4-3

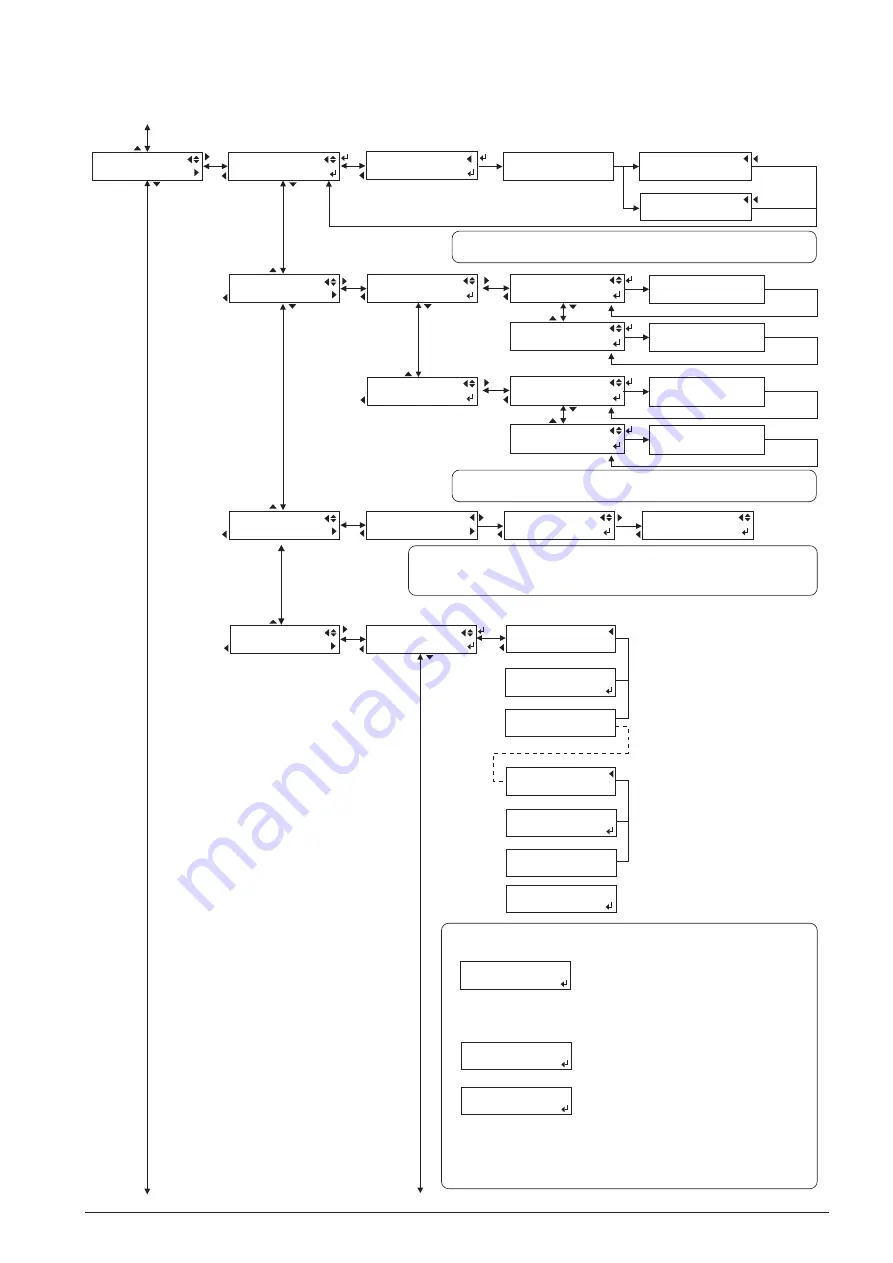

I/S MENU

I/S CHECK

NOW PROCESSING..

I/S CHECK ERROR

WIPER

SERVICE MENU

I/S MENU

I/S MENU

PUMP CHECK

PUMP CHECK

PUMP SUCTION

NOW PROCESSING..

NOW PROCESSING..

NOW PROCESSING..

NOW PROCESSING..

I/S CHECK

COMPLETED

PUMP CHECK

PUMP RELEASE

I/S MENU

I/S CONTROL

I/S CONTROL

WIPER/FELT

MOVE CARRIAGE

TO AVOID WIPER

WIPER/FELT

ORIGIN

Checking

The wiper can be moved manually.

Option: ORIGIN / WIPER / FELT / FELT WAITING

Default: ORIGIN

Caution: Make sure not to have the Head Carriage and Tool carriage above the wiper unit during this operation.

Error

This is for checking the pump motor. The rotation for both ink suction and release can be checked.

Pump motor rotates for 5 seconds and stop.

This is for checking the operation of the wiper motor and sensor.

Make sure not to have the Head Carriage and Tool Carriage above the wiper unit during the check.

MOVE CARRIAGE

TO AVOID WIPER

PUMP SUCTION

A

PUMP SUCTION

CIR-PUMP

PUMP RELEASE

A

PUMP RELEASE

CIR-PUMP

I/S MENU

CARTRIDGE

CARTRIDGE

IC CHECK

IC CHECK

SLOT1 INSERT

IC CHECK

SLOT1 ERROR

Error

IC CHECK

SLOT1 OK

Normal

Set cartridge to SLOT1

IC CHECK

SLOT8 INSERT

IC CHECK

SLOT8 ERROR

Error

IC CHECK

SLOT8 OK

Normal

Set cartridge to SLOT12

From SLOT1 to 8 in order

IC CHECK

COMPLETED

IC CHECK

SYSTEM ERROR

IC CHECK

COMPLETED

IC CHECK

SLOT1 ERROR

Remove all cartridges

before pressing [ENTER] key

All cartridges must be removed before entering IC HECK menu.

It detects Ink Cartridge IC, writes and loads information, and checks the communication. First, it confirms

if there is the driver for IC detection. The message below is shown when an error is found on the driver.

Next, IC communication is checked individually by slot.

When a cartridge is inserted, it automatically starts to communicate with the cartridge IC for checking. Display

shows [OK], when the communication is done properly. As cartridge is removed, the slot number of next

cartridge to be inserted is displayed. Starting from SLOT1, it continues to SLOT8 in order. When the check

of SLOT8 is completed, the following message is displayed at the end of check.

It returns to IC CHECK menu by pressing [ENTER] key. When communication is failed, it displays as below.

It returns to IC CHECK menu by pressing [ENTER] key.

NOTE:

Any cartridge can be used for this check as long as it has IC chip on it.

No information is written on IC chip during this check. (Normally, the count of the cartridge installation is

written. However, the count of the installation in this check is not written.)

Before this IC CHECK, make sure Cartridge Sensor is working properly.

Summary of Contents for VS-300

Page 49: ...2 4 MAIN BOARD_Arrangement Diagram Soldering Side ...

Page 60: ...2 15 SERVO BOARD_Arrangement Diagram Soldering Side ...

Page 65: ...2 20 2 4 CARRIAGE BOARD CARRIAGE BOARD_Arrangement Diagram Component Side ...

Page 68: ...2 23 2 5 SUB BOARD SUB BOARD_Arrangement Diagram Component Side ...