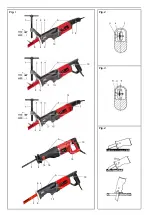

2. Preparations for Use

2.1. Electrical connection

WARNING

Note the mains voltage! Before connecting the ROLLER'S reciprocating saw

Note the mains voltage!

Note the mains voltage!

or the rapid charger, check whether the voltage given on the rating plate corre-

sponds to the mains voltage. On building sites, in a wet environment, indoors

and outdoors or under similar installation conditions, only operate the power

tool on the mains with a fault current protection switch (FI switch) which inter-

rupts the power supply as soon as the leakage current to earth exceeds 30 mA

for 200 ms.

2.2. Sawing with guide holder (2) (right-angled sawing)

WARNING

Pull out the mains plug or remove the battery before fi tting/removing the

guide holder!

Push the bearing pin (3) of the guide holder (2) into the ROLLER'S reciprocating

saw from the side so that the limit pin of the guide holder runs in the longitudinal

slit in the ROLLER'S reciprocating saw.

NOTICE

The guide holder must be used to achieve

right-angled saw cuts because

exact right-angled positioning and guiding of the ROLLER'S reciprocating saw

is not possible by hand.

2.3. Hand-guided sawing

The ROLLER'S reciprocating saw is used without a guide holder (2). It must

be pressed forcefully against the material when sawing so that the support

shoe (6) is constantly in contact with the material being sawn. The material to

be sawn must be secured against being fl ung away.

