3-19

13

14

Perform the following adjustments and settings.

1. [4-5 LIMIT POSITION & CUT DOWN POSITION INITIALIZE]

2. [4-7 FLUSHING POSITION ADJUSTMENT]

3. [4-12 TOOL HEIGHT ADJUSTMENT]

4. [4-13 TOOL PRESSURE ADJUSTMENT]

5. [4-8 CROP MARK SENSOR ADJUSTMENT]

6. [4-9 CROP-CUT ADJUSTMENT]

7. [4-10 PRINT / CUT POSITION ADJUSTMENT]

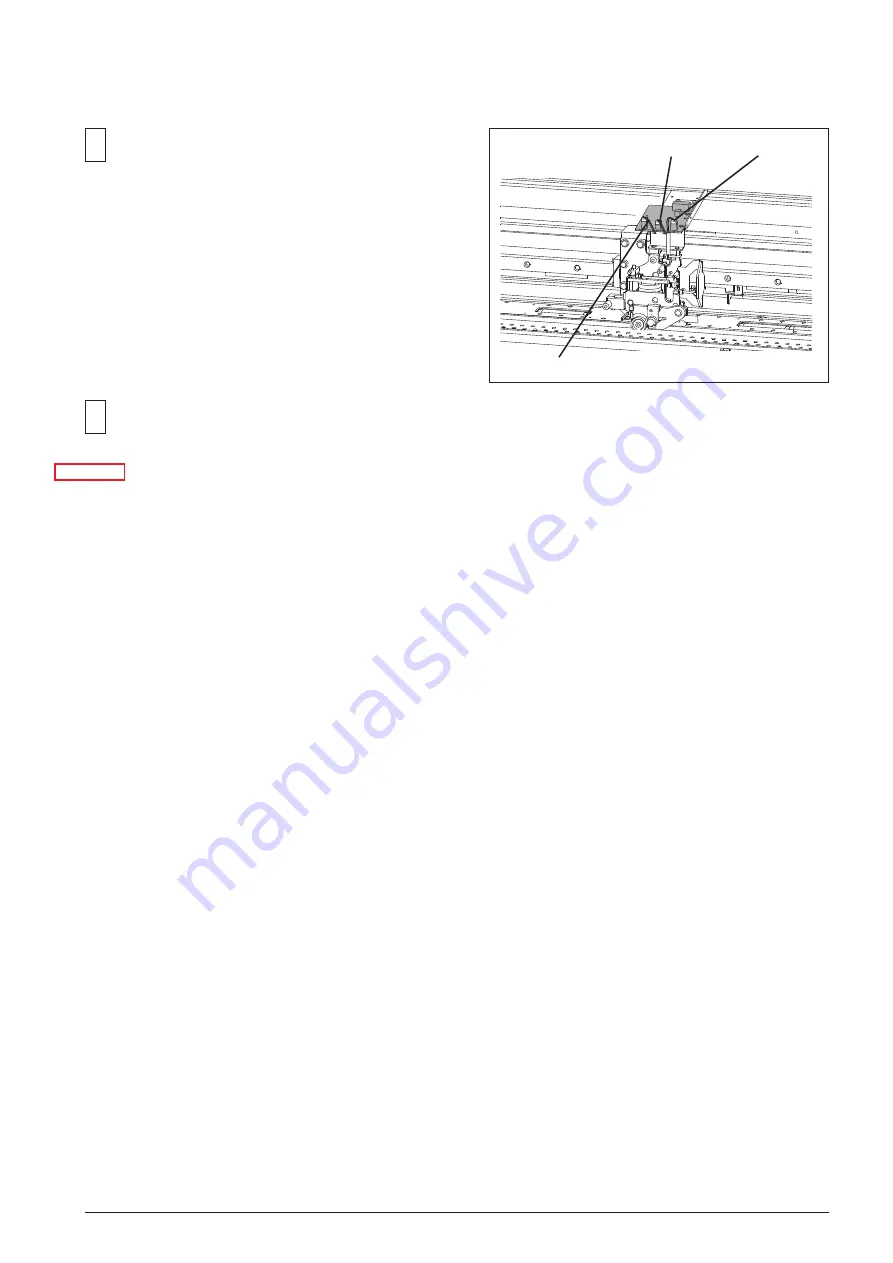

Connect the Crop Mark Sensor, Pinch Roller Sensor and

Solenoid wirings.

CROP MARK SENSOR

SOLENOID

PINCH ROLLER SENSOR

Revised 1