6 Troubleshooting

6-1 WHITE FINE LINE / BANDING / MISSING DOT / SCRATCHY PRINTING / BLURRED PRINTING

NO

CHECK

ACTION

REFERENCE

OUTLINE

1

The machine is not

installed in an appropriate

location

Install in a location that is

level and stable offering

good operating conditions

Never install the machine in a location where it is tilted or where

it may wobble or librate.

2

The media is not set up

correctly

Load and set up the media

at the correct position

User's Manual

Feed is not smooth when the media is tilted or tensioned

unevenly on the left or right. Reload and set up the media

correctly.

3

Temperature of the Print

heater / Dryer is

inappropriate

Set appropriate

temperature

User's Manual

When the temperature of the print heater is too high and the ink

dries too fast, it may result in banding because the dots stay

small after landing on media.

When the temperature of the print heater is too low and the ink

dries too slow, it may result in black banding because the dots

stay large and overlap each other after landing on media.

4

The media is not

appropriate

Use other media

The substrate which stretches or shrinks considerably or the

one which does not absorb the ink efficiently cannot be used.

5

Bi-directional adjustment is

not correct

Correct the setting for

Bidirectional Printing

User's Manual

6

FEED CALIBRATION is

not correct

Correct Calibration

User's Manual

If the calibration is not correct, white fine line caused by gaps or

dark line caused by overlapping appears.

7

Scanning distance of the

Head Carriage

Set the [FULL WIDTH S]

to [FULL]

User's Manual

Set [FULL WIDTH S] to [FULL] to equalize the heating time on

each pass. This may improve printing quality.

8

[PERIODIC CL.] setting

Set [PERIODIC CL.] to

[NONE] or [Page]

User's Manual

When this is set to [1 min] to [990 min], self cleaning is

performed while printing is paused. And it may cause uneven

printing before and after cleaning.

9

Wrong profile for the

media

Use the suitable profile

10

Head Rank is not correct

Set Head Rank

[3-1 HEAD

REPLACEMENT]

Head Rank setting affects the amount of the ink fired. If it is not

set properly, the ink dots are not fired in appropriate sizes.

11

Head is not adjusted

Adjust Head

[4-3 HEAD

ADJUSTMENT]

Check whether [BIAS] setting is correct.

12

Ink tubes are not bundled

correctly

Correct the order of ink

tubes in the saddles

[3-20 INK TUBE

REPLACEMENT]

Ink tubes incorrectly bundled in the saddles pull the print head

upward, that may tilt the print head.

13

Ink agitation in the ink

cartridge

Shake the cartridges

gently

User's Manual

The message to shake the cartridges is displayed periodically. If

you do not follow the message, the ink generates high or low

density inside to bring about inappropriate printing result.

14

Defect of Cap Top

Replace Cap Top

[3-5 CAP TOP

REPLACEMENT]

Cleaning does not work effectively and the nozzle condition

cannot be improved. Also, if the head is not capped correctly,

the head dries and it may cause the nozzle clog.

15

Air inside the ink damper

Perform [CHOKE CL]

[3-2 DAMPER

REPLACEMENT]

If the ink damper has the air inside, the ink is supplied

intermittently. Therefore, it causes missing dots or deflected

dots.

16

Foreign substances

Perform Manual Cleaning

User's Manual

Nozzle condition becomes poor due to the foreign substances

stuck on the surface of the Head.

