3

3

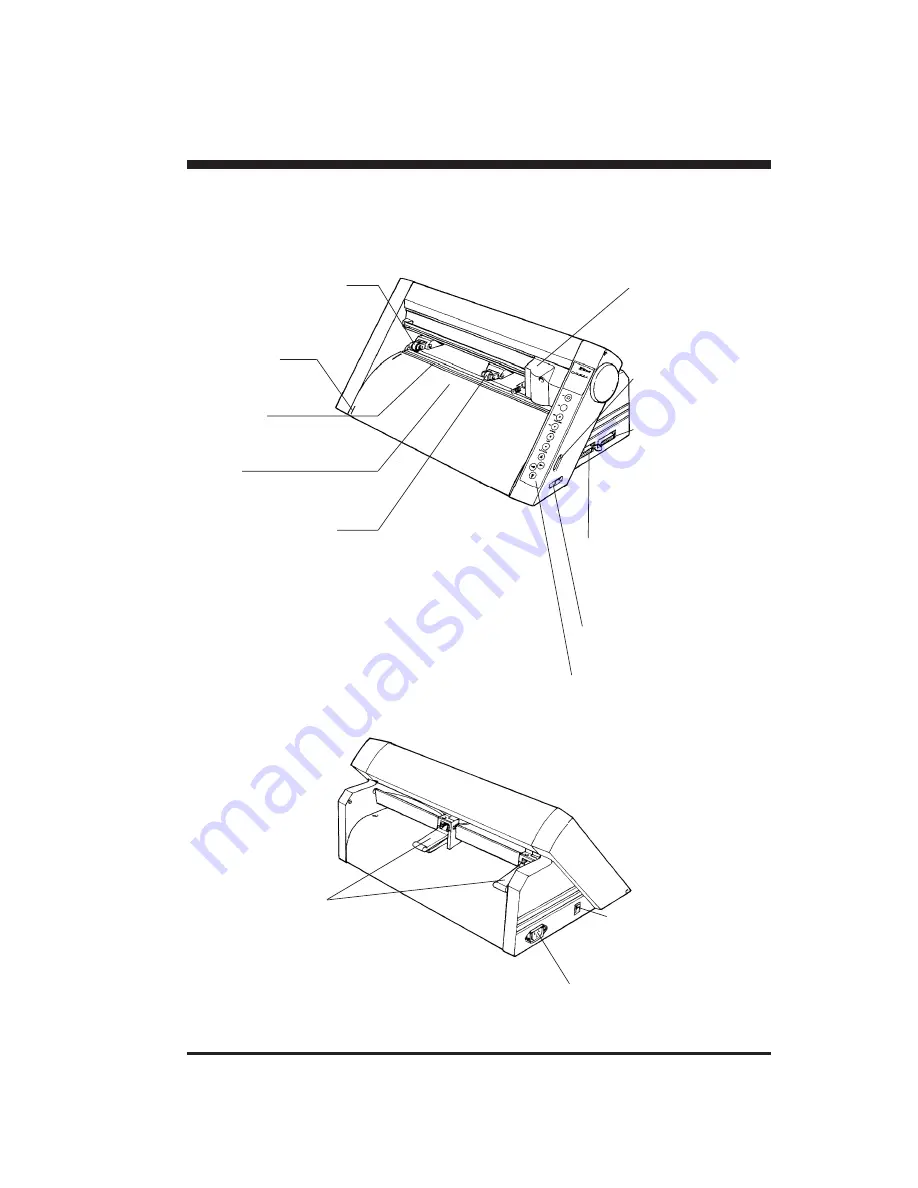

PART NAMES AND FUNCTIONS

• Front View

Tool Carriage

The tool carriage is where the

blade holder is mounted. The

tool carriage performs the

cutting by moving the tool

left/right or up/down.

Stationary Pinch Roller

During cutting, this roller holds the

sheet down so that it is in contact

with the grit roller.

Guide Lines

Align the sheet with these

lines when loading.

Grit Roller

Grasps and moves the sheet during

cutting.

Platen

The sheet is moved over the platen during

the cutting process.

Movable Pinch Roller

During cutting, this roller holds the sheet down so

that it is in contact with the grit roller. It can easily

be slid to the right or left, and should be positioned

to suit the width of the sheet being used.

Serial (RS-232C)

Input Connector

In a serial configuration, this

connector is where you need

to connect the serial cable

that is used to communicate

with your computer.

Operation Panel

These are keys for making settings for the

various functions.

• Rear View

DIP Switches

Used to make various

settings.

Parallel (Centronics) Input

Connector

In a parallel configuration, this

connector is where you need to connect

the parallel cable that is used to

communicate with your computer.

Pen Force Control Slider

Sets the blade force to be used with the

tool.

Sheet Loading Lever

Used to raise or lower the pinch rollers when

loading or unloading a sheet.

Power Connector (AC IN)

This jack accepts connection of the power

cord.

Power Switch

When pushed toward [

I

], power is

turned on.

Push toward [

O

] to turn it off.