4-4

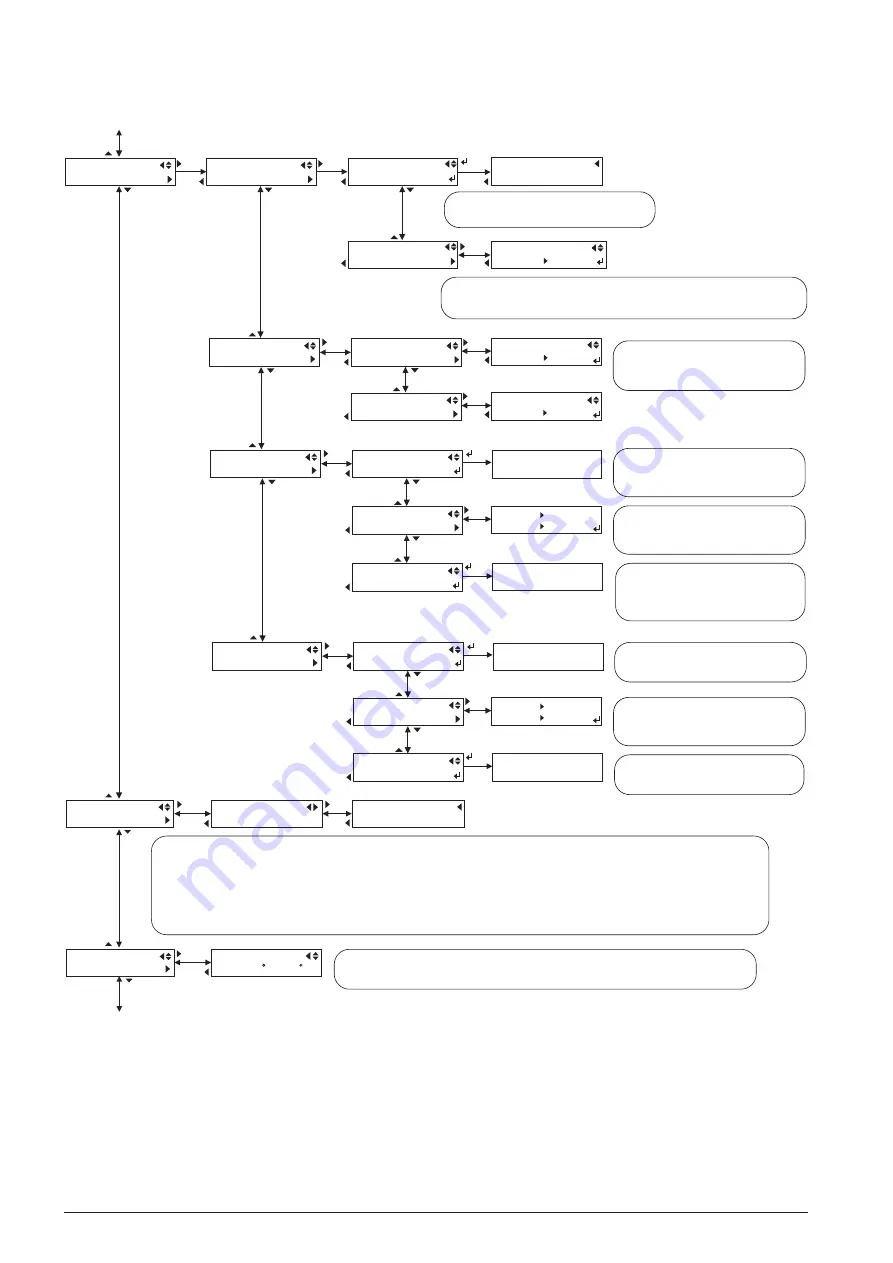

CUTTING MENU

FORCE ADJUST

FORCE ADJUST

30gf

30gf

17 16

CUTTING MENU

CROPMARK SENSE

CROPMARK SENSE

OUTLEVEL CHECK

SERVICE MENU

CUTTING MENU

CROPMARK SENSE

ADJUST

ADJUST

+2 +1

FORCE ADJUST

200gf

200gf

56 57

CUTTING MENU

CROP-CUT ADJ.

