Advanced Calibration

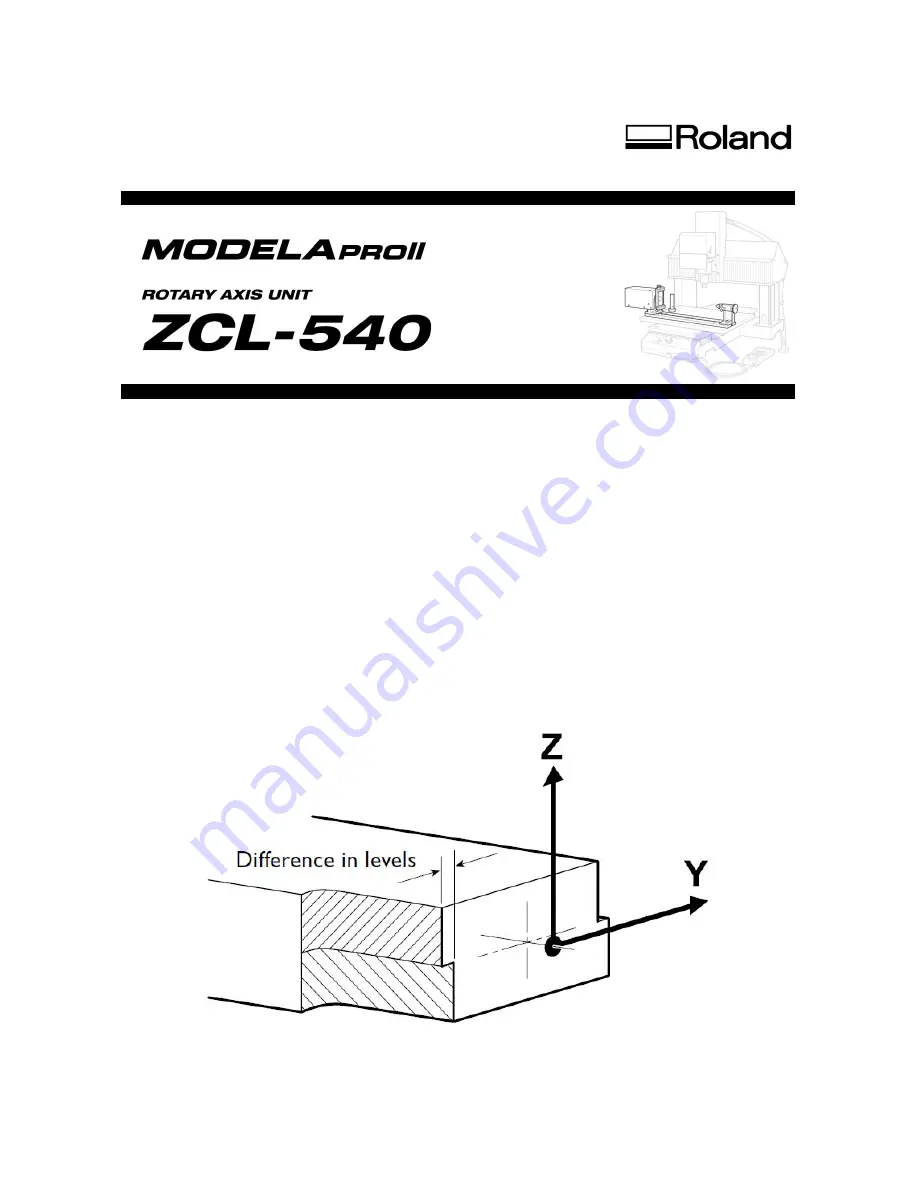

The purpose of this document is to assist users of the Roland MDX-540

fine tune the accuracy of their machine when using the 4th-axis option

(ZCL-540) – The following steps will assist users who observe any shifts

or offsets when performing double sided milling. We will cover two

sections:

•

Section 1

- Setting Origins

•

Section 2

– Manual Adjustments