic Operation 31 ...

Page 56: ...54 ...

Page 57: ...Chapter 3 Operation of the Me dia Take up System 55 ...

Page 65: ...Chapter 4 Maintenance and Adjustment 63 ...

Page 91: ...Chapter 5 Feature Reference 89 ...

Page 151: ...Chapter 6 What to Do If 149 ...

Page 164: ...162 ...

Page 165: ...Chapter 7 Specifications 163 ...

Page 173: ...171 ...

Page 174: ...172 ...

Page 175: ...173 ...

Page 176: ...174 ...

Page 177: ...175 ...

Page 178: ...176 ...

Page 179: ......

Page 180: ...R1 091026 ...