CROP-CUT ADJ.

TEST PRINT

CROP-CUT ADJ.

SETTING

S:-0.40 -0.40mm

CROP-CUT ADJ.

TEST PRINT 2

PERFORMING

PERFORMING

CUTTING MENU

PRINT-CUT ADJ.

PRINT-CUT ADJ.

TEST PRINT

PRINT-CUT ADJ.

SETTING

PRINT-CUT ADJ.

TEST PRINT 2

PERFORMING

PERFORMING

MIN 0.7V MAX2.3

[2.0V ]

F:+0.30 +0.30mm

S:-0.40 -0.40mm

F:+0.30 +0.30mm

SERVICE MENU

SENSOR CHECK

FRSHODPULWwab

*** H *

1234

*EC

SERVICE MENU

THERMISTOR CHK

THERMISTOR CHK

HEAD:25 C/ 77 F

This is for adjusting the level of Crop Mark Sensor.

Refer to [4-8 CROP MARK SENSOR ADJUSTMENT].

This is for adjusting the Crop Mark Sensor sensitivity. There are 3 levels of sensitivity, 0, +1 and +2.

This adjustment may help when Crop Mark detection is failed with the default level setting.

Default: 0

TEST PRINT

TEST PRINT

Returns to menu with [MENU] key

TEST PRINT

TEST PRINT

Returns to menu with [MENU] key

This is for adjusting the Tool Pressure.

Refer to [4-13 TOOL PRESSURE ADJUSTMENT].

30gf Range: 0 to 30 Default: 17

200gf Range: 31 to 80 Default: 56

This test pattern is for adjusting the cut position

during automatic Crop Mark detection. It prints a

square Crop Mark and cuts the contour after

detecting the mark.

When it shows [ ], it means that it has never

been setup and it needs to be set. In this case, even

if adjustment is unnessesary due to the test result,

[0] must be set here.

This test pattern is for adjusting the cut position

during automatic Crop Mark detection. It prints a

square Crop Mark and continuously prints 0.1mm

scales for both scan and feed direction, and then

cuts crosswise after detecting the mark.

This test pattern is for adjusting the print & cut

position. It prints 3 square Crop Marks along the

scan direction and cuts the contours of the marks.

When it shows [ ], it means that it has never

been setup and it needs to be set. In this case, even

if adjustment is unnessesary due to the test result,

[0] must be set here.

This test pattern is for adjusting the print & cut

position. It prints 0.1mm scales for both scan and

feed direction and then cuts crosswise.

This menu displays the real-time status of each sensor. It shows [ ] when the sensor is ON.

The first page shows the status of each sensor. Each alphabet stands for as follows.

F: Front Paper Sensor

R: Rear Paper Sensor

S: Crop Mark Sensor

H: Head Lock Sensor

O: Limit Sensor

D: Side Cover Sensor

P: Maintenance Cover Sensor

U: Head Up/Down Sensor

L: Sheet Load Sensor

W: Pinch Roller Sensor

w: Wiper Sensor

a: TU Motor Drive Sensor

(When TU is connected)

b: Not in use

Head Up/Down Sensor (VP-300: Fixed)

H: Head HIGH

L: Head LOW

TU Motor Drive Sensor

: Driving

Blank: Not driving

The second page shows the status of each

Cartridge Sensor and Ink Empty Sensor.

Each color has 2 positions and the left side

on the display shows the left-side head.

Blank: Cartridge not inserted, Ink remains

C: Cartridge inserted, Ink remains

E: Cartridge not inserted, Ink empty

: Cartridge inserted, Ink empty

This is for checking Thermistor. It displays the temperature read from the thermistor placed on the board of the Head1.

The temperature on the left is in Celsius and the right is in Fahrenheit.

Since the temperature of the device possibly rises, it normally shows higher temperature than the room temperature.

*****

*****

*

*

*