eng eng

● Observe safety tips for refrigeration systems. There is a risk of injury.

● Dispose of the apparatus and the refrigerant properly. Observe the national

regulations.

● Refrigerant may not be allowed to get into sewers, basements or work pits.

Refrigerant vapours may create a suffocating atmosphere.

● Do not insert any objects into the apparatus. There is a danger of injury and

a risk of electric shock.

● Do not place any objects on the apparatus. Vibration of the apparatus can

cause the objects to fall off. The objects could be damaged. There is a risk of

injury.

● When installing the device, ensure adequate ventilation and the permissible

minimum room size of 9 m

2

for ROLLER’S Scirocco 50 and 14 m

2

for

ROLLER’S Scirocco 80 and a minimum distance of approx. 200 mm from

the wall. Never cover up the air vents of the apparatus. This can reduce the

performance. The apparatus can overheat. There is a danger of fire.

● Do not use the apparatus in air-tight rooms. The apparatus can overheat.

There is a danger of fire.

● Do not use highly inflammable materials e. g. gases, oils as well as aerosol

cans with propellant gas, e.g. thread cutting oil, paints in the vicinity of the

apparatus. The device could be damaged. There is a danger of fire.

● Never place the device in flooded rooms. Never lay the power cable and

extension leads on a damp or wet surface. There is a danger of electric shock.

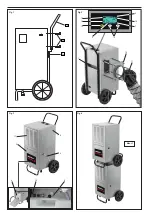

● Always stand the apparatus properly upright on the wheels, even during

storage and transport. The apparatus could otherwise be damaged.

● Do not use the collected condensation (water) as drinking water or for

preparing meals. There is a risk to your health.

● Do not use the device if it is damaged. There is a danger of accident.

●

Check the proper drainage of the condensation regularly. Switch off the

device during longer work breaks, pull out the mains plug and remove all

hoses. Electrical devices can cause hazards which lead to material damage or

injury when left unattended.

● Children and persons who, due to their physical, sensory or mental abilities

or lack of experience and knowledge are unable to operate the electrical

device safely may not use this electrical device without supervision or

instruction by a responsible person. Otherwise there is a risk of operating

errors and injuries.

● Only allow trained persons to use the electrical device. Apprentices may

only operate the electrical device when they are older than 16, when this is

necessary for their training and under the supervision of a trained operative.

● Check the power cable of the electrical device and the extension leads

regularly for damage. Have these renewed by qualified experts or an authorised

ROLLER customer service workshop in case of damage.

● Only use approved and appropriately marked extension leads with a suffi-

cient cable cross-section. Use extension leads up to a length of 10 m with

cable cross-section 1.5 mm², from 10 – 30 m with cable cross-section 2.5 mm².

Explanation of symbols

WARNING

WARNING

Danger with a medium degree of risk which could result in

death or severe injury (irreversible) if not heeded.

CAUTION

CAUTION

Danger with a low degree of risk which could result in minor

injury (reversible) if not heeded.

NOTICE

NOTICE

Material damage, no safety note! No danger of injury.

Warning against inflammable materials

See the operating manual

Instructions for use; operating instructions

Service display; consult the operating manual

Use hand protection

Power tool complies with protection class I

Environmentally friendly disposal

CE conformity mark

Not suitable for using outdoors

1. Technical Data

Use for the intended purpose

WARNING

WARNING

The

ROLLER’S Scirocco 50 and ROLLER’S Scirocco 80 electric air dehumidifiers/

building driers are intended for drying and dehumidifying rooms, e.g. after mains

water damage, flooding, dehumidification of damp cellar rooms etc. and for fast

drying of concrete, masonry, plaster and screed for example. The operating hours

counter and electricity meter is intended for recording the operating hours and

electricity consumption when drying and dehumidifying with

ROLLER’S Scirocco

50. For commercial use in trade and industry. All other uses are not for the intended

purpose and are therefore prohibited.

1.1. Scope of Supply

ROLLER’S Scirocco 50, 7.7 l condensation tank, condensation draining hose,

operating instructions.

ROLLER’S Scirocco 80, operating instructions.

1.2. Article numbers

ROLLER’S Scirocco 50 Set

132011

ROLLER’S Scirocco 80 Set

132010

11.5 l condensation tank Scirocco 80 132100

Connecting flange Scirocco 80 132101

Exhaust air hose Ø 200 mm, 10 m long, Scirocco 80 132102

Exhaust air set Scirocco 80 (connecting flange,

exhaust air hose Ø 200 mm)

132104

Condensation tank with pump Scirocco 50

132129

Condensation tank with pump Scirocco 80

132121

Operating hours counter and electricity meter

132132

ROLLER’S Control W, dielectric humidity meter

132115

Machine cleaner

140119

1.3. Applications

Scirocco 50

Scirocco 80

Dehumidification rate

≤ 50 l/24 h

≤ 80 l / 24 h

Air volume

≤ 233 m

3

/h

≤ 850 m

3

/h

Adjustment range of

the relative humidity

30 – 90 %

30 – 90 %

Compressor

Rotation piston compressor Rotation piston compressor

Ambient temperature

+5 °C – +32 °C

+5 °C – +32 °C

(41 °F – 89 °F)

(41 °F – 89 °F)

Storage temperature

+5° C – +45 °C

+5° C – +45 °C

(41 °F – 113 °F)

(41 °F – 113 °F)

1.4. Electrical data

See the rating plate!

Dehumidifier/building dryer with R-410A / R-407C refrigerant

220 – 240 V~; 50 Hz

220 – 240 V~; 50 Hz

900 W; 4.1 A

1200 W; 5.3 A

Protection class I

Protection class I

Dehumidifier/building dryer with R-290 refrigerant

220 – 240 V~; 50 Hz

220 – 240 V~; 50 Hz

760 W; 3.5 A

680 W; 3.0 A

Protection class I

Protection class I

Condensation tank with pump

100 – 240 V~; 50 – 60 Hz 100 – 240 V~; 50 – 60 Hz

12 V –

---

12 V –

---

Operating hours counter and electricity meter

230 V~; 50 Hz

≤ 3680 W

Protection class I

Protection class IP20

4,5 V –

---

1.5. Coolant data

See the rating plate!

Coolant

R-410A R-407C

GWP

2088

1774

CO

2

comp.

0,6682 t

1,455 t

Filling quantity

0.320 kg

0.820 kg

Operating pressure low pressure side ≤ 18 bar

≤ 10 bar

Operating pressure high pressure side ≤ 36 bar

≤ 25 bar

Coolant

R-290 R-290

GWP

3

3

CO

2

comp.

0.0006 t

0.0009 t

Filling quantity

0.182 kg

0.300 kg

Operating pressure low pressure side ≤ 12 bar

≤ 10 bar

Operating pressure high pressure side ≤ 24 bar

≤ 22 bar

1.6. Dimensions L × W × H

385 × 320 × 595 mm

540 × 530 × 1 040 mm

(15,2" × 12,6" × 23,4")

(21,3" × 20,9" × 40,9")

12