6-1

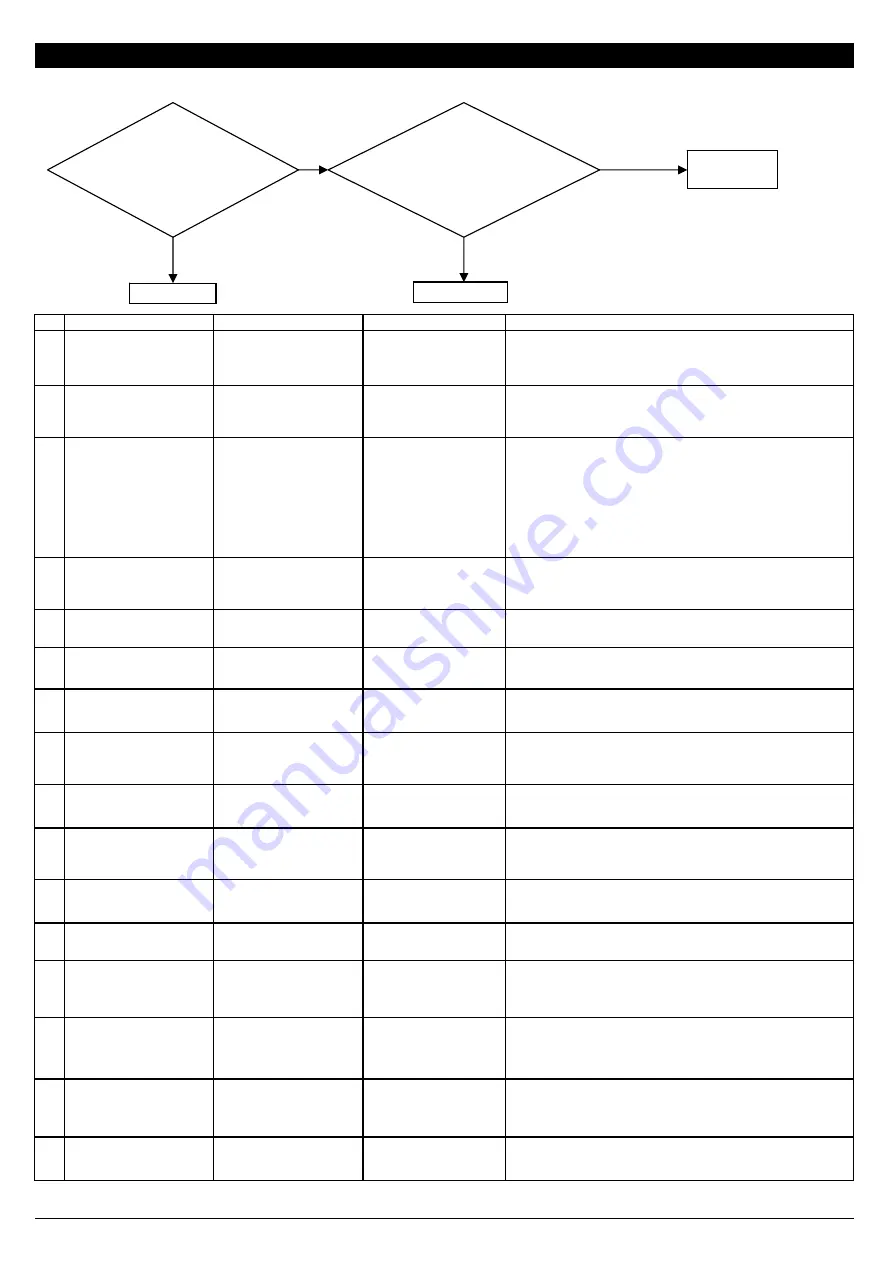

Missing dot or

deflected-fired dot

appears on the test

pattern.

Perform Normal

Cleaning

Go to 14 to 23

Go to 1 to 13

Yes

Not Improved

*Several Normal Cleanings and a Powerful Cleaning did not

improve the printing result.

No

Completed

Improved

Summary of Contents for VS-300

Page 49: ...2 4 MAIN BOARD_Arrangement Diagram Soldering Side ...

Page 60: ...2 15 SERVO BOARD_Arrangement Diagram Soldering Side ...

Page 65: ...2 20 2 4 CARRIAGE BOARD CARRIAGE BOARD_Arrangement Diagram Component Side ...

Page 68: ...2 23 2 5 SUB BOARD SUB BOARD_Arrangement Diagram Component Side ...