4-30

4 Adjustment

4

1

2

3

4-6 LINEAR ENCODER SETUP (Referential Time : 10min.)

[About LINEAR ENCODER SETUP]

LINEAR ENCODER SETUP is necessary for the machine to recognize the width by the software coordinates.

It is also necessary for checking whether the encoder module can read the scale correctly in the whole width.

Lower the Pinch Rollers.

Make sure to unload the media when it is set on the

machine.

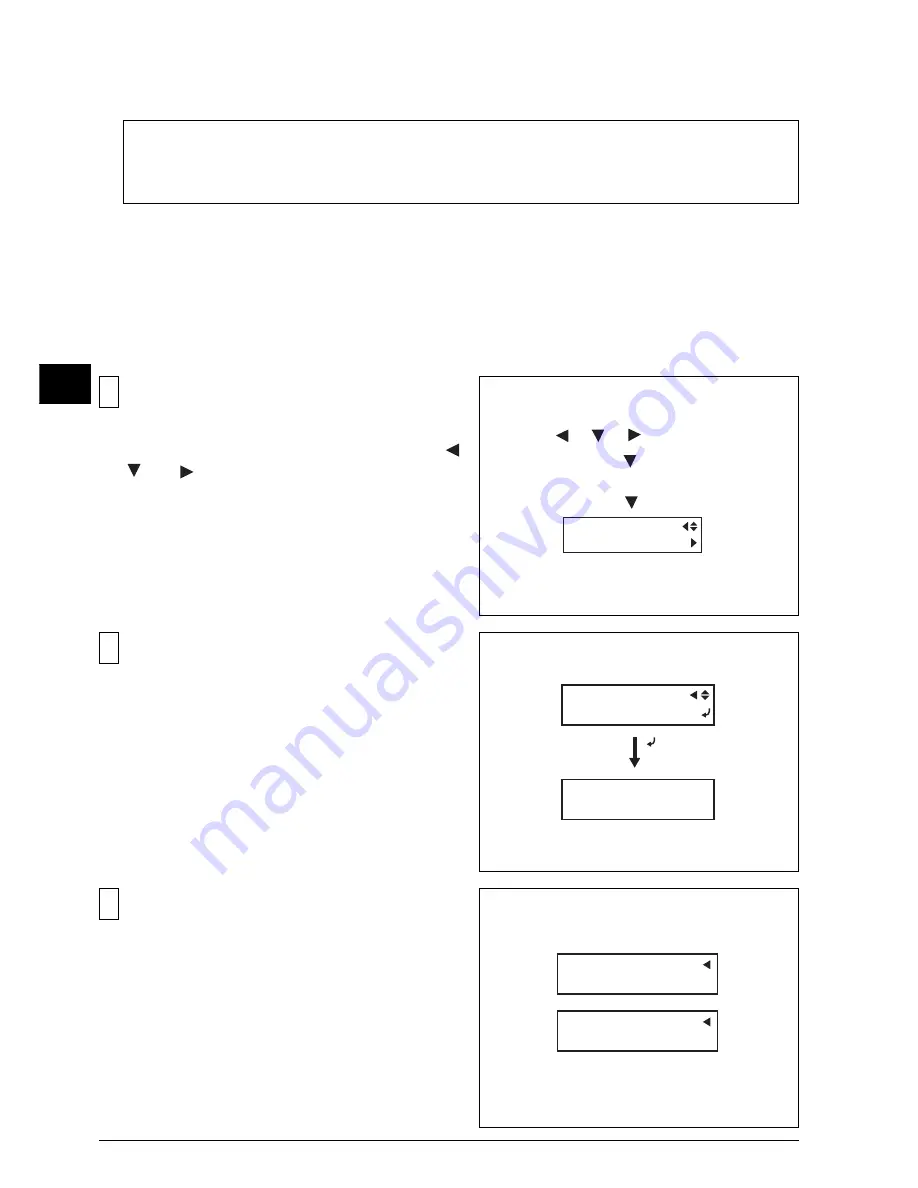

Then, turn on the SUB POWER SW while pressing [ ],

[ ] and [ ] keys to enter the SERVICE MODE.

Select the [LINEAR ENCODER] menu in the SERVICE

MENU and press the [ENTER] key.

Either of the messages will appear at the completion

of the set up.

In case of SETUP error, check the followings.

[ ], [ ], [ ] + POWER ON

[ MENU ] key

SERVICE MENU

Menu

LINEAR ENCODER

SETUP COMPLETED

LINEAR ENCODER

SETUP FAILED

SERVICE MENU

LINEAR ENCODER

NOW PROCESSING..

POS: 1361.00mm

1. Dirt/Scratch on the ENCODER SCALE.

2. Dirt/Scratch on the ENCODER MODULE.

3. ENCODER SCALE is not between the

ENCODER MODULE.

4. Backlash of the CARRIAGE MOTOR GEAR

and the DRIVE GEAR.

5. Fixation between the CARRIAGE and the CARRIAGE

WIRE.

6. Bad Contact in the cables.

Summary of Contents for SP-300

Page 128: ...2 Electrical Section 2 2 2 2 2 MAIN BOARD DIP SW DIP SW bit 1 bit 8 Always OFF ...

Page 134: ...2 Electrical Section 2 8 2 2 3 SERVO BOARD ...

Page 135: ...2 Electrical Section 2 9 2 ...

Page 140: ...2 Electrical Section 2 14 2 2 4 HEATER BOARD ...

Page 189: ...3 Replacement of Main Parts 3 42 3 9 Carry out the LINEAR ENCODER SETUP ...