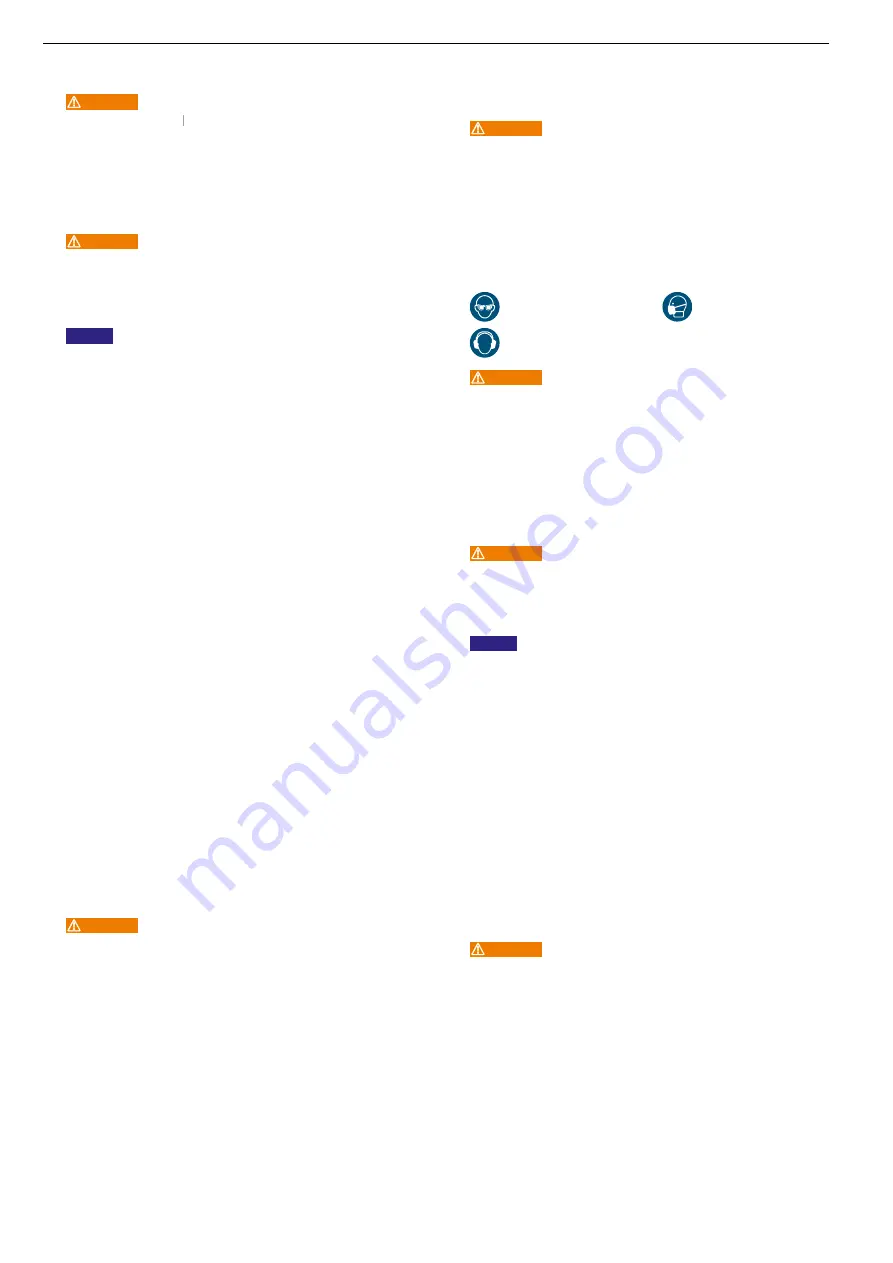

2.4. Selecting the suitable saw blade

In your own interest, use only ROLLER'S quality saw blades for all ROLLER'S

reciprocating saws otherwise your warranty rights will be voided!

ROLLER'S special saw blades 2"/140-3.2, 4"/200-3.2 and 6"/260-3.2

(Fig. 8) for all ROLLER'S Fox models

Developed especially for ROLLER'S Fox. Absolutely essential for right-angled

sawing and fast disassembly of steel pipes with force-transmitting guide holder.

This produces multiple thrust pressure by a fi ve-fold force-transmitting leverage.

ROLLER'S special saw-blades with double-sided hinge with extra wide clamping

surface for exact seat, extra thick, rigid and unbendable for high stability. Coarse,

corrugated teeth for fast cutting. Much longer service life. Normal saw blades

with one-sided hinge are useless for right-angled sawing with a guide holder

because they break at the clamping point due to high thrust pressure.

ROLLER'S special saw blade 150/200/300 (Fig. 8) for all ROLLER'S Fox,

ROLLER'S Carat models

For free-hand sawing and sawing with force-transmitting guide holder. Only 1

ROLLER'S special saw blade for all sawing work instead of many different saw

blades. Tenacious material, highly fl exible, also for wall-fl ush sawing. Double-

sided hinge with extra wide clamping surface for exact seat and high stability.

Alternating tooth pitch (combi-teeth), very highly hardened in the teeth area.

Excellent sawing performance and very long service life as a result. Also for

materials that are diffi cult to cut, e.g. stainless steel pipes, hard cast iron pipes

etc. and for sawing wood with nails, pallets. Normal saw blades with one-sided

hinge are useless for the high thrust pressure when sawing with a guide holder;

they break at the clamping point.

ROLLER'S saw blades for all ROLLER'S reciprocating saws

For special sawing work with metals, wood, building materials and plastics

numerous ROLLER'S saw blades or different shape, length and tooth pitch

with conventional (one-sided) hinge are available: See saw blade table Fig. 8.

2.5. Fitting the saw blade

WARNING

Pull out the mains plug before fi tting/removing the saw blade!

All ROLLER'S Fox, ROLLER'S Carat models (Fig. 2 and Fig. 3)

Do not place the ROLLER'S reciprocating saw on

the anti-kink sleeve of the

connecting lead to fi t the ROLLER'S saw blade, otherwise it will be damaged!

Loosen the clamping screw (9) of the saw blade pressure piece (4) until the saw

blade can be inserted over the centring pin. The ROLLER'S special saw blade

is between the two arms of the U-shaped saw blade pressure piece (Fig. 2).

ROLLER'S saw blades with conventional (single) tang must lie within the recess

in the base of the saw blade pressure piece (Fig. 3). Screw the saw blade pres-

sure piece

tight with the clamping screw (9) otherwise the centring pin will be

damaged or sheared off. The centring pin does not have the task of holding the

saw blade. This is done exclusively by clamping with the clamping screw (9). If

the clamping screw (9) can no longer be tightened because its socket head or

the Allen key is worn, the centring pin shears off. Therefore renew a worn clamping

screw (9) and Allen key in good time.

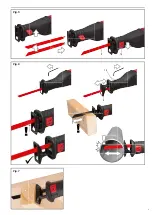

ROLLER'S Shark VE (Fig. 5.)

Do not place the ROLLER'S reciprocating saw on

the anti-kink sleeve of the

connecting lead to fi t the ROLLER'S saw blade, otherwise it will be damaged!

Swing up the saw blade clamping lever (14) by hand and hold it. Insert the saw

blade (5) either with the teeth facing down or turned 180° facing up. Release

the saw blade clamping lever (14), this is spring-loaded and clamps the saw

blade automatically. Check the saw blade (5) for tight fi t. The saw blade turned

upwards allows sawing cuts near to a surface (Fig. 7.)

