5. Faults

5.1. Fault: Device does not start.

Cause:

Remedy:

● Power cable defective.

● Have the power cable replaced by qualified personnel or an authorised

ROLLER customer service workshop (

ROLLER’S Scirocco 50). Replace

power cable. (

ROLLER’S Scirocco 80).

● Device defective.

● Have the apparatus checked/repaired by an authorised ROLLER customer

service workshop.

● The humidity set on the device is higher than the humidity in the room.

● No dehumidification necessary or correct the humidity setting on the device,

see 3. Operation

● ROLLER’S Scirocco 50: The condensation tank (9) is not pushed in

completely.

● Push in the condensation tank as far as it will go.

●

ROLLER’S Scirocco 80: 11.5 l condensation tank (9) (accessory, Art. No.

132100) was inserted incorrectly in the

ROLLER’S Scirocco 80.

● See 2.4.

2

●

ROLLER’S Scirocco 80: Condensation tank switch set incorrectly (5).

● See 2.3.

2 and 2.4.2

5.2. Fault: On reaching the humidity set on the device, the device does not switch on or off.

Cause:

Remedy:

● The controller only switches the device on/off when the humidity exceeds/

drops below the set humidity by 3 % (

ROLLER’S Scirocco 80).

● Wait or correct the humidity setting on the device, see 3.

● Continuous operation is set.

● Change the operating mode, see 3.

3.2. Switch on the

ROLLER’S Scirocco 80 with the On/Off button (13). All the

symbols are shown briefly in the display (2), then the currently measured

relative humidity (14). The device is pre-set to 60 % relative humidity. Set the

desired humidity between 30 and 90 % with the two buttons (15). Briefly pressing

the buttons changes the value by 1 %; keep the button pressed for longer for

fast adjustment. The humidity value (14) in the display (2) changes automatically

