●

Electrical installation pipes DIN EN 50086 Ø 16 – 25 mm.

●

Composite pipes Ø 14 – 32 mm

Largest bending angle

180°

1.2. Speed

Arco

Arco 50

Akku-Arco

Speed infinitely

adjustable

0…4 rpm

0…1 rpm

0…3.33 rpm

1.3. Electrical data

ROLLER’S Arco,

230 V, 1~, 50/60 Hz; 1000 W; 4.8 A or

ROLLER’S Arco 50

110 V, 1~, 50/60 Hz; 1000 W; 9.6 A,

Intermittent service S3 15% (AB 2/14 min.),

double insulated, interference-suppressed.

ROLLER’S Akku-Arco

18 V = 2.0 Ah, 30 A

Rapid charger (1 h)

Input

220 – 240 V ~; 50 – 60 Hz; 65 W

Output 12 –18 V =

1.4. Dimensions (mm) Arco

Arco 50

Akku-Arco

L × W × H:

585×215×140

640×240×95

540×280×140

(23”×8½”×5½”) (25”×9½”×3¾”) (21¼”×11”×5½”)

1.5. Weights

Arco

Arco 50

Akku-Arco

Drive unit

8.3 kg

16.9 kg

9 kg (with batt.)

(18.3 lb)

(37.3 lb)

(19.8 lb)

Bending former

0.2..1.6 kg

4.44..7.8 kg

0.2..1.6 kg

(½ ..3½ lb)

(9.8..17.2 lb)

(½ ..3½ lb)

Back former

0.1..0.2 kg

0.25..0.42 kg

0.1..0.2 kg

(¼ ..½ lb)

(0.55..0.9 lb)

(¼ ..½ lb lb)

Insert bolt

0.4 kg (⅞ lb)

0.4 kg (⅞ lb)

0.4 kg (⅞ lb)

1.6. Noise information Arco

Arco 50

Akku-Arco

Emission at

workplace

82 dB (A)

90 dB (A)

90 dB (A)

1.7. Vibrations

Weighted effective value

of acceleration

2.5 m/s²

2.5 m/s²

2.5 m/s²

The indicated weighted effective value of acceleration has been measured

against standard test procedures and can be used by way of comparison with

another device. The indicated weighted effective value of acceleration can also

be used as a preliminary evaluation of the exposure.

Attention:

The indicated weighted effective value of acceleration can differ

during operation from the indicated value, dependent on the manner in which

the device is used. Dependent upon the actual conditions of use (periodic duty)

it may be necessary to establish safety precautions for the protection of the

operator.

2. Preparations for Use

2.1. Electrical connection

Pay attention to mains voltage! Check whether the voltage specified on the

rating plate matches the mains voltage before connecting the drive machine

or the rapid charger. Only operate the electrical device on the mains via a 30 mA

fault current protection device (FI switch) on building sites, out doors or similar

types of installation.

The battery and spare batteries delivered with the ROLLER’S Akku-Arco are

not charged. Charge the batteries before using for the first time. Only use the

ROLLER’S rapid charger (565220) for charging. When the battery is inserted

in the rapid charger the pilot light on the rapid charger flashes. The pilot light

stops flashing and lights steadily after approx. 1 hour meaning that the battery

is charged. The battery only reaches its full capacity after several charging

cycles.

2.2. Selecting the bending tools

ROLLER’S Arco, ROLLER’S Akku-Arco

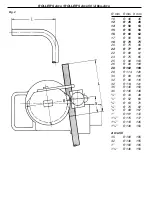

Put a bending former (1) (Fig. 1) corresponding to the pipe size onto the square

(2). The mounting is designed such that the bending former can only be fully

fitted in one direction. Place in readiness the back former (3) sui table for the

pipe size and the insert bolt (4).

ROLLER’S Arco 50, Ø 35 – 50

Put a bending former (1) (Fig. 1) corresponding to the pipe size onto the square

(12). The mounting is designed such that the bending former can only be fully

fitted in one direction. Place in readiness the back former (3) sui table for the

pipe size and the insert bolt (4). Insert the appropriate sized back former (3),

the support (11) and the insert bolt (4).

ROLLER’S Arco 50, Ø 10 – 40

Remove adaptor block (12) and replace with adaptor block (14) into the drive

unit. Put a bending former (1) (Fig. 1) corresponding to the pipe size onto the

square (14). The mounting is designed such that the bending former can only

be fully fitted in one direction. Insert the appropriate sized back former (3), the

support (13) and the insert bolt (4).

