13

1.9. Vibrations (all types)

Weighted rms value of acceleration

< 2.5 m/s²

K = 1.5 m/s²

The indicated weighted effective value of acceleration has been measured against standard test procedures and can be used by way of comparison with another

device. The indicated weighted effective value of acceleration can also be used as a preliminary evaluation of the exposure.

CAUTION

CAUTION

The indicated weighted effective value of acceleration can differ during operation from the indicated value, dependent on the manner in which the device is used.

Dependent upon the actual conditions of use (periodic duty) it may be necessary to establish safety precautions for the protection of the operator.

2. Start-up

CAUTION

CAUTION

Transport weights above 35 kg must be carried by at least 2 persons, carry the

tool set separately. When transporting and installing the machine, please note

that the machine has a high centre of gravity with and without the base frame,

i.e. it is top heavy.

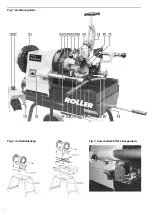

2.1. Installing ROLLER’S Robot 2U, 2K, 2D, ROLLER’S Robot 3U, 3K, 3D,

ROLLER’S Robot 4U, 4K, 4D

Remove both U-rails from the machine. Fix the machine to the oil tray. Push

the tool carrier into the guide arms. Push the pressing lever (8) from the rear

through the loop on the tool carrier and the clamping ring (10) onto the rear

guide arm so that the wing nut is facing the rear and the ring groove stays free.

Feed the hose with suction fi lter through the hole in the oil tray from the inside

and connect it to the coolant-lubricant pump. Push the other end of the hose

onto the nipple on the back of the tool carrier. Push the handle (9) onto the

pressing lever. Fix the machine to a workbench or subframe (accessory) with

the 3 screws provided. The machine can be lifted respectively at the front by

the guide arms and at the rear by a pipe clamped into a clamping and guide

chuck for transport. For transporting on the subframe, pipe sections Ø ¾" with

a length of approx. 60 cm are pushed into the eyes on the subframe and fi xed

with the wing nuts. If the machine is not to be transported, the two wheels can

be removed from the subframe.

Fill in 5 litres of thread cutting material. Insert chip tray.

NOTICE

NOTICE

Never operate the machine without thread cutting material.

Insert the guide bolt of the die head (12) into the hole of the tool carrier and

push on the die head with axial pressure on the guide pin and swivelling move-

ments as far as it will go.

2.2. Installing ROLLER’S Robot 2U-L, 2K-L, 2D-L, ROLLER’S Robot 3U-L, 3K-L,

3D-L, ROLLER’S Robot 4U-L, 4K-L, 4D-L (Fig. 2)

Fix the machine to a workbench or subframe (accessory) with the 4 screws

provided. The machine can be lifted respectively at the front by the guide arms

and at the rear by a pipe clamped into a clamping and guide chuck for transport.

Push the tool carrier into the guide arms. Push the pressing lever (8) from the

rear through the loop on the tool carrier and the clamping ring (10) onto the

rear guide arm so that the wing nut is facing the rear and the ring groove stays

free. Push the handle (9) onto the pressing lever. Hang the oil tray in the two

screws on the gear housing and push to the right into the slits. Hang the oil

tray in the ring groove on the rear guide arm. Push on the clamping ring (10)

until it is touching the suspension of the oil tray and clamp it tight. Hang the

hose with suction fi lter into the oil tray and push the other end of the hose onto

the nipple on the back of the tool carrier.

Fill in 2 litres of thread cutting material. Insert the chip tray from the rear.

NOTICE

NOTICE

Never operate the machine without thread cutting material.

Insert the guide bolt of the die head (12) into the hole of the tool carrier and

push on the die head with axial pressure on the guide pin and swivelling move-

ments as far as it will go.

2.3. Electrical connection

WARNING

WARNING

Caution: Mains voltage present! Before connecting the thread cutting machine,

Caution: Mains voltage present!

Caution: Mains voltage present!

check whether the voltage given on the rating plate corresponds to the mains

voltage.

