4-4

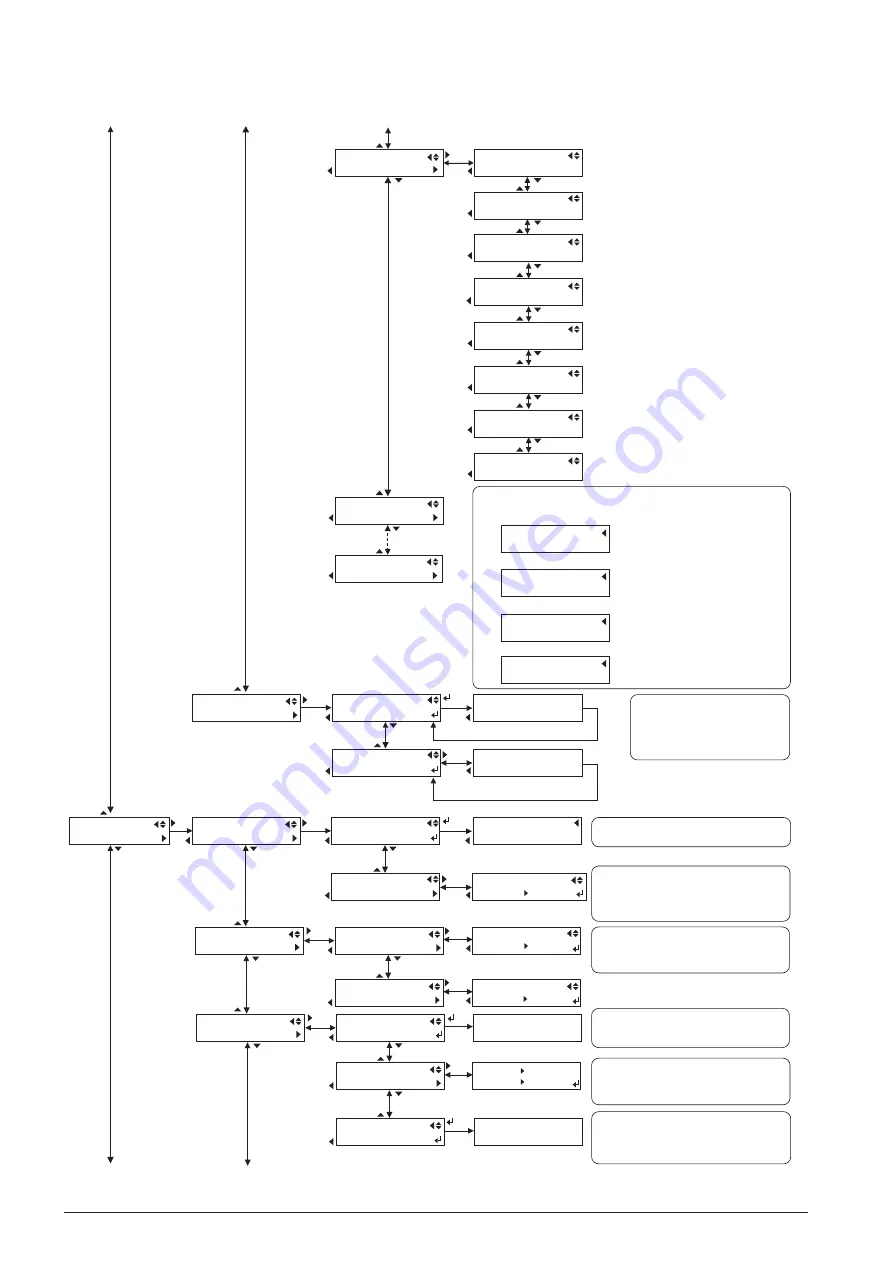

CARTRIDGE

SLOT 1

SL1 : CAPACITY

200cc

SL1 : CONSUM.

