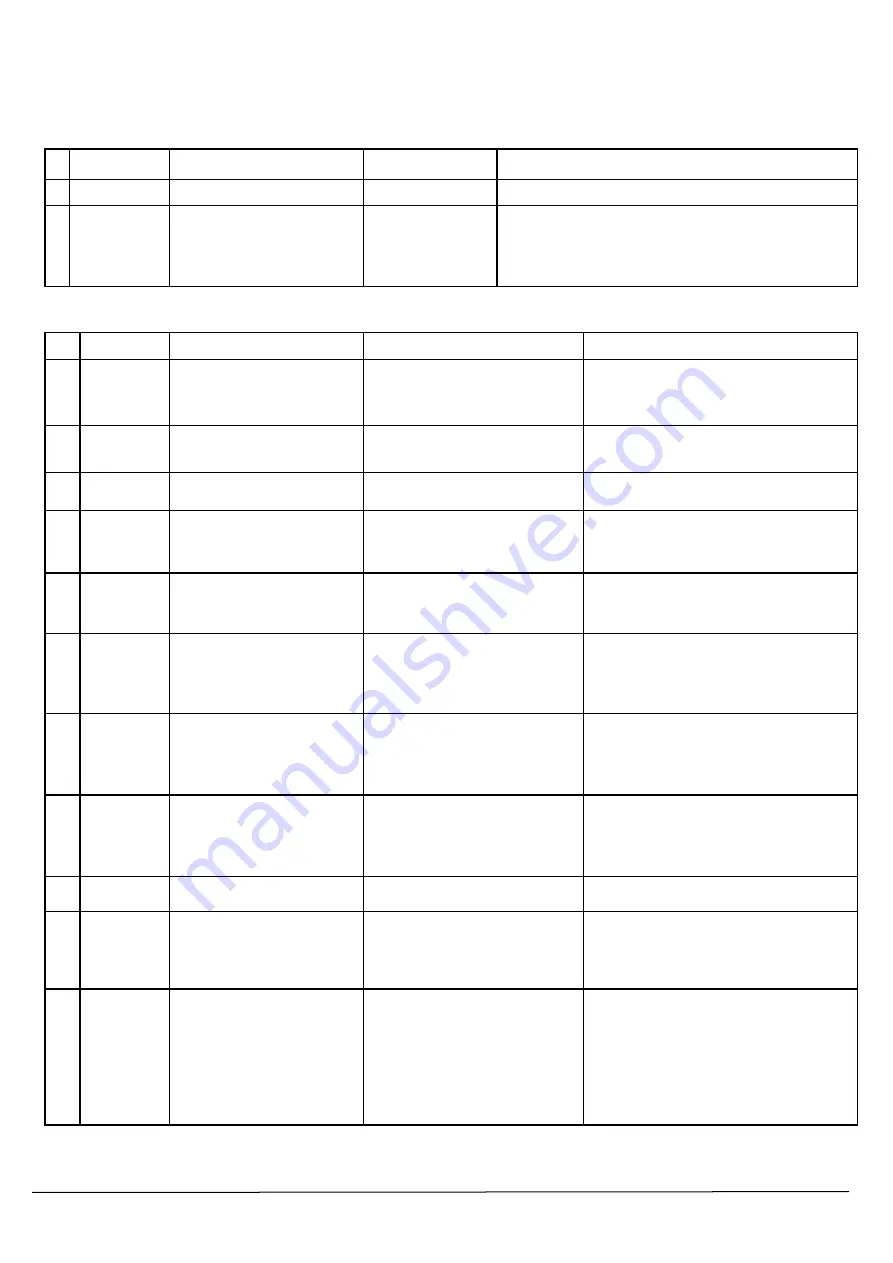

6-13 ERROR MESSAGE

NO

REFERENCE

1

Refer to Service Call

2

6-14 SERVICE CALL

MEANING

ACTION

Sub CPU

Communication

Error

1) Check Cable Connection between Main Board

and Servo Board

2) Servo Board Replacement

3) Main Board Replacement

DIPSW model

setting error

1) Check the DIPSW setup

2) Replacement the Main Board

Limit Position

Error

1) Carry out Limit Position Initialize.

Head Lock

Sensor Error

1) Head Lock Sensor Replacement

2) Check the mechanical Backlash or loose with

the scanning axes.