When using the ROLLER’S Arco 50, the support (11) and (13) respec tively

should be attached above the bending and back formers, for all sizes. Up

to and including sizes 24 R75 (¾” R75), the support (15) should also be

attached below. This is mounted on one side on the adaptor block collar

(14), and on the other side with the locating pin (16) in the outermost bore

hole of the support (15) marked out in the housing (see 3.1.).

The drive unit gets damaged when bending without this support!

3. Operation

3.1. Working procedure

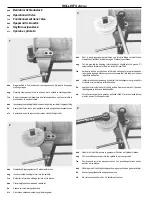

Turn changeover switch (7) to »L« (reverse). Press inching switch (8) while

gripping the motor handle (9) at the same time. The bending former turns

clockwise into its starting position in which the slipping clutch is effective.

Release the inching switch

immediately.

Do not put unnecessary load on the

clutch. Turn changeover switch (7) to »R« (forward). Place pipe into bending

former so that the pipe end projects at least 10 mm beyond the driver (10).

With the pipe sizes 22 to 50 mm, the pipe must be pressed into the radius of

the bending former. Lower the insert bolt (4) through the matching back former

(3) and into the corresponding hole bored in the machine.

When using the ROLLER’S Arco 50, the support (11) and (13) respec tively

should be attached above the bending and back formers, for all sizes. Up

to and including sizes 24 R75 (¾” R75), the support (15) should also be

attached below. This is mounted on one side on the adaptor block collar

(14), and on the other side with the locating pin (16) in the outermost bore

hole of the support (15) marked out in the housing (see 3.1.).

The drive unit gets damaged when bending without this support!

Ensure here that the insert bolt (4) for the sizes up to 22 mm (¾”) goes into the

left-hand locating hole (5) and for larger sizes into the right-hand hole (6).

Operate the inching switch (8) to bend the pipe. Towards the end of the required

bend, only press the switch lightly, so that the final point is approached slowly

and thereby precisely. A scale is provided on each bending former, together

with the mark on the back former, ensures precise manufacture of arcs of up

to 180° / Arco 50 up to 90°. Be aware that various materials spring back differ-

ently. If a 180° bend / Arco 50: 90° bend is produced and reaches the end

position, the slipping clutch comes into action again. Release the inching switch

immediately.

Turn changeover switch (7) to »L« (reverse). Allow the bending

former to run back a few deg rees until the pipe is unclamped by light pressure

on the inching switch (8). Pull out the insert bolt (4) and remove the bent pipe.

When bending on site, the bending former too can be taken off for easier

removal of the bent pipe.

Only allow the bending former to return to its starting position

after

removal of

the pipe, as otherwise the produced bend might be damaged. While bending

stainless steel pipes of pressfitting systems one must pay attention that the

mark at the pipe caused by the driver (10) does not lie in the sealing area of

the pressing joint.

3.2. Bending to size

If a bend is required at a certain point on the pipe, a lenght correction must be

made to suit the pipe size.

For a 90° bend, the correction dimension X given in Fig. 2 must be taken into

account. The set dimension L must be reduced by the amount X here. If the

dimension L should be 400 mm for the pipe size 22, the dimension line must

be made on the pipe at 320 mm. This line is then – as shown in Fig. 2 – to be

aligned with the 0-mark on the bending former.

3.3. Unit support ROLLER’S Arco, ROLLER’S Akku-Arco

Vertically adjustable unit supports on tripod (Art.No. 586100) and for mounting

on the work bench (Art.No. 586150) available as accessories.

4. Maintenance

Pull out the mains plug and remove the battery before maintenance and repair

work! This work must be carried out solely by specialists or persons familiar

with the unit.

4.1. Maintenance

ROLLER’S Arco, ROLLER’S Arco 50 and ROLLER’S Akku-Arco are maintenance-

free. The gearbox has a permanent grease filling and therefore requires no

lubrication.

4.2. Inspection/Servicing

The motor of the ROLLER’S Arco and ROLLER’S Arco 50 has carbon brushes.

These are subject to wear and must therefore be checked periodically and

replaced if necessary. To do so, unscrew the 4 screws on the motor handle

about 3 mm, pull the motor handle back and remove the two covers from the

motor housing. See also ”5. Action in Case of Trouble“.

5. Connection

In the ROLLER’S Akku-Arco make absolutely sure that the plus pole on the

motor (plastic base of the connecting tab with lug) is connected to switch terminal

1 with the red wire.

6. Trouble

6.1. Trouble:

Bending former stops during bending although the motor is

running.

Cause:

●

Pipe being bent has walls too thick.

●

Slipping clutch worn.

●

Carbon brushes worn.

●

Battery empty (ROLLER’S Akku-Arco).

eng

ROLLER’S Arco / ROLLER’S Arco 50 / Akku-Arco

eng