2.6. Setting the length-adjustable support shoe, ROLLER'S Shark VE (Fig. 6.)

WARNING

Pull out the mains plug before adjusting the length-adjustable, tiltable

support shoe (6)!

Take the Allen key out of the holder (15) and undo the two clamping screws

(16). The tiltable support shoe (6) can be adjusted steplessly by 40 mm in

longitudinal direction. Set the desired position, tighten the clamping screws

(16), insert the Allen key in the holder (15). This adjustment possibility allows

better utilisation of partially blunt saw blades and prevents the tip of the saw

blade from hitting a wall/inside of a pipe (take saw blade stroke into consid-

eration).

3. Operation

Use eye protection

Use a respirator

Use ear protection

WARNING

Suitable dust extractors, a respirator and disposable overalls must be used for

work which could produce health hazardous dusts. Observe the national regu-

lations.

ROLLER'S Fox ANC: Switch on/off with on/off safety switch (7).

ROLLER'S "VE" reciprocating saws: Stepless electronic stroke speed control

by variable pressure on the stepless safety switch (accelerator switch) (10).

ROLLER'S Fox ANC SR: Stepless electronic stroke speed control. Preselec-

tion of the desired number of strokes at the thumbwheel (12). Switch on/off

with on/off safety switch (7).

3.1. Work procedure for sawing with a guide holder

WARNING

Only hold the ROLLER'S reciprocating saw by the insulated handles ("A") (Fig.

1), not on the guide holder (2), when performing work where the tool can come

into contact with concealed electric cables or its own power cable. Contact with

a live cable can also put metal tools or the guide holder under voltage and lead

to electric shock.

NOTICE

Only use ROLLER'S special saw blades (see 2.4.). Normal saw blades with

one-sided hinge are useless for right-angled sawing with a guide holder because

they break at the clamping point due to high thrust pressure.

Fit the guide holder as described in 2.2. Place the ROLLER'S reciprocating

saw with guide holder on the pipe so that the clamping spindle with toggle (1)

is vertical. Tighten the clamping spindle. Press the switch (7 or 10) at the same

time as grasping the motor handle or actuate the lever with latch (11) and pull

up the ROLLER'S reciprocating saw until the pipe or profi le is sawn through.

The start of sawing can be improved especially with large diameters (e.g. 4")

by not switching on the ROLLER'S reciprocating saw until the saw blade is

already in contact with the pipe. Make sure that the prism of the guide holder

is always kept free from chips, otherwise the right-angled cut will be impaired.

To achieve optimum sawing speed and to preserve the saw blade, only select

medium thrust pressure. Heavy thrust pressure does not increase the sawing

speed! ROLLER'S Fox ANC is equipped with an overload protection (8). This

is triggered when the thrust pressure is too great; the button jumps out slightly

and the ROLLER'S reciprocating saw stops. After a few seconds the overload

protection can be pushed back in and the ROLLER'S reciprocating saw can

be switched back on.

3.2. Work procedure for hand-guided sawing

WARNING

Only hold the ROLLER'S reciprocating saw by the insulated handles ("A") (Fig.

1) when performing work where the tool can come into contact with concealed

electric cables or its own power cable. Contact with a live cable can also put

metal tools under voltage and lead to electric shock.

For straight or curved cuts press the tiltable support shoe (6) forcefully against

the material so that the tiltable support shoe (6) is constantly in contact with

the material to be sawn. Switch on the ROLLER'S reciprocating saw. Only use

sharp and fl awless saw blades. Even thrust pressure reduces the risk of acci-

dent and is kind on the ROLLER'S reciprocating saw and the saw blade. Always

feed the connecting lead back away from the ROLLER'S reciprocating saw.

Keep the ROLLER'S reciprocating saw pressed forcefully against the material

to be sawn during sawing. If the saw blade jams whilst sawing, switch off the

ROLLER'S reciprocating saw, widen the sawn cleft with a suitable tool and pull

out the saw blade.

For plunge-cut sawing in material that is not too hard, e.g. wood, plastic, plastic

pipes or alloy pipes, the saw blade can be plunged carefully into a surface

whilst sawing (Fig. 4). Use a short saw blade. Place the switched off ROLLER'S

reciprocating saw with the bottom edge of the tiltable support shoe (6) and the

tip of the saw blade at the cutting point, switch on the ROLLER'S reciprocating

eng eng

12

Summary of Contents for Akku-Carat 22V VE

Page 24: ...Fig 5 Fig 7 Fig 6 14 5 6 16 3...