Only connect the thread cutting machine of protection class I to

a socket/extension lead with a functioning protective contact. There is a

danger of electric shock. On building sites, in a wet environment, indoors and

outdoors or under similar installation conditions, only operate the thread cutting

machine on the mains with a fault current protection switch (FI switch) which

interrupts the power supply as soon as the leakage current to earth exceeds

30 mA for 200 ms.

The thread cutting machine is switched on and off with the foot switch (4). The

switch (3) serves to pre-select the direction of rotation or speed. The machine

can only be switched on when the emergency off button (5) is unlocked and

the thermal protection switch (6) on the foot switch is pressed. If the machine

is connected directly to mains (without a plug device), a 16 A circuit breaker

must be installed.

2.4. Thread-cutting Materials

For safety data sheets, see www.albert-roller.de → Downloads → Safety Data

Sheets.

Only use ROLLER thread cutting materials. They ensure perfect cutting results,

long life of the dies and considerably relieve stress on the tools.

NOTICE

NOTICE

ROLLER’S Smaragdol

High-alloy mineral oil-based thread-cutting material.

For all materials: steel,

stainless steel, non-ferrous metals, plastics. Can be washed out with water,

tested by experts. Mineral oil-based thread cutting materials are not approved

for drinking water pipes in different countries, e.g. Germany, Austria and Swit-

zerland. Mineral oil-free ROLLER’S Rubinol 2000 must be used in this case.

Observe the national regulations.

ROLLER’S Rubinol 2000

Mineral oil-free, synthetic thread-cutting material for

drinking water pipes.

Completely soluble in water. According to regulations. In Germany DVGW test

no. DW-0201AS2031, Austria ÖVGW test no. W 1.303, Switzerland SVGW test

no. 9009-2496. Viscosity at –10°C: ≤ 250 mPa s (cP). Pumpable up to –28°C.

Easy to use. Dyed red for checking washout. Observe the national regulations.

Both thread cutting materials are available in aerosol cans, canisters, barrels

as well as spray bottles (ROLLER’S Rubinol 2000).

NOTICE

NOTICE

All thread cutting materials may only be used in undiluted form!