100.000cc

SL1 : TIME

0y000d00h00m00s

CARTRIDGE

SLOT 2

SL1 : SERIAL

1402A30C010000A5

SL1 : INK TYPE

Max K

SL1 : LOT NO.

40216A

SL1 : INSERT

1 times

SL1 : FLAG

000000000

Serial No. of the Ink Cartridge IC is displayed.

Ink type of the Ink Cartridge IC is displayed.

Ink capacity of the Ink Cartridge IC is displayed.

Lot No. of the Ink Cartridge IC is displayed.

Ink consumption of the Ink Cartridge is displayed.

The used time of the Ink Cartridge is displayed.

The insert count of the Ink Cartridge is displayed.

The Flag information of the Ink Cartridge is displayed.

It reads the information written on the IC of each carriage.

Following messages are displayed when some error is found.

Ink cartridge is not inserted

System error due to the trouble such as a damage of driver IC placed on Ink Tank Board

Data error

CARTRIDGE

SLOT 8

SLOT1

NO CARTRIDGE

SLOT1

NO IC CHIP

SLOT1

SYSTEM ERROR

SLOT1

DATA ERROR

A cartridge with no IC is inserted, wire break or short

I/S MENU

CIRCULATE INK

CIRCULATE INK

CIRCULATION

CIRCULATE INK

CIR-DISCHARGE

CIRCULATING INK

CIRCULATING INK

CUTTING MENU

FORCE ADJUST

FORCE ADJUST

30gf

30gf

17 16

CUTTING MENU

CROPMARK SENSE

CROPMARK SENSE

OUTLEVEL CHECK

SERVICE MENU

CUTTING MENU

CROPMARK SENSE

ADJUST

ADJUST

+2 +1

FORCE ADJUST

200gf

200gf

56 57

CUTTING MENU

CROP-CUT ADJ.

CROP-CUT ADJ.

TEST PRINT

CROP-CUT ADJ.

SETTING

S:-0.40 -0.40mm

CROP-CUT ADJ.

TEST PRINT 2

PERFORMING

PERFORMING

MIN 0.7V MAX2.3

[2.0V ]

F:+0.30 +0.30mm

This is for adjusting the level of Crop Mark Sensor.

Refer to [4-7 CROP MARK SENSOR ADJUSTMENT].

This is for adjusting the Crop Mark Sensor sensitivity.

There are 3 levels of sensitivity, 0, +1 and +2.

This adjustment may help when Crop Mark detection is

failed with the default level setting.

Default: 0

TEST PRINT

TEST PRINT

Returns to menu with [MENU] key

This is for adjusting the Tool Pressure.

Refer to [4-12 TOOL PRESSURE ADJUSTMENT].

30gf Range: 0 to 30 Default: 17

200gf Range: 31 to 80 Default: 56

This test pattern is for adjusting the cut position during

automatic Crop Mark detection. It prints a square

Crop Mark and cuts the contour after detecting the mark.

When it shows [ ], it means that it has never

been setup and it needs to be set. In this case, even

if adjustment is unnessesary due to the test result,

[0] must be set here.

This test pattern is for adjusting the cut position during

automatic Crop Mark detection. It prints a square

Crop Mark and continuously prints 0.1mm scales for

both scan and feed direction, and then cuts crosswise

after detecting the mark.

*****

This menu is to circulate the white ink.

CIRCULATION : Circulate ink.

CIR-DISCHARGE : Circulate ink and

discharge the determinate quantity of ink.

Summary of Contents for VS-300

Page 49: ...2 4 MAIN BOARD_Arrangement Diagram Soldering Side ...

Page 60: ...2 15 SERVO BOARD_Arrangement Diagram Soldering Side ...

Page 65: ...2 20 2 4 CARRIAGE BOARD CARRIAGE BOARD_Arrangement Diagram Component Side ...

Page 68: ...2 23 2 5 SUB BOARD SUB BOARD_Arrangement Diagram Component Side ...