4-42

2

3

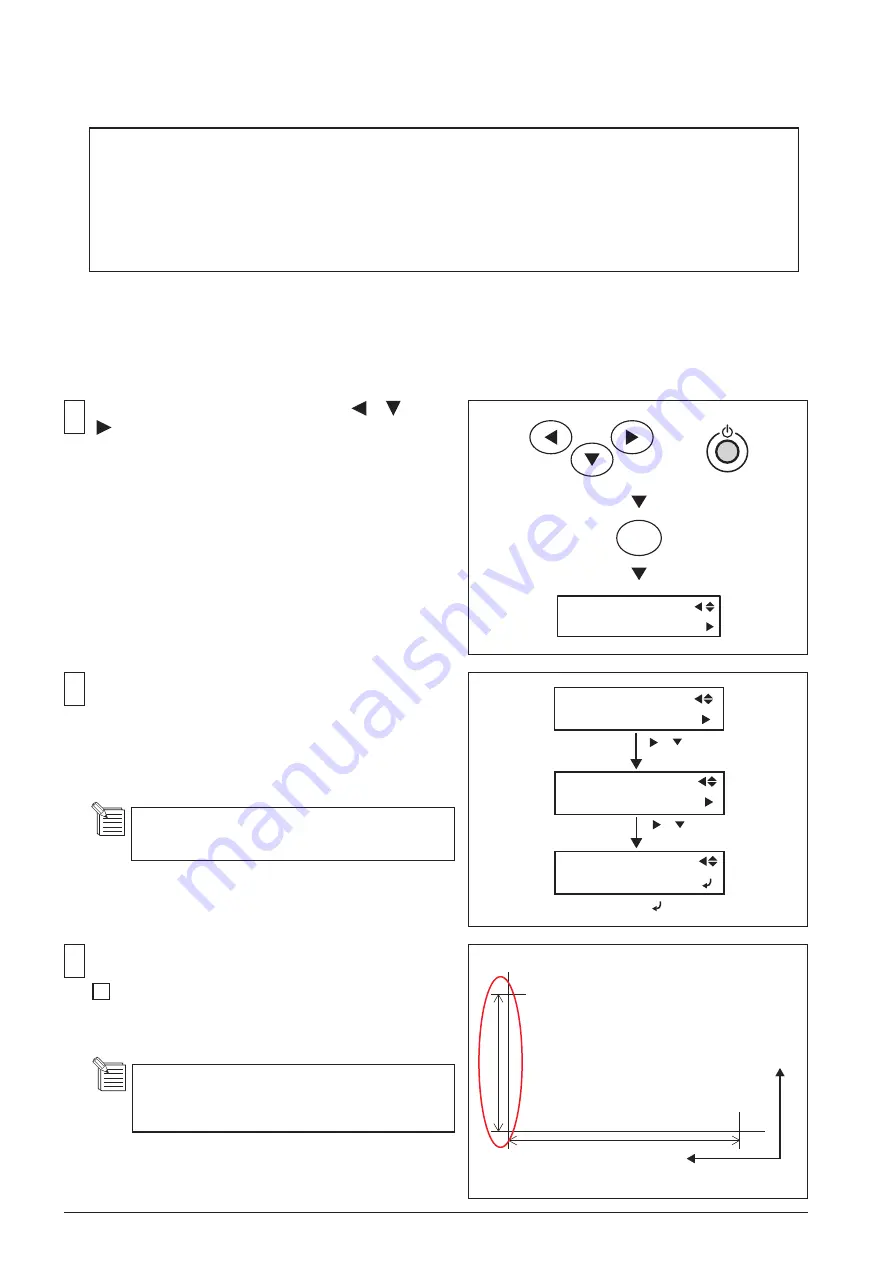

4-10 CALIBRATION (FEEDING DIRECTION) (Referential Time : 20 min.)

This adjustment is for calibrating the feed amount of media. It allows the media to be fed proper amount by calibrat-

ing the variation in Grit Roller diameter. Calibration is made based on the value in feeding media [PET-G].

Without proper calibration, it may cause misalignment in the feed amount of media, and it results in the problems

such as white banding, banding of overlap or the dimension error of print result compared to the original data.

Take-up Unit must not be used during this adjustment.

Select [PRINT MENU]>[CALIB.DEFAULT]>[TEST PRINT],

and press [ENTER] key.

Test Pattern will be printed.

Test print requires 510mm or more of the media

setup width.

Measure the length of the feed direction and use the value to

calculate the calibration amount with the formula shown at

4 .

Test pattern is always printed with offset 0.00%.

Even if a correction is made in the [SETTING]

menu, the test pattern is not changed.

Turn on the Sub Power SW while pressing [ ], [ ] and

[ ] keys to enter the Service Mode.

Setup the PET-G on the machine.

1

[ ]

SERVICE MENU

PRINT MENU

CALIB.DEFAULT

TEST PRINT

PRINT MENU

CALIB.DEFAULT

[ ]

[ ]

[ ]

[ ]

Scan

F

eed

500mm

400mm

MENU

SERVICE MENU

+

MENU

Summary of Contents for VS-300

Page 49: ...2 4 MAIN BOARD_Arrangement Diagram Soldering Side ...

Page 60: ...2 15 SERVO BOARD_Arrangement Diagram Soldering Side ...

Page 65: ...2 20 2 4 CARRIAGE BOARD CARRIAGE BOARD_Arrangement Diagram Component Side ...

Page 68: ...2 23 2 5 SUB BOARD SUB BOARD_Arrangement Diagram Component Side ...