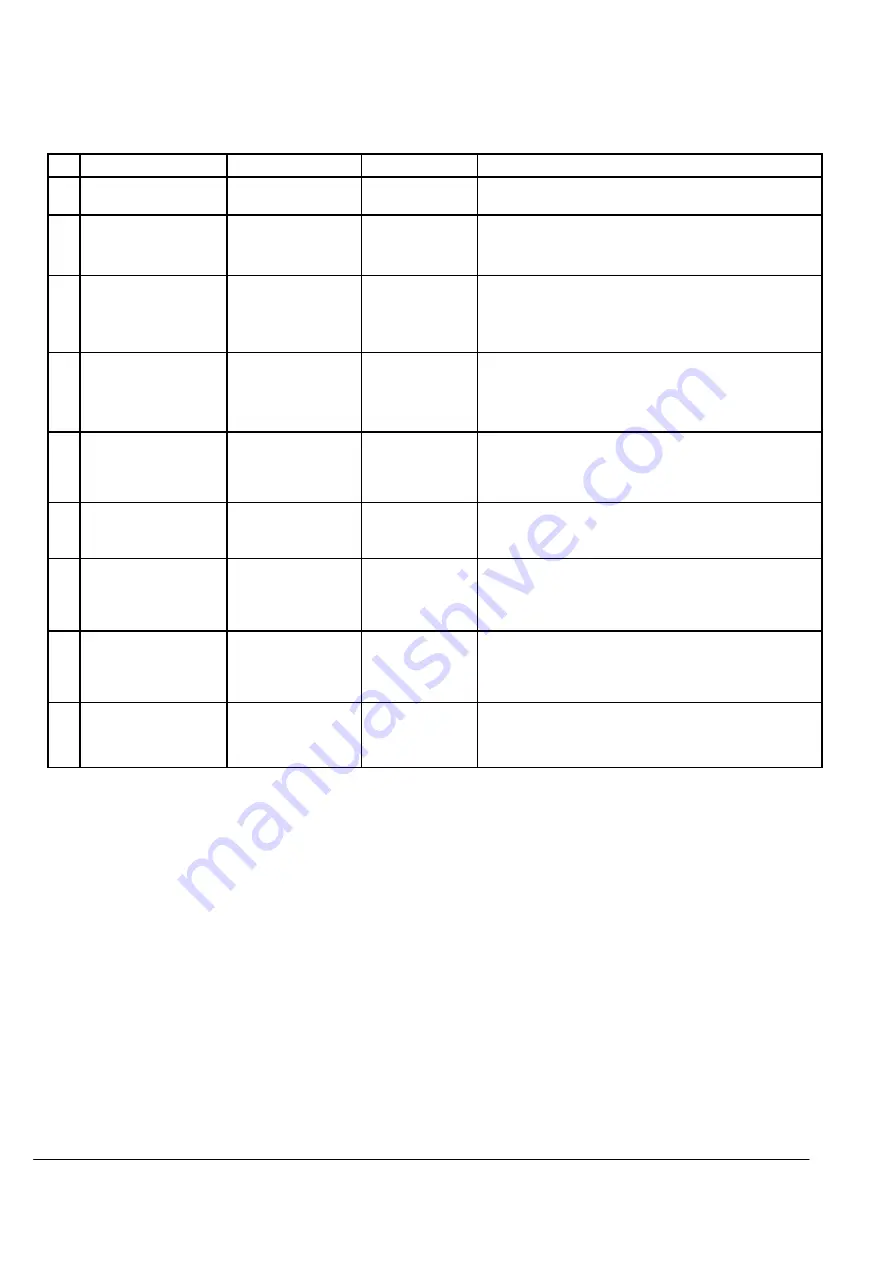

6-6 STITCH CUT

NO

CHECKING POINT

ACTION

REFERENCE

OUTLINE

1

Blade tip is wearing out

Replace the Blade

When blade wears out, it will be caught by the vinyl and

results in stitch cut.

2

Blade Holder tip is

caught by the media

Don't use Blade

Extension Function

Blade holder tip gets caught by the vinyl depending on

the surface condition or type of media. In this case, try

cutting without using the blade extension function.

3

Scratch in Cutter

Protection

Replace the Cutter

Protection

[3-12 Cutter

Protection _

Replacement]

Cutter Protection is where the blade lands for cutting. If

there is scratch in the Cutter Protection, blade is caught

by the vinyl because it sticks deeper into the vinyl and

results in stitch cut.

4

Bearing inside Blade

Holder doesn't rotate

smoothly.

Replace the Blade

Holder

There are bearings inside the Blade Holder. When the

bearings don't rotate smoothly, direction of the blade

slightly shifts from the correct direction and therefore, it

will be caught by the vinyl which results in stitch cut.

5

Tool Height is not

correct

Tool Height

Adjustment

[4-11 Tool Height

Adjustment]

When Tool Height is not adjusted, blade hits the Bed

strongly and bounces which results in stitch cut. In most

cases, stitch cut at the beginning is caused by this

reason.

6

Tool Pressure is not

correct

Tool Pressure

Adjustment

[4-12 Tool

Pressure

Adjustment]

When Tool Pressure is not adjusted, blade hits the Bed

strongly and bounces which results in stitch cut.

7

Holder part of Tool

Carriage / Tool

Carriage ASS'Y are

loose.

Fix Holder part of

Tool Carriage / Tool

Carriage ASS'Y

again.

[3-4 Tool Carriage

_ Replacement]

When Holder part of Tool Carriage / Tool Carriage

ASS'Y are loose, the cutting is unstable and results in

the stitch cut.

8

Tool doesn't move

up/down smoothly

Replace the Tool

Carriage

[3-4 Tool Carriage

_ Replacement]

When Tool doesn't move up and down smoothly, blade

sometimes hits the Bed strongly and bounces which

results in stitch cut. In most cases, stitch cut at the

beginning is caused by this reason.

9

Solenoid Driver IC on

Servo Board is broken

Replace IC2 on the

Servo Board

When Solenoid Driver IC breaks, sometimes high

pressure will be generated. In this case, blade hits the

Bed strongly and bounces which results in stitch cut.

6-5

Summary of Contents for VersaCamm SP-540V

Page 31: ...2 10 2 3 SERVO BOARD ...

Page 32: ...2 11 ...

Page 37: ...2 16 2 4 HEATER BOARD ...

Page 40: ...2 19 2 5 SUB BOARD ...

Page 88: ...3 43 9 Carry out the LINEAR ENCODER SETUP ...

Page 150: ...4 53 4 9 Check and make sure that the tension is within the range If not adjust it again ...