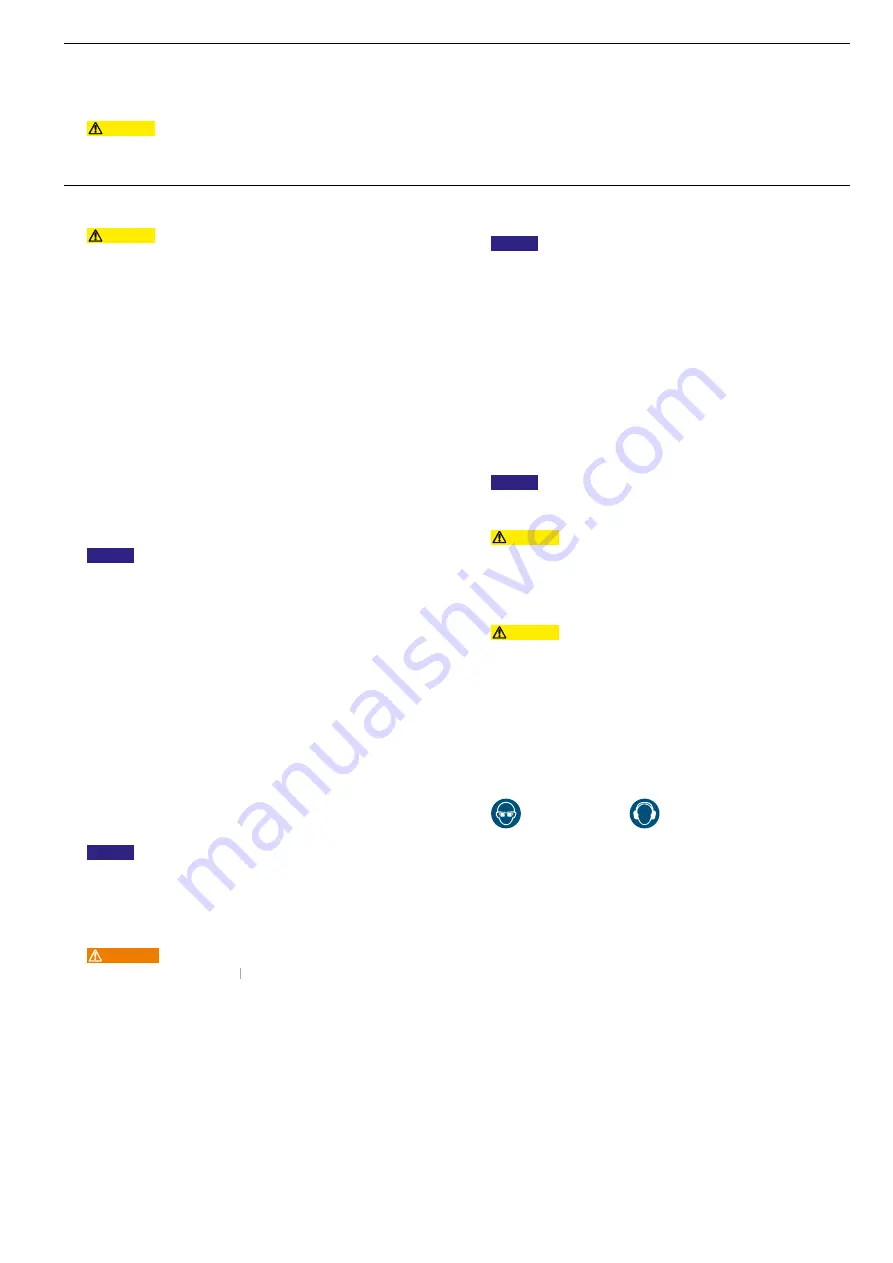

2.5. Material Support

CAUTION

CAUTION

Pipes and bars longer than 2 m must be supported additionally by at least one

height-adjustable ROLLER’S Assistant 3B, ROLLER’S Assistant XL 12" mate-

rial rest. This has steel balls for easy movement of the pipes and bars in all

directions without the material support tipping over.

2.6. Subframe, mobile and folding (accessory)

CAUTION

CAUTION

The folded subframe, mobile and folding, quickly moves up automatically without

mounted thread cutting machine after releasing. Therefore hold down the subframe

by the handle when releasing and hold with both handles when moving up.

To move up with the thread cutting machine mounted, hold the subframe with

one hand on the handle, put one foot on the cross member and release both

locking pins by turning the lever. Then hold the subframe with both hands and

move to working height until the two locking pins snap in. Proceed in the reverse

order to fold up. Drain the thread-cutting material from the oil tray or remove

the oil tray before unfolding or folding up.

3. Operation

Use eye protection

Use ear protection

3.1. Tools

The die head (12) is a universal die head. That means for all types of threads

for above mentioned sizes, divided in 2 tool sets, only one die head is required.

For cutting tapered pipe threads, the length stop (13) needs to be in the same

direction with the closing and opening lever (14). To cut cylindrical long threads

and bolt threads, the length stop (13) has to be folded away.

Changing the ROLLER’S dies

The ROLLER’S dies can be inserted or changed with the die head mounted

on the machine or detached (i.e. on a bench). Slacken clamping lever (15) but

do not remove it. Push the adjusting disc (16) at the handle away from the

clamping lever to the far end position. In this position the ROLLER’S dies are

put in or taken out. Ensure that the indicated size of thread shown on the back

of the ROLLER’S dies corresponds to the size of thread to be cut. Furthermore,

ensure that the numbers shown on the back of the ROLLER’S dies correspond

with those indicated on the die holder (17).

Insert the ROLLER’S dies into the die head as far as the ball inside the slot of

the die holder snaps in. Once all ROLLER’S dies are set, adjust the size of

thread by shifting the adjusting disc. Bolt thread must always be set to „Bolt“.

Clamp the adjusting disc with the clamping lever, close the die head by pressing

the closing and opening lever (14) down slightly to the right. The die head opens

either automatically (with tapered pipe threads), or at any time manually by

slight pressure to the left on the closing and opening lever.

If the holding power of the clamping lever (15) is insuffi cient (e.g. through blunt

ROLLER’S dies) when the 2½ – 3" and the 2½ – 4" die head is in use, due to

the increased cutting force applied, with the result that the die head opens

under cutting pressure, the capscrew on the side opposite the clamping lever

(15) must also be tightened.

eng eng