parts, breakage of parts, mounting, and any other condition that may affect

the power tool's operation. A guard or other part that is damaged should be

properly repaired or replaced by an authorised service facility unless other-

wise indicated in the operating instructions. Have defective switches replace

by an authorised service facility. Do not use the unit if the switch does not

turn it on and off.

·

Warning

Only use genuine spare parts and accessories, for personal safety reasons,

to ensure correct operation of the machine. The use of other accessories

or attachments involves a risk of injury.

·

Have your unit repaired by an authorised service facility

This unit complies with the relevant safety. All maintenance and repair work,

particularly when involving the electrical systems, must be performed only

by specialist personnel or by persons familiar with the machine and by using

original spare parts, otherwise injuries may result to the user. All unautho-

rised modifications of the machine are prohibited for safety reasons.

Specific Safety Instructions

·

Wear gloves suitable against cold temperatures.

·

Ice causes burns upon contact with skin. After work is finished, let deep-

freezer heads thaw out.

·

Do not bend or twist hoses or subject them to tensile stress. This can lead

to leaks.

·

Do not open up the refrigerant circuit. The apparatus contains the refri-

gerant R 404A in a closed circuit. Should refrigerant leak out in the event

of defective apparatus (e.g. breakage of a refrigerant hose), then the follo-

wing must be taken into consideration:

– Do not inhale: Get those affected into the fresh air and let them rest.

Should their breathing stop, use artificial respiration and call a physician.

– After contact with the skin: Thaw out or wash off affected portions of

skin with warm water.

– After contact with eyes: Rinse out thoroughly for 10 minutes with clean

water; call a physician.

– After swallowing: Do not induce regurgitation. Wash out mouth with

water, drink a glass of water. Go to a physician.

– Notice for physician: Do not administer any drugs of the Ephedrine /

adrenalin group.

Attention: In case of thermal decomposition of the refrigerant (e.g. fire)

highly noxious and corrosive vapours are generated.

·

Observe safety tips for refrigeration systems.

·

When scrapping the apparatus, dispose of the refrigerant properly.

·

Refrigerant may not be allowed to get into sewers, basements or work pits.

Refrigerant vapours may create a suffocating atmosphere.

1. Technical data

1.1. Article numbers

Deep freezer insert

1

/

8

(10, 12 mm) (pair)

131110

Deep freezer insert 1

1

/

4

(42 mm) (pair)

131155

Deep freezer insert 1

1

/

2

(pair)

131156

Deep freezer insert 54 mm (pair)

131157

Deep freezer insert 2

(60 mm) (pair)

131158

LCD digital thermometer

131115

Tightening strap

131104

Water squirt bottle

093010

1.2. Working range

Deep freezing liquids of all kinds such as,

e.g. water, milk, beer in tubes of steel,

copper, cast iron, lead, aluminium,

plastic, etc

1

/

8

–2

or 10–60 mm

Ambient temperature

+10°C up to +32°C

1.3. Electric data

Rated voltage, frequency, power, current

230 V~; 50 Hz, 430 W; 1.81 A

Safety class 1

Earthed conductor required

Safety type

IP 33

1.4. Refrigerant data

Refrigerant

R 404 A

Volume quantity

0.150 kg

Refrigerant circuit operating pressure

27 bar

1.5. Dimensions

Apparatus

310 × 305 × 360 mm

(12

× 12

× 14

)

Refrigerant hosing length

2 m

1.6. Weight

Apparatus

22.3 kg (50 lbs)

1.7. Noise information

Workplace-related emission reading

70 dB(A)

1.8. Vibrations

Weighted effective acceleration reading

2.5 m/s²

2. Preparations for Use

Deep freezing occurs by means of a transfer of refrigeration from the deep-

freezer heads to the outer surface of the tubing. To ensure good contact tran-

sition, paint, rust or other pollutants should be removed from the tubing. De-

formed tubes cannot be frozen up.

The water (or other liquid) in the tubing can only freeze up if there is no flow,

i.e. pumps should be turned off, water removal should be avoided. Cool off

water in the heating tubes to ambient temperature before deep freezing.

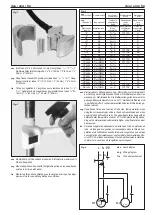

2.1. Mounting of the deep freeze heads

With tube sizes

1

/

4

–1

resp. 14–35 mm the deep-freezer heads are placed

directly against the tube (Figure 1). Fasten deep-freezer heads with the tighte-

ning strap (Figure 2). Shortest freezing times will be achieved when the hose

connector at the deep-freezer head is pointing upwards.

2.2. Using the deep freezer inserts

For tube sizes

1

/

8

(10, 12 mm), 1

1

/

4

(42 mm), 1

1

/

2

, 54 mm, 2

(60 mm) deep-

freezer inserts (accessories) are required (Figure 1). The latter are placed in

the deep-freezer heads. Each application can be seen in the table (Fig. 3).

Fasten deep-freezer heads with deep-freezer inserts to the tube with the tigh-

tening strap (Figure 2).

3. Operation

Turn the apparatus on only if the deep-freezer heads have been mounted. For

improving refrigeration transfer from the deep freezer heads to the tube, du-

ring the deep freezing process water should be sprayed between the deep

freezer head and the tube (Figure 2) several times with the water squirt bottle.

Important: It does not make sense to spray onto the point of freezing at the

beginning of the freezing process because the water runs away. When deep

freezing begins, water should be sprayed intensively in order to fill the gap

between the deep-freezer head and the pipe. If not followed, higher deep-freeze

times apply. After a certain period of deep freezing, frost forms on the tube in

the vicinity of the deep-freezer heads. When using the deep-freezer inserts for

the larger tubing sizes, make sure to spray until the transition between the deep-

freezer insert and the tubing is completely frozen. Should this frost formation

not occur within the period given in the table, then this strongly suggests flowing

water in the tubing or that the tube contents are hot. Where applicable, pumps

should be turned off, prevent water leakage, let water cool off. In addition, take

care that the deep-freezer heads are not subjected to solar radiation or hot air

draughts. In particular, air emissions from the apparatus valves should not be

allowed to blow on the deep-freezer point.

As accessories, LCD digital thermometers are available which can be inserted

into pockets on the tightening strap and which facilitate assessment of the deep-

freezer point's condition. The thermometers are driven by a battery which can

be replaced as needed.

Attention: The deep-freezer heads and the refrigerant hoses attain tempera-

tures of –30°C. Wear suitable gloves against cold temperatures.

According to the deep-freeze times indicated in the Table (Figure 3), repair

work can be done on the tubing. Before beginning repair work, check if the tu-

bing has depressurised. For this purpose, open any eventual let-off valves or

loosen a fastener. Do not turn apparatus off during repair process.

The deep-freeze times indicated in the Table (Figure 3) are ball-park values

and apply at an ambient / water temperature of about 20°C. At higher ambient

/ water temperatures, the time periods are accordingly extended. With plastic

tubing depending on the material used, substantially higher deep-freeze times

must be expected.

eng

eng