eng

eng

f) Dress properly. Do not wear loose clothing or jewellery. Keep your

hair, clothing and gloves away from moving parts.

Loose clothes,

jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly

used.

Use of these devices can reduce dust related hazards.

h) Only allow trained personnel to use the power tool.

Apprentices

may only operate the power tool when they are over 16, when this is

necessary for their training and when they are supervised by a trained

operative.

D) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your

application.

The correct power tool will do the job better and safer at

the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous

and must be repaired.

c) Disconnect the plug from the power source before making any

adjustments, changing accessories, or storing power tools.

Such

preventive safety measures reduce the risk of starting the power tool

accidentally.

d) Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to

operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for misalignment or binding of

moving parts, breakage of parts and any other condition that may

affect the power tools operation. If damaged, have the power tool

repaired by a qualified expert or by an authorised ROLLER after-

sales service facility before use.

Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools

with sharp cutting edges are less likely to bind and are easier to control.

g) Secure the workpiece.

Use clamps or a vice to hold the workpiece.

This is safer than holding it with your hand, and also it frees both hands

to operate the equipment.

h) Use the power tool, accessories and tool bits etc., in accordance

with these instructions and in the manner intended for the particu-

lar type of power tool, taking into account the working conditions

and the work to be performed.

Use of the power tool for operations

different from those intended could result in a hazardous situation. All

unauthorised modifications to the power tool are prohibited for safety

reasons.

E) Battery tool use and care

a) Ensure the switch is in the off position before inserting battery

pack.

Inserting the battery pack into power tools that have the switch

on invites accidents.

b) Recharge only with the charger specified by the manufacturer.

A

charger that is suitable for one type of battery may create a risk of fire

when used with another battery pack.

c) Use battery tools only with specifically designated battery packs.

Use of any other battery packs may create a risk of injury and fire.

d) When battery pack is not in use, keep it away from other metal

objects like paper clips, coins, keys, nails, screws, or other small

metal objects that can make a connection from one terminal to

another.

Shorting the battery terminals may cause bums or a fire.

e) Under abusive conditions, liquid may be ejected from the battery,

avoid contact. If contact accidentally occurs, flush with water. If

liquid contacts eyes, additionally seek medical help. Liquid ejec-

ted from the battery may cause irritation or bums.

f) Do not use the battery/charger at battery/charger temperatures or

ambient temperatures of

5°C/40°F or

b

40°C/105°F.

g) Do not dispose defective batteries in the normal domestic waste.

Take them to an authorised ROLLER after-sales service facility or

to a reputed waste disposal company.

F) Service

a) Have your power tool serviced by a qualified repair person using

only identical replacement parts.

This will ensure that the safety of

the power tool is maintained.

b) Comply with maintenance instructions and instructions on tool re-

placements.

c) Check mains lead of power tool regularly and have it replaced by a

qualified expert or an authorised ROLLER after-sales service

facility in case of damage. Check extension cable regularly and

replace it when damaged.

Specific Safety Instructions

•

Do not overload the sawblade and saw. Do not use damaged

sawblades. Do not apply excessive feed pressure.

•

Attention! Cut parts become warm.

•

Machine not suited for dust generating jobs.

•

Wear ear protectors.

•

Never operate the saw without its safety cover.

•

Wear cloves when touching saw blades and rigid materials (saw

blades must be carried in a box whenever practicable).

•

Failures of the machine, including the protection devices or saw

blade, must be reported to the responsible person for safety when-

ever discovered.

•

The floor in the vicinity of the machine must be even, clean and free

from loose particles, e.g. chips and cutting waste.

•

Do not remove cutting waste or other material from the cutting area

as long as the machine is running and the sawing aggregate still in

motion.

•

ROLLER’S cooling lubricants in spray cans (ROLLER’S Smaragdol,

ROLLER’S Rubinol 2000) are environment-friendly but contain combu-

stible propellant (butane). Spray cans are pressurized-do not force

open. Also, protect them from exposure to strong sunlight and heating

above 50°C.

•

Due to the degreasing effect of the cooling lubricants (thread-cutting

oils), an intensive skin contact has to be avoided. An appropriate skin

protector has to be applied.

•

Due to hygienical reasons the trough has to be cleaned regularly from

dirt and chips, at least, however, once a year.

•

It is not required to check the cooling lubricant because, due to the

consumption, new cooling lubricant is refilled from time to time.

•

Do not allow undiluted cooling lubricant to get into drainage, water

systems or the soil. Remaining cooling lubricants have to be delivered

to specialized waste disposal companies. Disposal identity number for

mineral-based cooling lubricants 54401, for synthetic 54109.

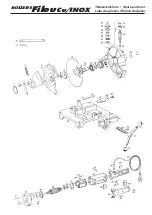

1. Technical data

1.1. Article numbers

ROLLER’S Filou K drive unit

849000

ROLLER’S Filou K with automatic cooling lubricant unit

849007

ROLLER’S Filou Cu-INOX circular pipe saw

for dry-sawing

849006

ROLLER’S universal circular metal saw blade

HSS, 225x2x32, 120 teeth

849700

ROLLER’S circular metal saw blade

HSS especially for stainless steel pipes,

fine toothing, 225x2x32, 220 teeth

849703

ROLLER’S circular metal saw blade HSS-E (cobalt alloyed),

especially for stainless steel pipes, fine toothing,

225x2x32, 220 teeth. Very long life.

849706

Ring spanner WAF 27/17

849112

Allen-key

074005

ROLLER’S Assistent stock support

120000

1.2.1. Working range ROLLER’S Filou K

Sawblade

Ø 225 mm

Max. cutting depth

78 mm

Cross-sections:

pipe, section, solid

Materials:

steel, stainless steel, non-ferrous

metal, light metal, plastic etc. up to a

strength of approx. 1000 N/mm²

Right-angled cuts and bevel cuts up to 45°

1.2.2. Working range ROLLER’S Filou Cu-INOX

Sawblade

Ø 225 mm

Stainless steel pipes, copper pipes and other materials

Ø

76 mm

<)

90°

±

78

55

70×50

50×50

40

40

50×30

45°

²

60

55

60×40

50×50

40

40

50×30