eng

eng

1.3.1. Speed/cutting rate ROLLER’S Filou K

Sawblade speed, no-load

115 rpm

Sawblade speed, full-load

73 rpm

Cutting rate at full load

52 m/min

1.3.2. Speed/cutting rate ROLLER’S Filou Cu-INOX

Sawblade speed, no-load

60 rpm

Sawblade speed, full-load

40 rpm

Cutting rate at full load

28 m/min

1.4.1. Electrical data ROLLER’S Filou K

230 V 1~; 50-60 Hz; 1200 W; 5.7 A or

110 V 1~; 50-60 Hz; 1200 W; 11.4 A;

fuse (mains) 10 A (B), intermittent operation S3 20% (AB 2/10 min),

all-insulated, interference-suppressed.

1.4.2. Electrical data ROLLER’S Filou Cu-INOX

230 V; 50-60 Hz; 500 W; 2.5 A or 110 V; 50-60 Hz; 500 W; 5.0 A;

fuse (mains) 10 A (B), intermittent operation S3 20% (AB 2/10 min),

all-insulated, interference-suppressed.

1.5. Dimensions

LxWxH:

425x490x600 mm (16

3

/

4

” x 19

1

/

3

” x 23

2

/

3

”)

1.6. Weights

ROLLER’S Filou K

22 kg (48 lbs)

ROLLER’S Filou Cu-INOX

17 kg (37 lbs)

1.7. Noise data

Workstation-related emission data

90 dB (A)

Sound capacity level

105 dB (A)

1.8. Vibrations

Weighted effective value of acceleration

ROLLER’S Filou Cu-INOX

12.2 m/s

2

ROLLER’S Filou K

20.1 m/s

2

2. Commissioning

Do not carry the machine by the motor handle, but with both hands on the

stand.

2.1. Electrical connection

Note the mains voltage! Before connecting the machine, check

whether the voltage on the rating plate matches the mains voltage. If

you work with cooling lubricant or in humid environment, the machine

has to be run with a residual current – operated circuit – breaker

(a.e.: earth leakage circuit breaker, FI-breaker 30 mA).

2.2.1. Setting up ROLLER’S Filou K

Attachment to workbench by four M 10 bolts (length 20 mm plus

worktop thickness) from underneath into the cooling lubricant

container.

Fill the cooling lubricant container (14) with the supplied cooling

lubricant ROLLER’ Smaragdol (2 liters).

For drinking water pipes use ROLLER’S Rubinol 2000. To empty the

coolant lubricant container detach the short hose section of the

coolant lubricant pump from the gear unit housing, hold it in a

container, and switch on the machine.

2.2.2. Setting up ROLLER’S Filou Cu-INOX

Attachment to workbench by four M 10 bolts (length 65 mm plus

worktop thickness) and nuts.

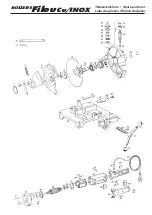

2.3. Mounting (changing) the sawblade

Pull out the mains plug!

While making a selection of a sawblade, please note that the space of

the toothing shall be smaller than the wall thickness of the material to

be cut. Otherwise the sawblade gets jammed and breaks.

Unhook the tension spring (1) using a screwdriver. Disconnect the

connecting strap (3). Remove the four screws from the safety cover

(4) using the supplied Allen key and take off the complete safety

cover (4) to the front (do not dismantle it!). Undo the hex. nut for

fastening the sawblade (right-hand thread) using the supplied ring

spanner, size WAF 27. Remove the shim. Insert (change) the

sawblade (7).

Important! Only use genuine ROLLER’S universal circular

sawblades!

The extra holes in the sawblades for the ROLLER’S Filou are

arranged offset, so that the sawblade can only be fitted with its teeth

pointing in the sawing direction.

Fit the shim, tighten the hex.nut, on no account omit to fit the safety

cover (risk of accidents). Attach the tension spring (1) and the

connecting strap(3).

3. Operation

Important:

Chuck material savely! Apply moderate feed pressure!

3.1. Operating sequence

Chuck the material such that the mark on the visor (6) is above the

required parting point. Clamp the material with the chucking lever

(16). Do not chuck excessively, particularly thin-walled pipes, to avoid

oval deformation. Otherwise, during operation, tensions will break free

which could lead to a breakage of the sawblade. Operate the fingertip

switch in the feed handle (2) and saw through the material. If the

material to be chucked is less than half the width of the vice, a stock

of identical size must be placed in the empty side of the vice so that

the vice holds the material parallel. If, e.g. due to a resharpened

sawblade, the workpiece cannot be thoroughly cut, a support is to be

put under the workpiece.

ROLLER’S Filou K: For thin-walled pipes use clamp insert (Art.No.

849170)!

3.2. Material support

Long bar stock must be supported using the ROLLER’S Assistent

(Art.No. 120000).

3.3. Cooling lubricant (ROLLER’S Filou K)

If operation is with an automatic cooling lubricant unit, cooling and

lubrication must be with ROLLER’S Smaragdol or ROLLER’S Rubinol

2000 (for drinking water pipes). These cooling lubricants ensure a tidy

sawing cut, long life of the sawblades and a smooth sawing sequence.

3.4. Length stop (ROLLER’S Filou K)

If several parts of identical length have to be sawn off, the length stop

can be set to the required part length in the range from 5 to 300 mm.

To do so, loosen the clamping bolt (11), position the length stop to the

required part length, and retighten the clamping bolt.

3.5. Sawing bevels (ROLLER’S Filou K)

Release the clamping lever (8) on the bearing block (10). Set the

bevel angle using the scale (9). Tighten the clamping lever. The positi-

on of the clamping lever handle can be changed by lifting the handle

vertically upwards and turning it.

3.6. Sawing of hard-to-machine materials (ROLLER’S Filou K)

To saw stainless steel, use the electronic speed control (Art.No.

565051). Cool and lubricate with ROLLER’S Smaragdol or

ROLLER’S Rubinol 2000 (for drinking water pipes).

According to the regulations of pipe manufacturers, stainless steel

pipes of pressfitting-systems have to be dry-cut. For this, apply

ROLLER’S Filou Cu-INOX (Art.No. 849005) with ROLLER’S circular

metal sawblade HSS, especially for stainless steel pipes.

4. Maintenance

Pull out the mains plug before any servicing or repair work! Such work

must be carried out only by experts and trained personnel.

4.1. Servicing

The ROLLER’S Filou is maintenance-free. The gear unit runs in a

permanent grease filling and therefore requires no lubrications.

4.2. Inspection/maintenance

The motor of the ROLLER’S Filou has carbon brushes. As these are

subject to wear, they must be checked and if nessesary replaced from

time to time. To do so, undo the 4 bolts on the motor handle by

approx. 3 mm, pull the motor handle to the rear and remove the two

covers from the motor housing. See also 5. Action in the event of

faults.

5. Action in the event of fault

5.1. Fault

Saw stops during sawing