Limit Sensor

Error

1) Limit Sensor Replacement

2) Check the mechanical Backlash or loose with

the scanning axes.

Cap Unit

Protection Error

1) Cap Motor Replacement

2) Cap Unit Replacement

3) Cap Sensor Replacement

4) Cable and Flexible Cable Replacement

Tool Carriage

Connection

Error

1) Check the mechanical Backlash or loose with

the Tool Carriage part.

2) Lock Position Adjustment

3) Limit Position and Cut Down Position Initialize

4) Limit Sensor Replacement

Tool Carriage

Disconnection

Error

1) Check the mechanical Backlash or loose with

the Tool Carriage part.

2) Lock Position Adjustment

3) Limit Position and Cut Down Position Initialize

4) Limit Sensor Replacement

Unset up of the

Linear Encoder

1) Carry out Linear Encoder Setup.

Wiper

Protection Error

1) Wiper Origin Motor Replacement

2) Wiper Unit Replacement

3) Wiper Origin Sensor Replacement

4) Cable and Flexible Cable Replacement

Linear Encoder

Error

1) Confirm whether Encoder Scale is between the

slit of Encoder Module in a whole width of the

machine.

2) Linear Encoder Replacement

3) Scan Motor Replacement

4) Confirm Cable Connection between Linear

Encoder Board and Print Carriage Board.

5) Confirm Connection between Wire and Head

Carriage.

0002

0101

0102

0103

0104

0105

0106

0107

Machine fails to connect the Tool

Carriage to the Head Carriage.

Machine fails to disconnect the

Tool Carriage from the Head

Carriage.

0109

0110

Linear Encoder Setup has not

been done.

Even though the machine carries

out the regular movement, the

output of the Wiper Origin Sensor

does not reach the expected value.

Input value from Linear Encoder is

not changed when Linear Encoder

is set up the Origin.

When Motor stops during printing,

Motor does not complete the

movement which is supposed to be

done.

Limit Position Initialize has not

been done.

Even though the machine carries

out the regular movement, the

output of the Head Lock Sensor

does not reach the expected value.

Even though the machine carries

out the regular movement, the

output of the Limit Sensor does not

reach the expected value.

Even though the machine carries

out the regular movement, the

output of Cap Sensor does not

reach the expected value.

CAUSE

Sub Board does not work correctly.

Sub CPU does not work correctly.

There is a bad connection between

Main Board and Sub Board.

Limit Position Initialize has not been

done.

Head Lock Sensor does not work

correctly or is broken.

Limit Sensor does not work correctly or

is broken.

Disorder of Cap Motor

Fault of Cap Unit

Fault of Cap Sensor

Cut-line or short-circuit of Cable and

Flexible Cable

Fault of Tool Carriage Connection

Loose of Connection Part

Fault of the Limit Position Initialize value

Limit Sensor does not work correctly or

is broken.

CONTENTS

Disorder of communication with

Sub CPU

Disorder of Wiper Origin Sensor

Fault of Wiper Unit

Fault of Wiper Origin Sensor

Cut-line or short-circuit of Cable and

Flexible Cable

Read error of Linear Encoder

Read error of Encoder on Scan Motor

side

Wire is not fixed to Head Carriage firmly.

OUTLINE

This message is displayed when an unexpected error happens.

In the most case, the error can be fixed by restarting the machine.

If the error still happens in spite of restarting the machine, it

sometimes could be solved by carrying out the Limit Initialization

or changing some setting values.

Disorder of Cap Motor

Loose of Connection Part

Fault of the Limit Position Initialize value

Limit Sensor does not work correctly or

is broken.

Linear Encoder Setup has not been

done.

0003

A setup about the model of DIPSW

is set up in an unsuitable

combination.

DIPSW setup error

DIPSW defect

Main Board defect

ACTION

CHECKING

POINT

Restart machine

Internal Error

Refer to Service Call

Service Call

CODE

No.

6-10

Summary of Contents for VersaCamm SP-540V

Page 31: ...2 10 2 3 SERVO BOARD ...

Page 32: ...2 11 ...

Page 37: ...2 16 2 4 HEATER BOARD ...

Page 40: ...2 19 2 5 SUB BOARD ...

Page 88: ...3 43 9 Carry out the LINEAR ENCODER SETUP ...

Page 150: ...4 53 4 9 Check and make sure that the tension is within the range If not adjust it again ...