after setting and shows the currently measured relative humidity again. The

device regulates the humidity of the room to be dehumidified and switches off

on reaching the set humidity. The device switches back on when the room

humidity increases. For continuous operation, set the humidity to < 30 % with

the buttons (15) until “CO” is shown in the humidity display (14). The humidity

is not regulated during continuous operation; the device dehumidifies perma-

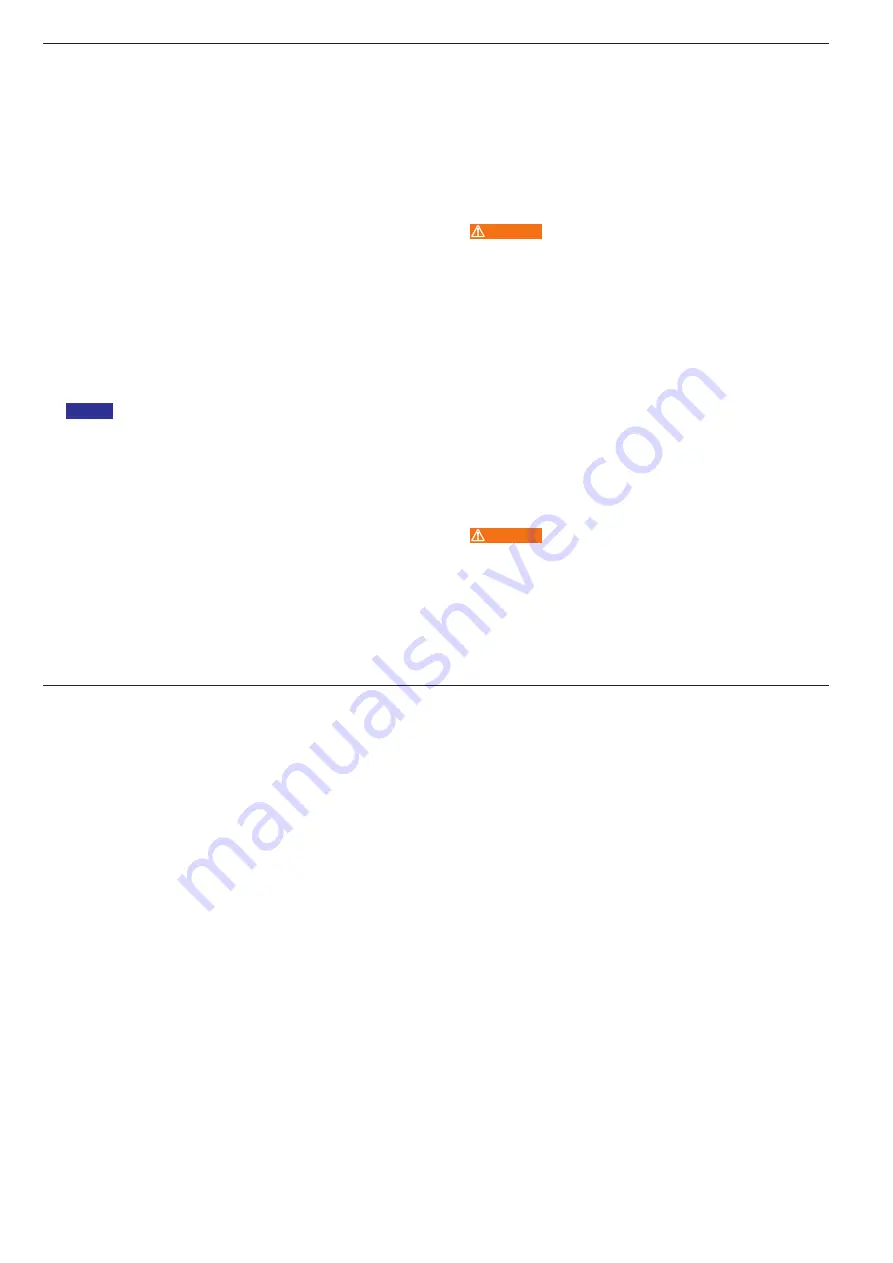

nently. When the condensation tank (9) (accessory, Art. No. 132100) is used,

the device switches off when the condensation tank is full. Then the “conden-

sation tank” symbol (6) and “E4” are shown in the display (2) and an acoustic

signal sounds intermittently. Empty the condensation tank and put it back in

(Fig. 5). Dehumidification is continued. There is no need to switch off the device

to empty the condensation tank. When using the condensation tank with pump

Scirocco 80 (accessory Art. No. 132121), the condensation tank is emptied by

the pump.

The memory function of the

ROLLER’S Scirocco 80 ensures that the set humidity

value is retained in the event of a power failure. The device then automatically

continues dehumidification/drying with the previously set value. The compressor

switches on with a delay of approx. 3 minutes for protection. The compressor

symbol (16) flashes in the display (2), but the fan starts immediately.

NOTICE

NOTICE

When draining the condensation into an external tank, it must be ensured that

this is emptied regularly and that the hose to the condensation drain (4) is laid

into the tank with a downward gradient. If the condensation is drained directly

into a drain pipe with a hose, this must also be laid with a downward gradient.

Also check whether the hose to the condensation drain (4) is inserted into the

opening of the condensation tank (9). Do not bend the hoses to the conden-

sation drain. If you do, the condensation will overflow over the edge of the

collection tray in the device and spill onto the floor.

The amount of condensation that forms is influenced by the temperature and

humidity of the room air. Recommended values in continuous operation:

30 °C (86 °F): 80 % r. h. = approx. 80 litres/day, 60 % r. h. = approx. 40 litres/day

20 °C (68 °F): 80 % r. h. = approx. 40 litres/day, 60 % r. h. = approx. 22 litres/day

15 °C (59 °F): 80 % r. h. = approx. 28 litres/day, 60 % r. h. = approx. 16 litres/day

10 °C (50 °F): 80 % r. h. = approx. 16 litres/day, 60 % r. h. = approx. 11 litres/day

(r. h. = relative humidity)

Water residue can drip from the condensation drain hose (4) after dehumidifi-

cation.

4. Maintenance

Notwithstanding the maintenance described below, it is recommended to send

in the electrical device to an authorised ROLLER contract customer service

workshop for inspection and periodic testing of electrical devices at least once

a year. In Germany, such periodic testing of electrical devices should be

performed in accordance with DIN VDE 0701-0702 and also prescribed for

mobile electrical equipment according to the accident prevention rules DGUV,

regulation 3 “Electrical Systems and Equipment”. In addition, the respective

national safety provisions, rules and regulations valid for the application site

must be considered and observed.

4.1. Maintenance

WARNING

WARNING

Pull out the mains plug before maintenance work!

Clean the device regularly especially when it has not been in use for a long

time. Store the device in a frost-proof location. Empty and clean the conden-

sation tank (9) as well as the condensation tank with pump .

Clean the air filter (Fig. 6 (28)) of

ROLLER’S Scirocco 50 regularly. Remove

the air filter in the direction of the arrow. Clean this with a suitable vacuum

cleaner or under running water. Renew the air filter if necessary. Let the air

filter dry before re-installing.

Clean the air filter mat of

ROLLER’S Scirocco 80 regularly. To do this, pull the

air filter flap (Fig. 3 (17)) which is fastened by a magnet. Pull out wire rods,

clean the air filter mat and the air filter flap (17) with a suitable vacuum cleaner

or under running water. Renew the air filter mat if necessary.

Clean plastic parts (e.g. housing) only with machine cleaner (Art. No. 140119)

or a mild soap and a damp cloth. Do not use household cleaners. These often

contain chemicals which can damage the plastic parts. Never use petrol,

turpentine, thinner or similar products for cleaning.

Make sure that liquids never get inside the device.

4.2. Inspection/Repair

WARNING

WARNING

Pull out the mains plug before carrying out maintenance or repair work!

This work may only be performed by qualified personnel.

Filling as well as inspection and repair work on a refrigerating device with

the inflammable R-290 refrigerant are not permitted. A specially equipped

working environment and special training for the service personnel are required

for filling and for inspection and repair work on refrigerating devices with

inflammable refrigerant. Compliance with this rule reduces property damage

and personal injuries.

eng eng

14